Welding Process, Inspection and Metallurgy

$5500.00

Welding Process, Inspection and Metallurgy: 5-Day Advanced Professional Training Course

Course Overview

This comprehensive 5-day advanced welding course integrates welding process engineering, metallurgical principles, and weld inspection methodologies designed for professionals across Saudi Arabia (KSA), Oman, UAE, Qatar, Kuwait, Bahrain, and African industrial markets. This program delivers critical expertise in welding metallurgy, non-destructive testing (NDT), quality assurance, and failure analysis essential for oil and gas, petrochemical, power generation, construction, and manufacturing sectors throughout the GCC region and Africa.

Target Audience

Welding inspectors and quality control engineers in KSA and GCC industries

Metallurgical technicians working in Oman manufacturing and African mining sectors

Welding engineers designing procedures for Saudi Aramco and ADNOC projects

NDT technicians requiring advanced inspection certification across Middle East

Maintenance supervisors overseeing critical infrastructure in GCC countries

Project managers responsible for fabrication quality in African construction

Day 1: Welding Metallurgy Fundamentals and Material Science

Morning Session: Material Science for Welding Applications

Atomic structure and bonding mechanisms in metallic materials

Crystal structures: BCC, FCC, HCP and their impact on weldability

Phase diagrams interpretation: Iron-Carbon equilibrium diagram analysis

Microstructural components: ferrite, austenite, pearlite, martensite, bainite

Heat treatment fundamentals: annealing, normalizing, quenching, tempering

Mechanical properties: tensile strength, hardness, toughness, ductility testing

Material specifications common in GCC projects: ASTM, ASME, API standards

Afternoon Session: Weldability and Heat-Affected Zone (HAZ)

Weldability assessment criteria for carbon steels, alloy steels, stainless steels

Heat-affected zone (HAZ) characteristics and microstructural transformations

Welding thermal cycles and cooling rate calculations

Grain growth mechanisms and coarsening effects on mechanical properties

Preheating and post-weld heat treatment (PWHT) requirements

Carbon equivalent formulas (CE, Pcm) for crack susceptibility prediction

Hydrogen-induced cracking prevention in high-strength steel applications

Material selection for Saudi petrochemical plants and African pipeline projects

Learning Outcomes: Deep understanding of metallurgical principles governing weld joint performance in critical GCC infrastructure and African industrial applications.

Day 2: Advanced Welding Processes and Process Variables

Morning Session: Arc Welding Process Metallurgy

Submerged Arc Welding (SAW): high-deposition applications in pressure vessel fabrication

Shielded Metal Arc Welding (SMAW) metallurgy: electrode coating effects

Gas Metal Arc Welding (GMAW): metal transfer modes and microstructure control

Gas Tungsten Arc Welding (GTAW): precision welding for aerospace and nuclear applications

Flux-Cored Arc Welding (FCAW): slag-metal reactions and alloy transfer

Welding consumable selection per AWS A5 specifications and Saudi Aramco requirements

Shielding gas metallurgy: oxidation prevention, nitrogen pickup, porosity control

Afternoon Session: Specialized Welding Processes

Resistance Welding (RSW): automotive and manufacturing applications across GCC

Friction Stir Welding (FSW): solid-state joining for aluminum in African industries

Laser Beam Welding (LBW): high-precision applications in Oman manufacturing

Electron Beam Welding (EBW): vacuum welding for critical aerospace components

Plasma Arc Welding (PAW): keyhole and melt-in modes for specialized applications

Welding process selection matrices for different materials and service conditions

Economic analysis of welding process selection for African infrastructure projects

Process parameters optimization: current, voltage, travel speed, heat input control

Learning Outcomes: Comprehensive knowledge of welding process metallurgy and optimal process selection for diverse GCC and African industrial requirements.

Day 3: Welding Defects, Discontinuities and Failure Analysis

Morning Session: Weld Discontinuities Classification

Planar vs volumetric defects: criticality assessment for structural integrity

Porosity types: gas porosity, wormholes, cluster porosity, root causes

Incomplete fusion and penetration: joint design and procedure issues

Cracks classification: hot cracks (solidification, liquation) vs cold cracks (hydrogen)

Lamellar tearing in thick plate T-joints for offshore structures

Undercut, overlap, and slag inclusions: formation mechanisms and prevention

Spatter and arc strike damage: acceptance criteria per ASME Section VIII

Reheat cracking in Cr-Mo steels used in GCC power generation plants

Afternoon Session: Metallurgical Failure Analysis

Fracture mechanics fundamentals: brittle vs ductile failure modes

Stress corrosion cracking (SCC) in Arabian Gulf marine environments

Fatigue failure analysis: cyclic loading in offshore platforms and African bridges

Corrosion mechanisms: uniform, pitting, crevice, galvanic corrosion in welds

High-temperature failures: creep, oxidation in refinery equipment

Case studies: weld failures in Saudi industrial facilities and African mining operations

Root cause analysis methodology and corrective action implementation

Metallographic examination techniques: specimen preparation, etching, microscopy

Learning Outcomes: Expert-level defect recognition and failure analysis capabilities essential for quality assurance in high-stakes GCC and African projects.

Day 4: Non-Destructive Testing and Weld Inspection Methods

Morning Session: Visual and Surface Inspection Techniques

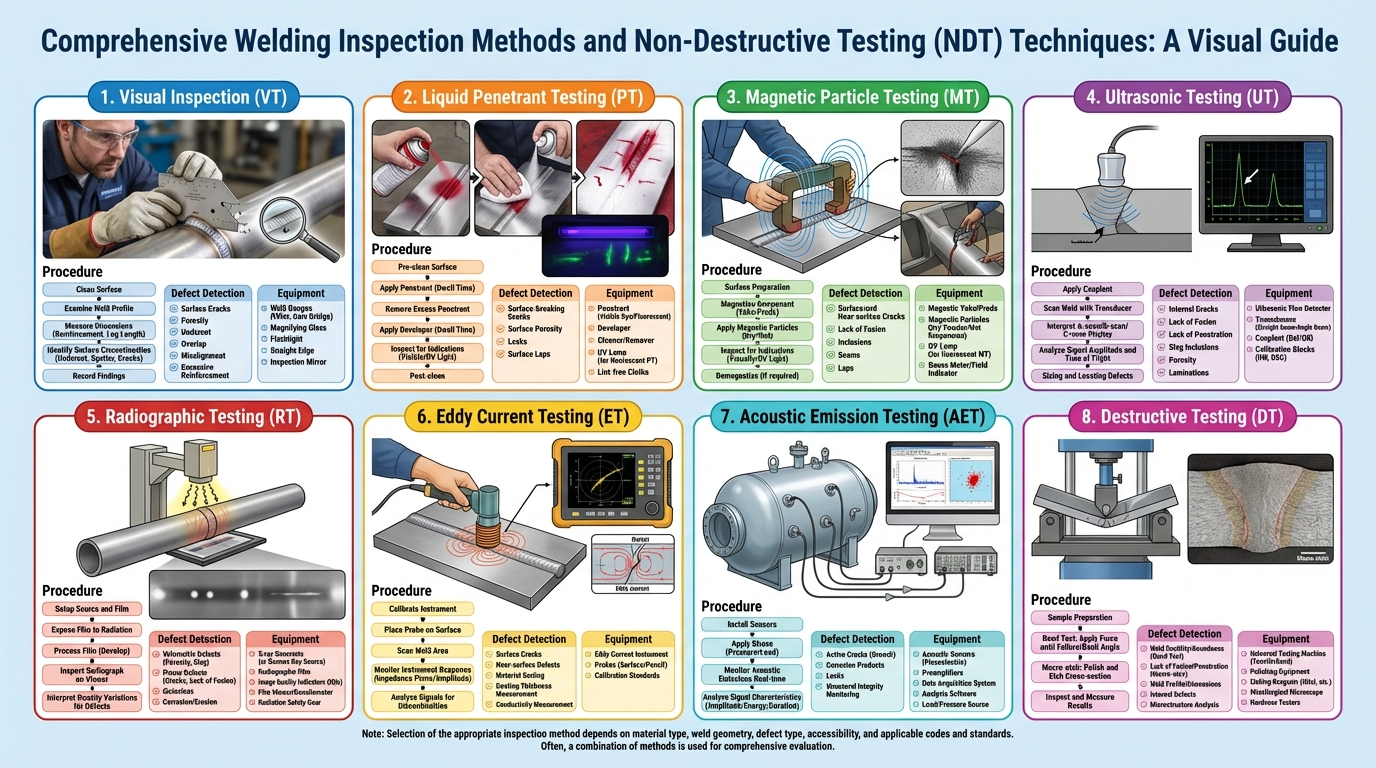

Visual weld inspection (VT): systematic examination per AWS D1.1 and ASME B31.3

Inspection tools: weld gauges, fillet gauges, Hi-Lo gauges, magnifiers

Surface preparation and cleanliness requirements before inspection

Liquid Penetrant Testing (PT/DPT): fluorescent and visible dye methods

Magnetic Particle Testing (MT): wet fluorescent and dry powder techniques

Surface crack detection in carbon steel structures across KSA construction sites

Acceptance standards: workmanship vs fitness-for-service criteria

Documentation requirements for Saudi Aramco contractor approval

Afternoon Session: Volumetric Inspection Methods

Radiographic Testing (RT): X-ray and gamma-ray imaging principles

Film interpretation: porosity, cracks, lack of fusion identification on radiographs

Ultrasonic Testing (UT): pulse-echo technique, A-scan interpretation

Phased Array Ultrasonic Testing (PAUT): advanced inspection for pipeline girth welds

Time-of-Flight Diffraction (TOFD): accurate crack depth sizing

Eddy Current Testing (ECT): heat exchanger tube inspection applications

Inspection frequency and sampling plans per API 570 and API 510

Digital radiography and computed tomography in modern GCC facilities

Learning Outcomes: Comprehensive NDT knowledge enabling certification pathways (ASNT Level II/III, PCN) for high-demand inspection careers in Middle East and Africa.

Day 5: Welding Codes, Standards and Quality Management

Morning Session: International Welding Standards

ASME Boiler and Pressure Vessel Code (BPVC): Section II (Materials), VIII (Pressure Vessels), IX (Qualifications)

AWS Structural Welding Codes: D1.1 (Steel), D1.2 (Aluminum), D1.6 (Stainless)

API Standards: API 1104 (pipelines), API 653 (storage tanks), API 510 (pressure vessels)

ISO 3834: Quality requirements for fusion welding of metallic materials

EN Standards: European compliance for GCC export-oriented manufacturers

Saudi Aramco Engineering Standards (SAES): mandatory requirements for KSA projects

ADNOC specifications: welding requirements for UAE oil and gas sector

African standards harmonization: ARSO guidelines for regional projects

Afternoon Session: Quality Management and Welding Coordination

Welding Procedure Specification (WPS) development and qualification

Procedure Qualification Record (PQR): essential and supplementary variables

Welder Performance Qualification (WPQ): testing and recertification requirements

Welding Procedure Data Sheet (WPDS) for production control

International Welding Engineer (IWE) and International Welding Inspector (IWI) certifications

Quality control plans for African infrastructure megaprojects

Traceability systems: material certificates, welding consumables, welder identification

Pre-qualification programs for Saudi contractor approval

Practical workshop: WPS writing exercise for pressure piping application

Final examination and course certification

Learning Outcomes: Mastery of codes, standards, and quality systems required for compliance in GCC regulatory environments and international African projects.

Course Benefits for GCC and African Professionals

✓ Industry-recognized certification aligned with Saudi Aramco, ADNOC, SABIC requirements

✓ Advanced metallurgical knowledge for materials used in Middle East extreme environments

✓ NDT competency preparation for ASNT, PCN, CSWIP certification exams

✓ Practical failure analysis skills reducing downtime in African mining and GCC petrochemical operations

✓ Career advancement to welding engineer, QC manager, inspection supervisor roles

✓ Bilingual technical training (English/Arabic) for regional accessibility

Investment in Professional Excellence

This advanced welding course addresses the critical skills gap in quality assurance and engineering positions across Saudi Arabia’s Vision 2030 industrial diversification, Oman’s manufacturing expansion, UAE’s aerospace sector, and African infrastructure renaissance. Certified professionals command premium salaries (SAR 8,000-20,000 monthly in KSA) and enjoy exceptional career mobility across oil and gas, power generation, shipbuilding, and construction sectors throughout the Middle East and Africa.

Register now to elevate your expertise and secure leadership positions in the GCC’s booming industrial economy and Africa’s emerging markets!

Keywords: welding inspection course KSA, welding metallurgy training Saudi Arabia, NDT certification Oman, weld inspector training GCC, welding quality control Africa, ASME welding standards, AWS inspection certification, welding engineering course Middle East, metallurgical testing Africa, Saudi Aramco welding inspector, ADNOC quality assurance, pipeline inspection training, pressure vessel welding Gulf, welding failure analysis, CSWIP certification GCC