Upstream Production for Oil and Gas

$5500.00

Upstream Production for Oil and Gas: 5-Day Professional Training Course

Course Overview

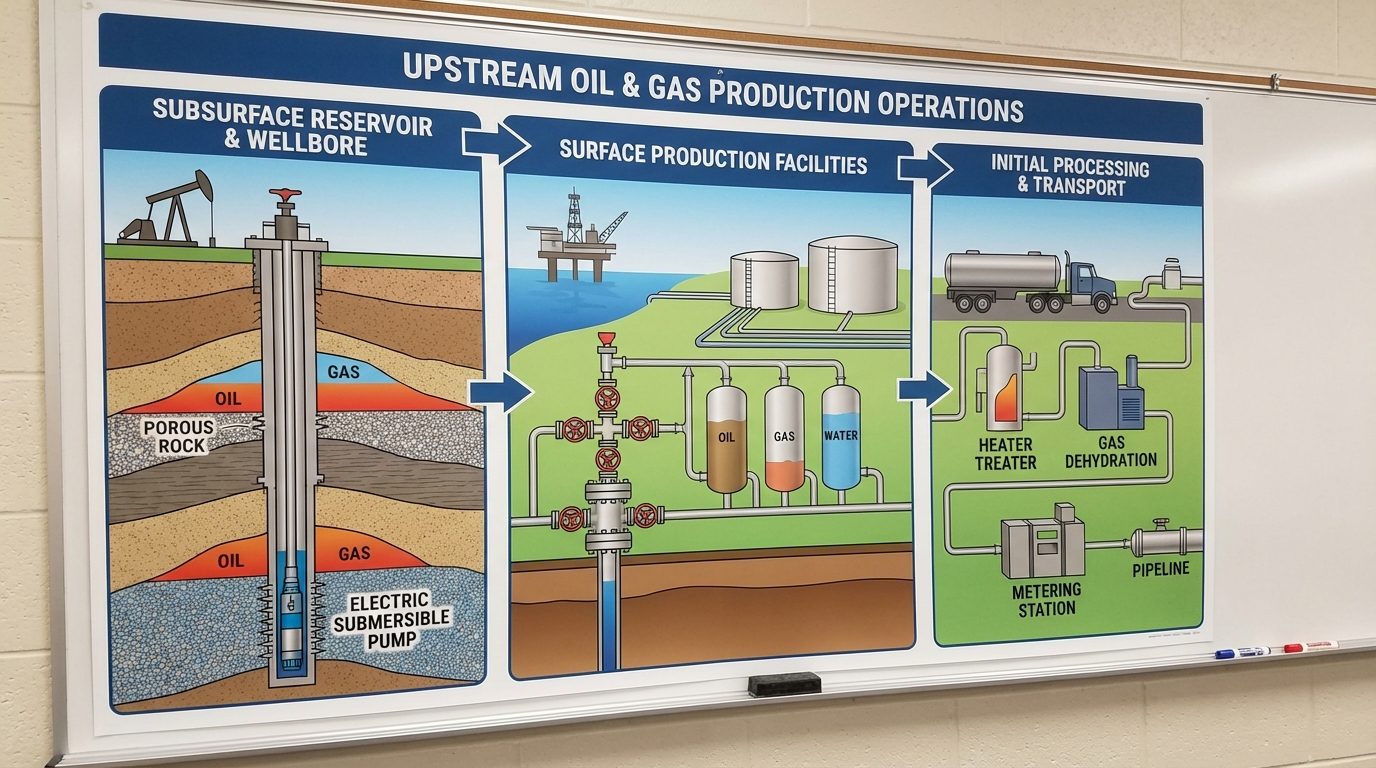

This intensive 5-day training program provides comprehensive knowledge of upstream oil and gas production operations, from reservoir to surface facilities. Specifically designed for professionals in the Kingdom of Saudi Arabia (KSA), Oman, GCC countries, and Africa, this course covers production engineering fundamentals, artificial lift systems, well performance optimization, and facility operations essential for maximizing hydrocarbon recovery.

Who Should Attend

Production engineers and supervisors

Reservoir engineers and petroleum technologists

Operations engineers and field operators

Facility engineers and process technicians

Asset managers and production optimization specialists

Maintenance engineers in upstream operations

Technical professionals from Saudi Aramco, PDO, ADNOC, and African operators

Engineering graduates entering upstream production

Day 1: Fundamentals of Oil and Gas Production

Morning Session: Production System Overview

Module 1.1: Introduction to Upstream Production

Upstream production value chain overview

Well completion and production lifecycle

Primary, secondary, and tertiary recovery methods

Production phases: exploration, development, plateau, and decline

Regional production landscape: KSA’s super-giant fields, Oman’s mature assets, GCC offshore platforms

African production environments: Nigeria, Angola, Egypt, Algeria, and emerging basins

Module 1.2: Reservoir and Well Performance

Reservoir drive mechanisms: solution gas, gas cap, water drive, gravity drainage

Productivity index (PI) and inflow performance relationships (IPR)

Vogel’s correlation and composite IPR curves

Well deliverability and AOF (absolute open flow)

Skin factor and formation damage assessment

Pressure transient analysis fundamentals

Decline curve analysis: exponential, hyperbolic, harmonic

Afternoon Session: Well Completion and Production Systems

Module 1.3: Well Completion Design

Completion types: openhole, cased-hole, liner completions

Perforating strategies and techniques

Sand control methods: gravel pack, frac-pack, screens

Intelligent well completions and downhole monitoring

Multilateral and multi-zone completions

Horizontal well completions in Saudi tight reservoirs

HPHT completions in GCC sour gas fields

Module 1.4: Production Tubing and Wellhead Equipment

Tubing design and selection criteria

Production packers and subsurface safety valves

Wellhead and Christmas tree configurations

Surface safety systems and emergency shutdown devices

Corrosion-resistant alloys for sour service

Material selection for H2S and CO2 environments

API standards and regional regulatory requirements

Day 2: Artificial Lift Systems

Morning Session: Natural Flow and Artificial Lift Selection

Module 2.1: Natural Flow Production

Vertical lift performance and pressure losses

Multiphase flow in tubing: flow regimes and correlations

Gas lift valve spacing and gradient curves

Critical flow rate and liquid loading

Tubing performance relationships (TPR)

Systems analysis and nodal analysis

Well performance optimization

Module 2.2: Artificial Lift Methods Overview

Artificial lift selection criteria and decision matrix

Economic evaluation of lift methods

Regional applications in Middle East and Africa

Lifting challenges in mature fields

High water cut and heavy oil production

Deepwater and subsea lift considerations

Afternoon Session: Artificial Lift Technologies

Module 2.3: Gas Lift Systems

Continuous and intermittent gas lift principles

Gas lift valve design and operation

Gas lift design: valve spacing and mandrel selection

Unloading procedures and troubleshooting

Gas lift optimization in Saudi Arabia and Kuwait fields

Compressed gas availability and allocation

Plunger lift for low-volume wells

Module 2.4: Sucker Rod Pumping and ESP

Sucker rod pumping system components

Pump sizing and design calculations

Rod string design and optimization

Dynamometer analysis and beam pump troubleshooting

Electric submersible pumps (ESP): design and selection

ESP applications in high-volume Oman wells

Variable speed drive control and optimization

ESP monitoring and failure analysis

Module 2.5: Other Artificial Lift Methods

Progressive cavity pumps (PCP) for heavy oil

Hydraulic pumping systems

Jet pumps and their applications

Hybrid lift systems

Artificial lift in African heavy oil fields

Cost-benefit analysis of lift systems

Day 3: Production Operations and Well Testing

Morning Session: Well Testing and Analysis

Module 3.1: Production Testing Fundamentals

Well test objectives and planning

Surface and downhole test equipment

Separator testing and metering systems

Multiphase flow meters and allocation

Test separator principles and sizing

Data acquisition and quality control

Safety considerations during testing operations

Module 3.2: Pressure Transient Testing

Buildup and drawdown tests

Falloff and injection tests

Test design and duration estimation

Wellbore storage and skin effects

Boundary detection and reservoir characterization

Interference and pulse testing

Modern pressure gauge technology

Interpretation software and analysis techniques

Afternoon Session: Production Monitoring and Optimization

Module 3.3: Production Monitoring Systems

Real-time production monitoring and SCADA systems

Downhole sensors and permanent monitoring

Production logging tools: spinner, flowmeter, temperature

Production profiling in multilateral wells

Surveillance techniques for mature fields

Data analytics and machine learning applications

Digital oilfield technology in Saudi Aramco and ADNOC

Module 3.4: Production Optimization Strategies

Field development optimization

Production forecasting and allocation

Choke management and flow optimization

Water cut and gas-oil ratio (GOR) management

Production decline mitigation strategies

Integrated asset modeling

Production enhancement in Oman’s mature fields

Cost per barrel optimization techniques

Day 4: Production Facilities and Surface Processing

Morning Session: Separation and Processing

Module 4.1: Oil and Gas Separation

Phase behavior and separation principles

Two-phase and three-phase separators

Separator sizing and design criteria

Stage separation and pressure optimization

Separator internals and efficiency enhancement

Foam and emulsion handling

Separator performance monitoring

Free water knockout (FWKO) systems

Module 4.2: Crude Oil Processing and Stabilization

Crude oil treating and dehydration

Electrostatic desalting processes

Oil stabilization and vapor recovery

Storage tank design and operations

Crude oil blending and quality control

Export specifications: Arab Light, Arab Heavy, Oman crude

Heating systems and heat exchanger networks

Afternoon Session: Gas Processing and Water Handling

Module 4.3: Gas Processing and Treatment

Natural gas conditioning and sweetening

Gas dehydration: glycol and molecular sieve systems

Hydrocarbon dew point control

Gas compression and export systems

Sulfur recovery and acid gas treatment

Associated gas management in African flare reduction programs

Sales gas specifications for GCC markets

NGL recovery and LPG production

Module 4.4: Produced Water Management

Produced water characteristics and treatment

Oil-water separation technologies

Dissolved gas flotation and hydrocyclones

Water injection systems for pressure maintenance

Water quality requirements for injection

Disposal methods and environmental regulations

Zero discharge initiatives in GCC

Water treatment in African operations

Day 5: Advanced Production Topics and Best Practices

Morning Session: Enhanced Oil Recovery and Special Operations

Module 5.1: Enhanced Oil Recovery (EOR) Methods

Secondary recovery: waterflooding and pressure maintenance

Chemical EOR: polymer, surfactant, alkaline flooding

Thermal EOR: steam injection, SAGD, in-situ combustion

Gas injection: CO2, nitrogen, hydrocarbon gas

Miscible and immiscible displacement

EOR screening criteria and economics

Saudi Arabia’s Shaybah CO2 EOR project

Oman’s polymer flooding initiatives in Marmul field

Module 5.2: Special Production Challenges

Heavy oil production in Kuwait and Venezuela

Sour gas production in Saudi Arabia and UAE

HPHT production operations

Deepwater production systems in West Africa

Sand production control and management

Scale, wax, and asphaltene prevention

Corrosion management and inhibition programs

Production from tight and unconventional reservoirs

Afternoon Session: HSE and Future Technologies

Module 5.3: Production Safety and Environmental Management

Process safety management in production operations

Hazard identification and risk assessment (HAZID/HAZOP)

H2S safety protocols in GCC sour fields

Flare reduction and gas conservation

Environmental regulations: Saudi, Omani, and African standards

Methane emissions monitoring and control

Spill prevention and response procedures

Occupational health in production facilities

Module 5.4: Emerging Technologies and Case Studies

Digital transformation in upstream production

Artificial intelligence for production optimization

Predictive maintenance and IoT sensors

Autonomous operations and robotics

Carbon capture utilization and storage (CCUS)

Geothermal energy integration

Energy transition implications for upstream

Module 5.5: Regional Case Studies Workshop

Saudi Arabia: Ghawar field maximum reservoir contact production

Oman: Mature field rejuvenation strategies at Yibal field

UAE: Offshore ADNOC sour gas production optimization

Kuwait: Heavy oil production enhancement in Greater Burgan

Qatar: North Field gas condensate handling

Nigeria: Deepwater production operations management

Angola: Subsea production systems and FPSO operations

Egypt: Mediterranean gas production and processing

Interactive troubleshooting exercises

Production problem diagnostic workshop

Q&A and knowledge sharing session

Course Learning Outcomes

Participants will gain:

Comprehensive understanding of oil and gas production systems and operations

Practical skills in well performance analysis and optimization

Technical knowledge of artificial lift selection and design

Operational expertise in surface facilities and processing systems

Problem-solving abilities for production challenges

Regional insights specific to KSA, Oman, GCC, and African operations

Safety awareness for HPHT and sour service environments

Economic evaluation skills for production optimization projects

Regional Applications: KSA, Oman, GCC & Africa

Kingdom of Saudi Arabia: Covering super-giant field management, maximum reservoir contact wells, sour gas handling, unconventional tight oil production, and Saudi Aramco’s production excellence standards.

Oman: Focusing on mature field management, enhanced oil recovery implementation, thermal EOR in heavy oil, tight gas production from Khazzan, and PDO operational best practices.

GCC Region: Including ADNOC’s offshore production optimization, Qatar’s gas condensate operations, Kuwait’s heavy oil challenges, Bahrain’s tight oil production, and regional HSE requirements.

Africa: Addressing deepwater production systems, FPSO operations, gas flaring reduction programs, marginal field development, and diverse regulatory environments across Nigeria, Angola, Egypt, Ghana, and Mozambique.

Training Methodology

Expert-led technical lectures with industry examples

Hands-on engineering calculations and simulations

Production optimization software demonstrations

Case study analysis from regional operations

Interactive problem-solving workshops

Group discussions and experience sharing

Video demonstrations of field operations

Comprehensive technical handouts and references

Duration: 5 days (40 training hours)

Delivery: In-person, virtual, or hybrid format

Language: English (Arabic translation available)

Certification: Professional completion certificate recognized by industry

Keywords: upstream production training, oil and gas production course KSA, production engineering Oman, GCC production operations, African petroleum production, artificial lift training, production optimization Middle East, reservoir production management, Saudi Aramco production, PDO operations training, surface facilities course, well testing and analysis