Stress Corrosion Cracking (SCC) in Anhydrous Ammonia Storage Tanks

$5500.00

Stress Corrosion Cracking (SCC) in Anhydrous Ammonia Storage Tanks: 5-Day Specialized Training Course

Course Overview

This intensive 5-day stress corrosion cracking training provides specialized knowledge of SCC phenomena in anhydrous ammonia storage tanks. Designed for integrity engineers, materials specialists, inspection professionals, and facility managers responsible for safe ammonia storage operations.

Target Audience: Integrity engineers, materials engineers, corrosion specialists, NDT inspectors, tank operators, maintenance managers, safety professionals, and regulatory compliance officers.

Course Objectives:

Understand SCC mechanisms in ammonia environments

Identify susceptible materials and conditions

Implement prevention and mitigation strategies

Apply advanced inspection techniques

Develop integrity management programs

Day 1: SCC Fundamentals and Ammonia Environment

Morning Session: Introduction to SCC

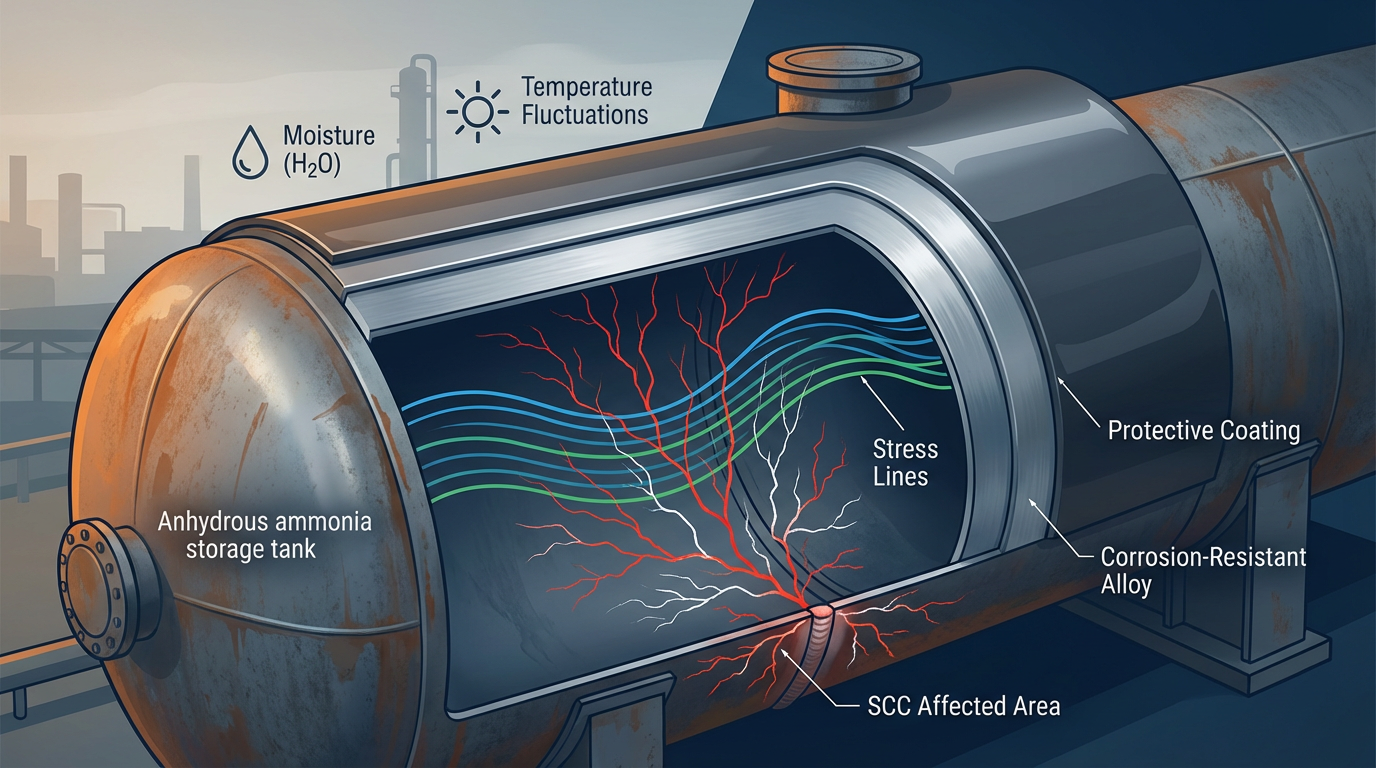

Understanding SCC Phenomena

Foundation of stress corrosion cracking:

SCC Definition:

Environmental cracking requiring three elements

Tensile stress (applied or residual)

Susceptible material (carbon steel)

Corrosive environment (ammonia with contaminants)

Brittle failure without warning

Catastrophic consequences

SCC Characteristics:

Intergranular cracking: grain boundary attack (most common)

Transgranular cracking: through grain structure

Crack branching patterns

Rapid propagation rates

Surface-breaking versus subsurface cracks

Historical Context:

Major ammonia tank failures worldwide

Greensburg, Kansas incident (2001)

Industry lessons learned

Cost impact: property damage, fatalities, evacuations

Evolution of codes and standards

Afternoon Session: Ammonia Storage Systems

Tank Design and Operations

Understanding ammonia storage infrastructure:

Storage Tank Types:

Refrigerated atmospheric storage (-33°C)

Pressurized storage (ambient, 8-10 bar)

Semi-refrigerated systems

Typical capacities: 50 to 50,000+ tonnes

ASME Section VIII and API 620 design

Materials and Construction:

Carbon steel: SA-516 Grade 70, SA-537

Material specifications and properties

Weld procedures and quality

Post-weld heat treatment (PWHT)

Fabrication standards

Critical Components:

Shell plates and welds

Nozzles and penetrations

Heat-affected zones (HAZ): highest SCC risk

Attachment welds

Support structures

Operating Conditions:

Normal pressures and temperatures

Cyclic loading effects

Ammonia purity requirements

Filling and withdrawal procedures

Seasonal variations

Day 2: SCC Mechanism and Susceptibility

Morning Session: SCC Chemistry

How SCC Occurs

Detailed SCC mechanisms:

Chemical Requirements:

Anhydrous ammonia: normally non-corrosive

Contamination essential: water, oxygen, CO₂

Ammonium carbonate formation

Water content thresholds (>0.2% promotes SCC)

Air ingress pathways

Carbon dioxide sources

Electrochemical Process:

Anodic dissolution at crack tips

Cathodic reactions supporting propagation

Film rupture and repassivation

Localized pH changes

Crack chemistry versus bulk environment

Stress Requirements:

Tensile stress necessity

Residual stresses from welding: primary concern

Applied stresses from pressure

Thermal stresses

Threshold levels (>50% yield strength)

Afternoon Session: Susceptibility Factors

High-Risk Conditions

Identifying susceptibility factors:

Material Factors:

Carbon steel susceptibility

HAZ: 10-100x higher risk

Microstructure effects

Hardness correlation (>200 HB increases risk)

Cold-worked areas

Welding-Related:

Weld residual stresses

HAZ microstructural changes

PWHT effectiveness

Weld repair areas

Multiple thermal cycles

Environmental Factors:

Water ingress pathways

Air leakage mechanisms

Temperature cycling and condensation

Tank breathing

Ammonia feedstock impurities

Operational Factors:

Cyclic pressure loading

Rapid filling thermal shock

Inadequate vapor space purging

Maintenance introducing contaminants

Storage duration effects

Day 3: Prevention and Mitigation Strategies

Morning Session: Design Prevention

Preventing SCC Through Design

Implementing prevention strategies:

Material Selection:

Proper carbon steel grades

Hardness limitations: <200 HB maximum

Fine-grained normalized steels

Material certification

Impact-tested materials

Design Considerations:

Stress concentration minimization

Smooth contours and radii

Avoiding dead-legs

Proper drainage

Structural attachment design

Fabrication Best Practices:

Qualified welding procedures (WPS/PQR)

Controlled heat input

PWHT: critical for stress relief

Temperature: 595-650°C (1100-1200°F)

Soaking time based on thickness

Hardness verification (<200 HB)

PWHT Requirements:

ASME Section VIII requirements

Thickness thresholds

Local versus furnace PWHT

Temperature monitoring

Documentation requirements

Afternoon Session: Operational Prevention

Maintaining SCC-Free Conditions

Implementing operational controls:

Ammonia Quality Control:

Purity specifications: >99.5%

Water content limits: <0.2% (2000 ppm)

Oxygen and CO₂ monitoring

Regular sampling and analysis

Source quality verification

Vapor Space Management:

Nitrogen blanketing systems

Preventing air ingress

Relief valve maintenance

Breathing losses minimization

Purging procedures

Operating Procedures:

Controlled filling rates

Temperature management

Pressure cycling minimization

Avoiding thermal shock

Seasonal adjustments

Maintenance Practices:

Nitrogen purging before opening

Moisture exclusion

Proper closure and leak testing

Documentation

Training requirements

Day 4: Inspection and Detection Techniques

Morning Session: NDT Methods

Detecting SCC

Mastering inspection techniques:

Visual Inspection:

External and internal procedures

Crack appearance characteristics

Suspect areas: welds, HAZ, attachments

Documentation and photography

Liquid Penetrant Testing (PT):

Surface crack detection

Application procedures

Developer inspection

ASME Section V acceptance

Limitations: surface-breaking only

Magnetic Particle Testing (MT):

Ferromagnetic inspection

Wet fluorescent methods

Magnetization techniques

Crack sensitivity

Demagnetization

Ultrasonic Testing (UT):

Volumetric crack detection

Shear wave techniques

TOFD and PAUT: advanced methods

Crack sizing

Operator qualification

Afternoon Session: Advanced Techniques

Modern Detection Methods

Applying advanced techniques:

Acoustic Emission (AE):

Real-time crack growth monitoring

Active cracking detection

Sensor placement strategies

Source location

Proof testing

Electromagnetic Inspection:

Eddy current principles

Pulsed eddy current (PEC)

ACFM technology

Through-wall detection

Radiographic Testing:

X-ray and gamma-ray inspection

Digital radiography

Weld quality verification

Radiation safety

Inspection Planning:

Risk-based inspection (RBI)

API 580/581 application

Critical location identification

Inspection frequency

Access requirements

Day 5: Management and Regulatory Compliance

Morning Session: Fitness-for-Service

Evaluating Cracked Tanks

Understanding engineering assessment:

Crack Characterization:

Length, depth, and orientation

Crack growth rate estimation

Remaining life calculations

Criticality assessment

API 579 Fitness-for-Service:

Assessment levels: 1, 2, 3

Crack-like flaw evaluation

Fracture mechanics principles

Stress intensity calculations

Critical crack size

Operating restrictions

Repair Options:

Weld repair procedures

Crack grinding and blending

Composite wrap reinforcement

Pressure deration

Replacement considerations

Afternoon Session: Regulatory Compliance

Standards and Best Practices

Ensuring regulatory compliance:

Regulatory Requirements:

OSHA 29 CFR 1910.111: Anhydrous Ammonia

OSHA PSM 1910.119

EPA Risk Management Program

API 510/653: Inspection Codes

National Board Inspection Code

Industry Standards:

ASME Section VIII

API 620: Storage Tanks

CGA G-2.1: Anhydrous Ammonia

IIAR 2: Refrigeration Equipment

NACE SP0403: SCC Prevention

AWS welding codes

Integrity Management:

Written management plan

Inspection procedures

Qualified inspector requirements

Documentation retention

MOC procedures

Incident investigation

Case Studies:

Real-world SCC failures

Root cause analysis

Corrective actions

Industry lessons

Program Development:

SCC prevention elements

Roles and responsibilities

Performance metrics

Continuous improvement

Audit verification

Course Deliverables

Participants Receive:

Comprehensive SCC technical manual

Inspection procedure templates

API 579 worksheets

NACE SP0403 compliance checklist

Case study compilation

Regulatory reference guide

Professional certificate

Online resources access

Interactive Components:

Crack detection exercises

NDT demonstrations

Fitness-for-service calculations

Failure analysis workshops

Expert Q&A sessions

Why This Training Is Critical

Key Benefits:

Prevent catastrophic failures

Protect lives and community

Avoid environmental disasters

Ensure regulatory compliance

Reduce liability costs

Extend tank service life

Failure Consequences:

Fatalities and injuries

Massive property damage

Environmental contamination

Production shutdowns

Legal liability

Regulatory penalties

ROI:

Proactive inspection << failure costs

Extended asset life

Avoided catastrophic expenses

Reduced insurance premiums

Enhanced safety performance

Keywords: stress corrosion cracking, SCC ammonia tanks, anhydrous ammonia storage, ammonia tank inspection, SCC prevention, carbon steel SCC, PWHT requirements, NDT inspection, API 579, NACE SP0403, ammonia safety, pressure vessel integrity