Smart Manufacturing & Industrial IoT (IIoT)

$800.00

Course Title: Smart Manufacturing & Industrial IoT Implementation

Course Code: ENG-IIOT-2026-008

Start Date: January 15, 2026

End Date: January 19, 2026

Duration: 5 Days (25 Hours)

Mode: Hands-On Lab-Based

Price: 2,900 SAR

Certification: IIoT Implementation Specialist

---

Course Introduction:

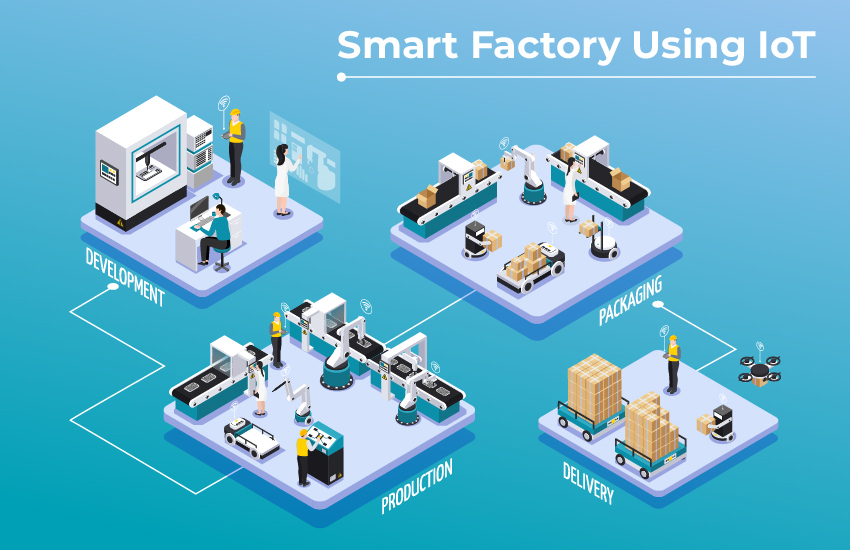

Step into the future of manufacturing with Industry 4.0. Learn to implement

Industrial Internet of Things solutions, predictive maintenance systems,

and smart factory automation. Gain practical experience with sensors,

data analytics, and industrial automation platforms.

Target Audience:

✅ Maintenance Engineers

✅ Manufacturing Managers

✅ Automation Engineers

✅ Plant Operators

✅ Industrial IT Professionals

Skills You'll Acquire:

- Design IIoT architectures for factories

- Implement predictive maintenance systems

- Integrate sensors and monitoring devices

- Analyze industrial data for optimization

- Deploy edge computing solutions

- Ensure industrial cybersecurity

Detailed Training Program:

Day 1: Industry 4.0 & IIoT Fundamentals

- Evolution of industrial revolutions

- Industry 4.0 pillars and technologies

- IIoT architecture and components

- Sensors and actuators overview

- Communication protocols (MQTT, OPC UA, Modbus)

- IIoT vs. Consumer IoT differences

- Case Study: Successful IIoT implementations

- Lab: Setting up basic sensor network

Day 2: Sensor Integration & Data Collection

- Industrial sensor types (temperature, pressure, vibration)

- Wireless sensor networks (WSN)

- Data acquisition systems

- Edge devices and gateways

- Real-time data streaming

- Time-series databases (InfluxDB, TimescaleDB)

- Workshop: Building a sensor monitoring system

Day 3: Predictive Maintenance with AI

- Reactive vs. Preventive vs. Predictive maintenance

- Condition monitoring techniques

- Machine learning for failure prediction

- Anomaly detection algorithms

- Vibration analysis and diagnostics

- Maintenance scheduling optimization

- Project: Develop predictive model for equipment

Day 4: Smart Factory Systems

- Manufacturing Execution Systems (MES)

- Supervisory Control and Data Acquisition (SCADA)

- Programmable Logic Controllers (PLCs)

- Human-Machine Interface (HMI) design

- Digital twins for manufacturing

- Supply chain integration with IIoT

- Lab: Configure SCADA monitoring dashboard

Day 5: Security, Cloud Integration & Future Trends

- Industrial cybersecurity best practices

- Network segmentation for OT/IT

- Cloud platforms for IIoT (AWS IoT, Azure IoT)

- Edge computing and fog computing

- 5G in industrial applications

- AR/VR for maintenance and training

- Blockchain in supply chain

- Final project presentation and certification

Hands-On Labs:

- 15+ practical exercises with real hardware

- Industrial sensor kits provided

- Raspberry Pi and Arduino boards

- PLC programming simulators

- SCADA software (Ignition, Wonderware)

- Cloud platform access

Technologies Covered:

- Sensors: temperature, humidity, pressure, vibration

- Communication: MQTT, CoAP, OPC UA

- Platforms: AWS IoT Core, Azure IoT Hub

- Data: InfluxDB, Grafana, Apache Kafka

- ML: Python, TensorFlow for predictive analytics

- Security: VPN, firewalls, encryption

Course Deliverables:

✅ 300-page technical manual

✅ Hardware sensor kit (to keep)

✅ Software licenses (6 months)

✅ IIoT reference architecture templates

✅ ROI calculation toolkit

✅ Vendor comparison guide

Prerequisites:

- Basic understanding of manufacturing processes

- Familiarity with industrial equipment

- Basic computer and networking knowledge

- No programming required (helpful but not mandatory)

Certification:

- Practical project assessment

- Written exam (50 questions)

- Industry-recognized certificate

- Digital portfolio of completed projects

Instructor:

Eng. Abdullah Rahman, MSc Industrial Engineering - 18 years in

manufacturing automation, led IIoT projects at Aramco and SABIC,

Certified Industry 4.0 Specialist.

Lab Equipment:

Fully equipped lab with industrial-grade sensors, PLCs, and connectivity

devices. Participants will work in teams of 3-4 on real equipment.

Career Impact:

- Average salary increase: 25-30%

- High demand for IIoT specialists in GCC region

- Job placement support provided

Corporate Training:

Custom programs available for manufacturing facilities

Keywords: Industrial IoT training, Industry 4.0 course, predictive

maintenance, smart manufacturing, IIoT certification Saudi Arabia