TIG Argon Welding

$5500.00

TIG Argon Welding (GTAW) Professional Training: 5-Day Advanced Certification Course

Course Overview

This comprehensive 5-day TIG welding course provides intensive hands-on training in Gas Tungsten Arc Welding (GTAW) techniques designed for precision applications across Saudi Arabia (KSA), Oman, UAE, Qatar, Kuwait, Bahrain, and African industrial markets. This advanced TIG welding certification program covers tungsten electrode technology, inert gas shielding, pulse welding, all-position techniques, and multi-metal capability essential for aerospace manufacturing, pharmaceutical equipment, food processing, petrochemical piping, power generation, and high-quality fabrication throughout the GCC region and Africa.

Target Audience

Precision welders in Saudi aerospace facilities and GCC pharmaceutical manufacturing

Pipe welders requiring ASME Section IX TIG certification for oil and gas industries

Stainless steel fabricators in food processing and dairy industries across Middle East

Maintenance technicians in power plants, refineries, and chemical facilities

Aluminum welders for automotive, marine, and architectural applications in UAE

Quality-focused professionals seeking premium welding skills for specialized African industries

Day 1: TIG Welding Fundamentals and Equipment Technology

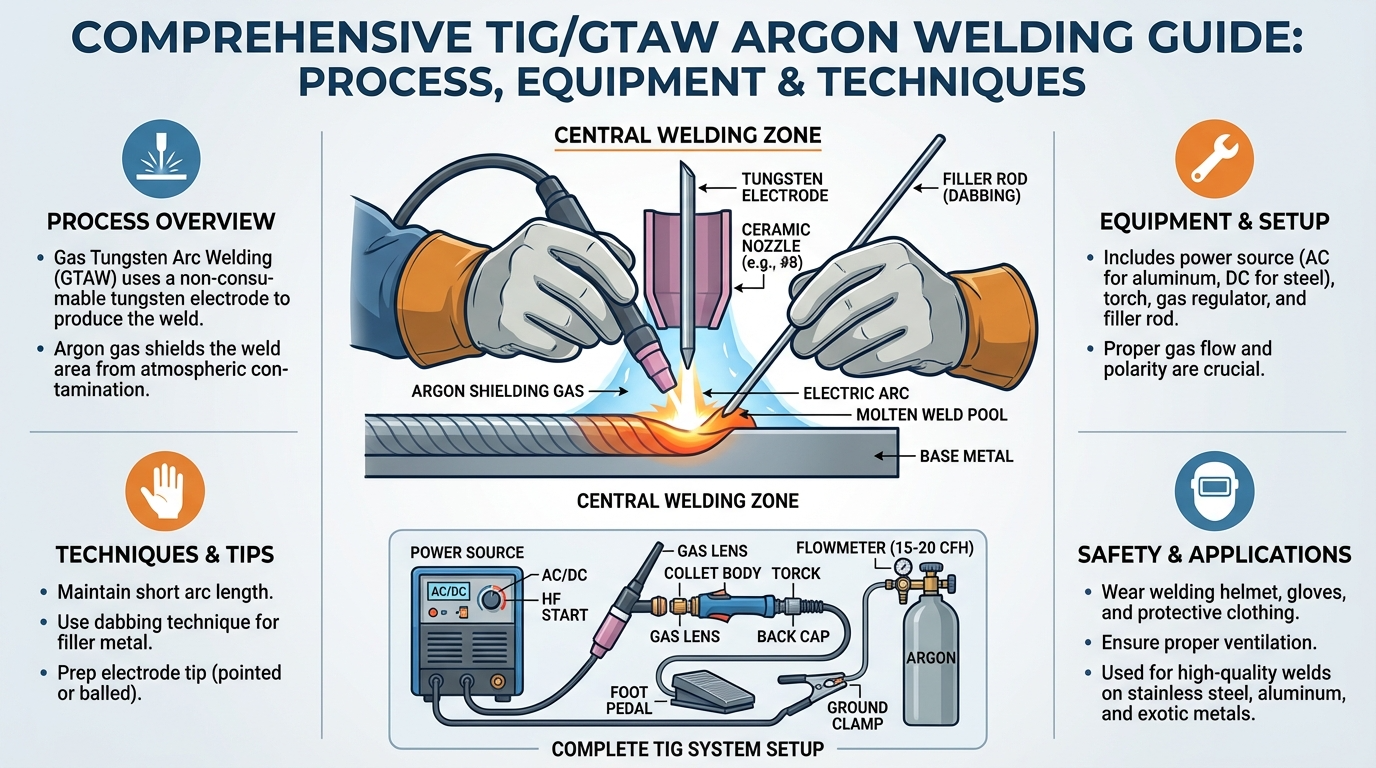

Morning Session: Introduction to GTAW Process

TIG welding principles: non-consumable tungsten electrode, separate filler metal addition

Process advantages: superior weld quality, precise heat control, minimal spatter, clean welds

Applications: stainless steel piping (Saudi Aramco), aluminum aerospace components (UAE)

Material versatility: carbon steel, stainless steel, aluminum, titanium, copper, nickel alloys

Industry requirements: ASME B31.3 process piping, API 650 storage tanks, EEMUA 234 standards

Career opportunities: premium salaries (SAR 8,000-20,000) for certified TIG welders in GCC

GTAW vs other processes: quality comparison, cost-benefit analysis for critical applications

Afternoon Session: TIG Welding Equipment Components

Power source types: transformer machines, inverter technology, AC/DC capabilities

Constant current (CC) characteristics: stable arc, precise amperage control

TIG torch components: torch body, collet, collet body, ceramic cup, gas lens

Air-cooled vs water-cooled torches: amperage capacity (200A vs 500A+) selection

Tungsten electrodes classification: pure, 2% thoriated, 2% ceriated, 2% lanthanated

Electrode grinding techniques: proper taper angles, contamination prevention

Shielding gas systems: Argon purity (99.99%), Helium, Argon-Helium mixtures

Gas flow rates optimization: 10-20 CFH for standard applications, trailing shields

Foot pedal amperage control: remote current adjustment during welding

High-frequency start: contactless arc initiation preventing tungsten contamination

Equipment setup practice: torch assembly, tungsten preparation, gas connection verification

Safety protocols: proper ventilation, fume extraction for stainless steel hexavalent chromium

Learning Outcomes: Complete understanding of precision TIG welding technology and equipment operation essential for high-quality welding positions in GCC aerospace and African specialty manufacturing.

Day 2: DC TIG Welding - Steel and Stainless Steel Applications

Morning Session: DC TIG Welding Fundamentals

DCEN (electrode negative) polarity: standard configuration for steel and stainless

Arc characteristics: concentrated heat, deep penetration, stable arc control

Tungsten selection: 2% ceriated (red), 2% lanthanated (blue) for DC applications

Electrode diameter selection: 1.6mm, 2.4mm, 3.2mm based on amperage requirements

Filler metal selection: ER70S-2 (mild steel), ER308L, ER316L (stainless steel)

Filler rod sizes: 1.6mm, 2.4mm, 3.2mm matching base metal thickness

Cup size selection: #4-#8 ceramic cups for different joint accessibility

Gas lens benefits: laminar gas flow, improved shielding coverage, extended stick-out

Afternoon Session: Carbon Steel and Stainless Steel Flat Position Welding

Joint preparation: edge beveling, root gap, tack welding techniques

Arc starting procedures: high-frequency vs scratch start methods

Torch angle optimization: 70-80° work angle, 10-15° travel angle

Filler metal addition: dabbing technique, maintaining arc length consistency

Puddle control: watching weld pool, adjusting travel speed for penetration

Walking the cup technique: torch stabilization for consistent bead appearance

Stringer beads practice: running continuous beads on mild steel and stainless steel

Butt joint welding (1G): root pass, fill passes, cap pass sequences

Fillet welds (1F): T-joints for stainless steel tanks and pharmaceutical vessels

Stainless steel considerations: lower heat input, preventing carbide precipitation

Corrosion resistance: L-grade stainless (308L, 316L) for food processing equipment

Extensive hands-on practice: 50+ beads developing muscle memory and coordination

Applications: petrochemical piping (SABIC), desalination plants (GCC), dairy equipment (Africa)

Learning Outcomes: Proficiency in DC TIG welding on ferrous metals suitable for precision piping, pharmaceutical manufacturing, and food processing industries across GCC and African markets.

Day 3: AC TIG Welding - Aluminum and Advanced Techniques

Morning Session: AC TIG Welding Fundamentals

Alternating current principles: electrode negative cycle (penetration), positive cycle (cleaning)

Cleaning action importance: oxide layer removal on aluminum and magnesium

Balance control: adjusting EN/EP ratio (typically 70% EN, 30% EP)

Frequency adjustment: higher frequency (100-200Hz) for focused arc, smoother operation

Tungsten selection: pure tungsten (green) or zirconiated (white) for AC welding

Balled tungsten end: proper electrode preparation for AC applications

Power source requirements: AC/DC machines with square wave technology advantages

Afternoon Session: Aluminum TIG Welding Practice

Aluminum alloy classifications: 1xxx, 3xxx, 5xxx, 6xxx series properties and weldability

Filler metal selection: ER4043 (silicon), ER5356 (magnesium) for different applications

Surface preparation critical: stainless steel brush, acetone cleaning, oxide removal

Preheating requirements: 150-200°F for thick sections (>6mm) preventing porosity

Amperage requirements: approximately 1 amp per 0.001" material thickness guideline

Puddle characteristics: recognizing proper fusion, fluidity indicators

Porosity prevention: proper gas coverage, cleaning procedures, avoiding hydrogen sources

Black soot removal: post-weld cleaning for aesthetic appearance

Flat position aluminum welding: butt joints, lap joints, fillet welds practice

Applications: automotive components (Saudi automotive industry), architectural panels (UAE)

Marine applications: aluminum boat fabrication (African fishing industry), yacht building (GCC)

Heat sink effects: aluminum’s high thermal conductivity welding challenges

Hands-on exercises: extensive practice on 3mm-6mm aluminum plates and extrusions

Learning Outcomes: AC TIG welding mastery enabling aluminum fabrication careers in GCC aerospace, automotive, architectural, and African marine industries commanding premium salaries.

Day 4: All-Position TIG Welding and Pipe Welding Fundamentals

Morning Session: Horizontal and Vertical Position TIG Welding

Horizontal groove welds (2G): gravity management, filler metal control techniques

Torch angle adjustment: slightly upward angle preventing sag on vertical surface

Vertical-up TIG welding (3G): keyhole technique for root pass penetration

Stairstepping method: building weld vertically with controlled filler addition

Heat management: preventing burn-through while maintaining proper fusion

Vertical stainless steel applications: pharmaceutical reactor vessels, chemical process tanks

Pulsing amperage benefits: better puddle control in vertical/overhead positions

Practical exercises: 2G and 3G qualification test preparation on stainless steel

Afternoon Session: TIG Pipe Welding Introduction

Orbital position importance: 80% of pipe welding in oil and gas infrastructure

Pipe joint preparation: 37.5° bevel angle, 1/16" root gap, 1/16" land thickness

Root pass critical techniques: open root keyhole method, consistent penetration

Fixed pipe (5G) position: 12 o’clock to 6 o’clock welding progression

Filler metal manipulation: feeding rod consistently into leading edge of puddle

Hot pass requirements: fusing root pass, slight reinforcement building

Fill and cap passes: building proper reinforcement height, smooth transitions

Walking the cup on pipe: stabilization technique for consistent bead profile

ASME Section IX qualification: 6G position test for all-position certification

API 1104 requirements: pipeline construction welding standards for GCC projects

Argon backing gas: preventing root oxidation, ensuring internal weld quality

Hands-on practice: 5G position TIG welding on 2-inch schedule 40 stainless steel pipe

Career applications: Saudi Aramco piping projects, ADNOC refinery maintenance, African gas pipelines

Learning Outcomes: All-position TIG capability and pipe welding fundamentals qualifying for high-demand positions in GCC petrochemical facilities and African energy sector infrastructure.

Day 5: Pulse TIG, Exotic Metals and Certification Testing

Morning Session: Advanced Pulse TIG Welding Technology

Pulse welding benefits: reduced heat input, minimized distortion, improved puddle control

Peak current settings: achieving proper penetration during pulse peak

Background current: maintaining arc stability, reducing overall heat input

Pulse frequency optimization: 0.5-10 pulses per second for different applications

Duty cycle adjustment: percentage of time at peak current vs background

Thin material advantages: 0.5mm-1.5mm stainless steel and aluminum without burn-through

Automotive exhaust systems: precision TIG welding for performance vehicles

Aerospace applications: titanium and Inconel welding for UAE aerospace industry

Practical demonstrations: pulse TIG on thin gauge stainless steel and aluminum

Afternoon Session: Exotic Metals and Qualification Testing

Titanium welding fundamentals: inert gas trailing shields, chamber welding requirements

Nickel alloys: Inconel 625, Hastelloy for chemical processing equipment

Copper and copper alloys: high thermal conductivity challenges, preheating requirements

Dissimilar metal joining: stainless to carbon steel, aluminum to steel techniques

AWS D17.1 aerospace welding specification: stringent requirements for aircraft components

ASME Section IX performance qualification test: test coupon preparation and execution

Bend test procedures: root bend, face bend specimen evaluation

Radiographic examination: understanding RT acceptance criteria for TIG welds

Visual inspection standards: measuring reinforcement, undercut, surface irregularities

Qualification documentation: welder performance qualification (WPQ) record maintenance

Mock certification test: simulated 6G pipe test or 3G plate test execution

Career pathways analysis: welding inspector, welding supervisor, welding engineer progression

Salary benchmarks: experienced TIG welders (SAR 12,000-25,000) in GCC specialty industries

Job placement assistance: connections with aerospace companies, pharmaceutical manufacturers

Entrepreneurship opportunities: mobile TIG welding services for African medical equipment repair

Final practical assessment and industry-recognized TIG welding certification award

Learning Outcomes: Master-level TIG welding competency with exotic metal capabilities and certification qualifying for elite positions in GCC aerospace, pharmaceutical, and African specialized manufacturing sectors.

Course Benefits for GCC and African Markets

✓ 75% hands-on welding time on aerospace-grade equipment matching international standards

✓ Multi-metal proficiency: steel, stainless steel, aluminum, titanium welding capability

✓ ASME Section IX test preparation for immediate employment in GCC oil and gas sector

✓ Pulse TIG technology training for cutting-edge manufacturing applications

✓ Small class sizes (maximum 6 students) ensuring personalized instruction and practice time

✓ Bilingual technical training (English/Arabic) for Middle East professional accessibility

✓ Premium career positioning: access to highest-paid welding positions in GCC markets

✓ International certification: globally recognized credentials for worldwide employment mobility

Investment in Precision Welding Excellence

TIG argon welding represents the pinnacle of welding craftsmanship, commanding the highest salaries and most prestigious positions across Saudi Arabia’s aerospace initiatives, UAE’s advanced manufacturing, Oman’s LNG facilities, and Africa’s pharmaceutical expansion. With Vision 2030 technology localization, GCC industrial diversification, and African manufacturing growth, demand for certified TIG welders continues outpacing supply. Elite employers including Saudi Aerospace Engineering Industries, Stainless Steel Industries (SSI), SABIC, Ma’aden, international pharmaceutical companies, and African medical equipment manufacturers actively recruit skilled TIG welders offering competitive salaries (SAR 10,000-25,000+), international assignments, and excellent career progression.

Enroll today to master the most prestigious welding technology and access premium career opportunities in GCC specialized industries and Africa’s emerging high-tech manufacturing sector!

Keywords: TIG welding course KSA, GTAW training Saudi Arabia, argon welding certification Oman, TIG welder jobs GCC, gas tungsten arc welding UAE, aluminum TIG welding Africa, stainless steel welding course Middle East, pipe TIG welding certification Gulf, aerospace welding training, ASME Section IX TIG qualification, pharmaceutical welding GCC, precision welding course Qatar Kuwait, pulse TIG welding training, Saudi Aramco TIG welder, SABIC welding jobs, titanium welding course, TIG certification Bahrain, advanced welding training Africa