Well Evaluations & Completions Technique

$5500.00

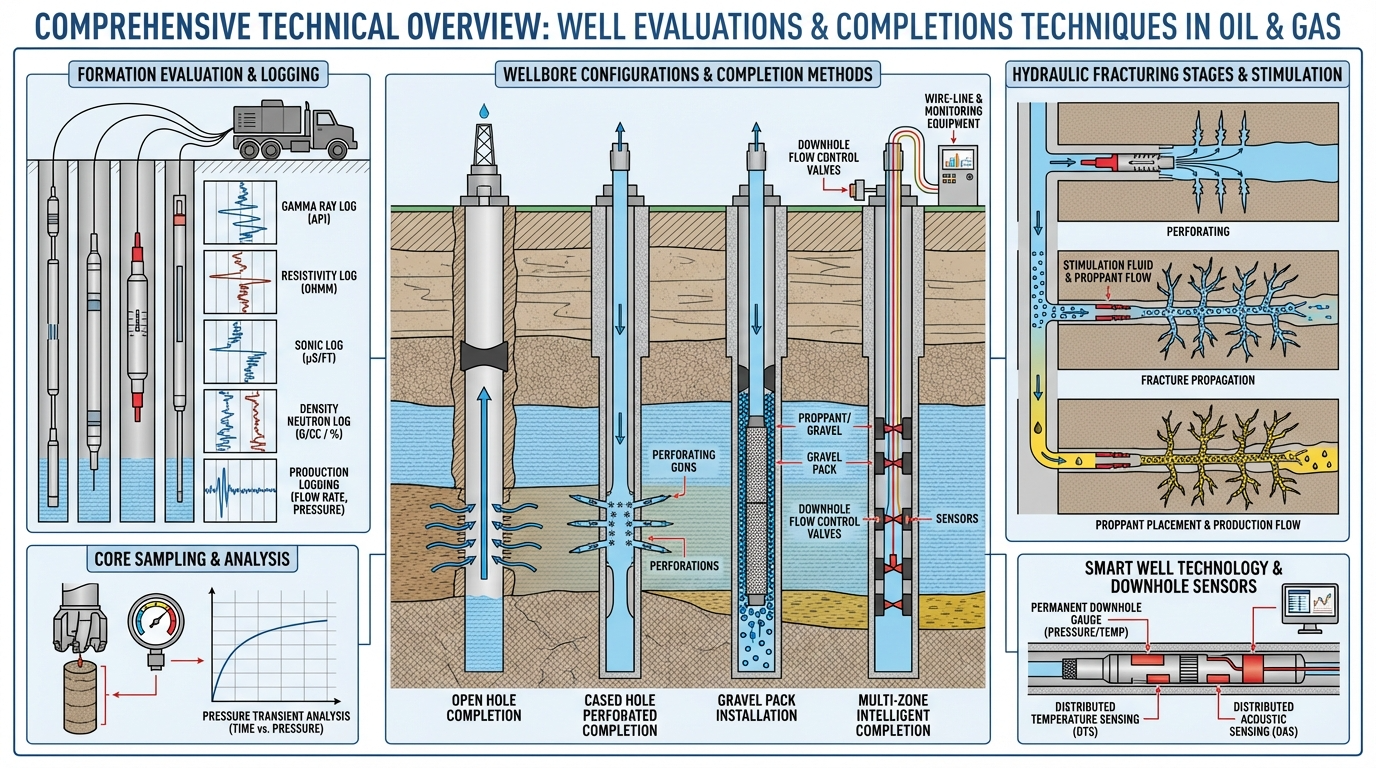

Well Evaluations & Completions Technique: 5-Day Professional Training Course

Course Overview

This intensive 5-day training program provides comprehensive knowledge of well evaluation methods and advanced completion techniques for maximizing well productivity and asset value. Specifically designed for professionals in the Kingdom of Saudi Arabia (KSA), Oman, GCC countries, and Africa, this course covers formation evaluation, petrophysical analysis, completion design, intelligent well systems, and intervention operations essential for optimizing hydrocarbon recovery in diverse reservoir conditions.

Target Audience

Completion engineers and supervisors

Production engineers and reservoir technologists

Petrophysicists and formation evaluation specialists

Drilling engineers involved in completions

Well intervention and workover engineers

Reservoir engineers requiring completion knowledge

Operations geologists and production geologists

Technical professionals from Saudi Aramco, PDO, ADNOC, and African operators

Petroleum engineering graduates

Asset integrity and well integrity specialists

Day 1: Formation Evaluation Fundamentals

Morning Session: Wireline Logging and Petrophysics

Module 1.1: Introduction to Formation Evaluation

Formation evaluation role in upstream operations

Evaluation workflow: drilling to production

Integration with geology, drilling, and reservoir engineering

Data acquisition timeline and decision points

Real-time vs. post-drill evaluation

Evaluation objectives: exploration, appraisal, development

Cost-benefit analysis of evaluation programs

Regional evaluation challenges in Middle East and Africa

Module 1.2: Wireline Logging Principles

Logging tool physics and measurement principles

Resistivity tools: laterolog, induction, array resistivity

Porosity tools: density, neutron, sonic, NMR

Gamma ray and spectral gamma ray logging

Spontaneous potential (SP) and caliper logs

Temperature and pressure measurement tools

Dipmeter and formation imaging logs

Logging tool limitations and quality control

Module 1.3: Log Interpretation Fundamentals

Quick-look interpretation techniques

Shale volume estimation methods

Porosity determination from multiple logs

Water saturation calculation: Archie equation

Dual water model for shaly sands

Permeability estimation from logs

Net pay determination criteria

Hydrocarbon typing: oil vs. gas identification

Afternoon Session: Advanced Formation Evaluation

Module 1.4: Logging While Drilling (LWD) and MWD

LWD/MWD technology overview

Real-time formation evaluation capabilities

Gamma ray, resistivity, and density while drilling

Azimuthal measurements and geosteering

Formation pressure while drilling

Integration with directional drilling operations

LWD advantages in challenging environments

Horizontal well geosteering in Saudi tight reservoirs

Module 1.5: Advanced Petrophysical Analysis

Nuclear magnetic resonance (NMR) logging applications

Fluid typing and movable hydrocarbon estimation

Permeability from NMR: free fluid index, bound fluid

Formation imaging interpretation

Dip analysis and structural characterization

Fracture identification and quantification

Thin-bed analysis and laminated reservoirs

Carbonate reservoir evaluation in GCC fields

Day 2: Core Analysis and Reservoir Testing

Morning Session: Core Analysis Techniques

Module 2.1: Coring Operations and Core Handling

Coring methods: conventional, sidewall, oriented coring

Pressure coring for fluid retention

Core preservation and handling procedures

Core gamma ray and CT scanning

Core-log integration and depth matching

Representative sampling strategies

Core analysis planning and objectives

Coring in high-angle and horizontal wells

Module 2.2: Laboratory Core Analysis

Routine core analysis (RCA): porosity, permeability, saturation

Grain density and lithology determination

Special core analysis (SCAL) overview

Relative permeability measurements

Capillary pressure curves and applications

Wettability assessment and implications

Rock mechanics and geomechanical testing

Core analysis integration with petrophysics

Afternoon Session: Well Testing and Pressure Analysis

Module 2.3: Drill Stem Testing (DST)

DST objectives and planning

DST tool string configuration

Test procedure: flow and buildup periods

Surface equipment and safety systems

Fluid sampling techniques and quality

Pressure analysis and interpretation

Flow rate measurement and well deliverability

DST in HPHT and sour gas environments

Module 2.4: Formation Pressure Testing

Wireline formation testing tools: MDT, RFT

Pretesting and mobility measurement

Pressure gradient analysis and fluid contacts

Permeability estimation from pressure tests

Fluid sampling with wireline tools

Formation testing in horizontal wells

Pressure testing challenges in tight formations

Integration with reservoir characterization

Day 3: Well Completion Design and Operations

Morning Session: Completion Fundamentals

Module 3.1: Completion Types and Selection

Openhole completions: advantages and limitations

Cased and perforated completions

Liner completions and expandable systems

Gravel pack completions for sand control

Slotted liner and pre-packed screens

Completion selection criteria

Economic considerations and optimization

Regional completion practices in Middle East and Africa

Module 3.2: Perforating Technology

Perforating gun systems: wireline, tubing-conveyed, through-tubing

Shaped charge design and performance

Perforation parameters: shot density, phasing, penetration

Underbalanced vs. overbalanced perforating

Extreme overbalance perforating techniques

Perforation damage and cleanup

Perforating strategy for horizontal wells

Oriented perforating in fractured reservoirs

Afternoon Session: Sand Control and Production Enhancement

Module 3.3: Sand Control Techniques

Sand production mechanisms and prediction

Sanding criteria and risk assessment

Gravel pack design: conventional and high-rate

Frac-and-pack completions

Expandable sand screens technology

Standalone screen completions

Chemical consolidation methods

Sand control in Oman weak sandstone formations

Module 3.4: Well Stimulation Methods

Acidizing Treatments:

Matrix acidizing fundamentals

Acid types: HCl, HF, organic acids

Carbonate acidizing: wormhole creation

Sandstone acidizing: clay stabilization

Acid placement techniques

Diversion methods: mechanical, chemical

Post-acidizing evaluation

Hydraulic Fracturing:

Fracture mechanics and geometry

Proppant selection and placement

Fracture design optimization

Horizontal well multi-stage fracturing

Unconventional reservoir stimulation

Saudi Arabia’s tight gas fracturing programs

Environmental considerations and regulations

Day 4: Advanced Completions and Intelligent Systems

Morning Session: Horizontal and Complex Well Completions

Module 4.1: Horizontal Well Completions

Openhole horizontal completions

Cased-hole horizontal completions

Multi-stage fracturing systems: plug-and-perf, sliding sleeves

Cemented vs. uncemented completions

Liner hanger systems and accessories

Swellable packer technology

Extended reach drilling (ERD) completions

Maximum reservoir contact (MRC) well completions in Saudi fields

Module 4.2: Multilateral and Multi-zone Completions

Multilateral well classification (TAML levels 1-6)

Junction design and integrity

Multi-zone completion strategies

Selective completion techniques

Zone isolation: packers, bridge plugs, valves

Commingled production considerations

Dual completion systems

Multi-lateral wells in Oman mature fields

Afternoon Session: Intelligent Well Technology

Module 4.3: Intelligent Completion Systems

Intelligent well objectives and benefits

Downhole monitoring sensors: pressure, temperature, flow

Inflow control devices (ICD): passive flow control

Inflow control valves (ICV): active flow control

Interval control valves and sliding sleeves

Downhole gauges: permanent monitoring systems

Fiber optic distributed sensing: DTS, DAS

Real-time reservoir management applications

Module 4.4: Completion Optimization

Production optimization through intelligent systems

Water and gas conformance control

Reservoir surveillance using downhole data

Remote well control and automation

Integration with digital oilfield platforms

Economic justification of intelligent completions

Case studies: ADNOC intelligent field implementations

Lessons learned from GCC intelligent well projects

Day 5: Well Intervention and Integrity Management

Morning Session: Workover and Intervention Operations

Module 5.1: Well Intervention Techniques

Workover vs. intervention definitions

Intervention objectives: production enhancement, remedial, abandonment

Rig-based workover operations

Coiled tubing interventions

Wireline operations: slickline and e