Introduction to Ammonia Plant Process Units

$5500.00

Introduction to Ammonia Plant Process Units: Complete 5-Day Training Course

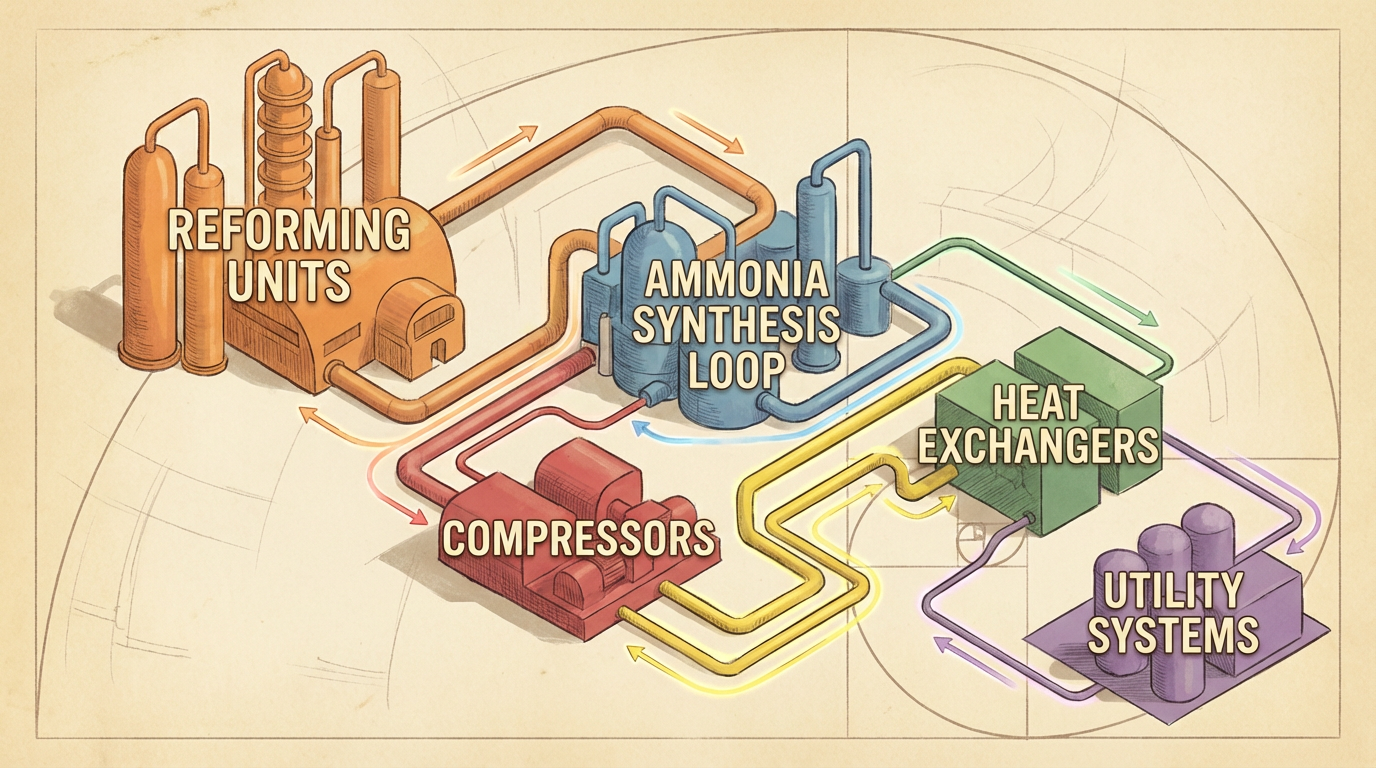

Course Overview

This intensive 5-day ammonia plant training program provides participants with comprehensive knowledge of ammonia production processes, equipment operations, and industry best practices. Designed for chemical engineers, plant operators, maintenance personnel, and industry professionals, this course covers the complete ammonia synthesis process from feedstock preparation to final product storage.

Target Audience: Chemical engineers, process engineers, plant operators, maintenance technicians, production managers, and professionals seeking to understand ammonia manufacturing operations.

Prerequisites: Basic understanding of chemical engineering principles, process flow diagrams, and industrial plant operations.

Day 1: Ammonia Production Fundamentals and Feedstock Preparation

Morning Session: Introduction to Ammonia Industry

Understanding Ammonia Manufacturing

The opening session establishes the foundation for ammonia plant operations, covering the historical development of the Haber-Bosch process and its revolutionary impact on global agriculture and industrial chemistry. Participants explore the current global ammonia market, production capacity statistics, and major manufacturing hubs worldwide.

Key topics include:

Ammonia applications in fertilizer production, refrigeration, chemical synthesis, and industrial processes

Global production statistics and market trends

Environmental considerations and sustainability initiatives in ammonia production

Overview of modern ammonia plant configurations and capacities

Economic factors affecting ammonia manufacturing

Afternoon Session: Feedstock Preparation Systems

Natural Gas Desulfurization Process

This critical first step in ammonia production removes sulfur compounds that would poison downstream catalysts. The session covers:

Hydrodesulfurization (HDS) technology and reactor design

Zinc oxide polishing beds for trace sulfur removal

Sulfur specifications for catalyst protection

Operating parameters: temperature (350-400°C), pressure considerations

Catalyst life management and regeneration strategies

Alternative feedstock options: naphtha, coal, and renewable sources

Process Control and Monitoring

Participants learn about analytical instruments, online sulfur analyzers, and quality control procedures ensuring feedstock purity meets stringent ammonia plant requirements.

Day 2: Primary and Secondary Reforming Operations

Morning Session: Primary Reforming Technology

Steam Methane Reforming (SMR) Process

The primary reformer represents the heart of conventional ammonia plants, where natural gas reacts with steam over nickel catalysts to produce synthesis gas. This comprehensive module covers:

Reformer furnace design: top-fired, side-fired, and terrace wall configurations

Catalyst tube metallurgy and material selection for high-temperature operation

Reforming reactions and thermodynamic equilibrium

Steam-to-carbon ratio optimization (typically 3:1 to 4:1)

Operating conditions: 750-850°C, 25-40 bar pressure

Heat management and thermal efficiency optimization

Burner technology and fuel gas distribution systems

Catalyst Management

Detailed coverage of nickel-based reforming catalysts, including:

Catalyst activation procedures

Carbon formation prevention strategies

Catalyst life expectancy (4-8 years typical)

Performance monitoring and optimization techniques

Afternoon Session: Secondary Reforming and Air Introduction

Secondary Reformer Operations

The secondary reformer completes methane conversion while introducing nitrogen for ammonia synthesis. Training includes:

Autothermal reforming principles

Air compression and preheating systems

Combustion chamber design and refractory materials

Catalyst bed configuration and performance

Temperature control (950-1050°C typical outlet)

Achieving optimal hydrogen-to-nitrogen ratio (3:1 stoichiometric)

Process Integration

Understanding the thermal coupling between primary and secondary reformers, heat recovery systems, and overall energy efficiency optimization strategies.

Day 3: Shift Conversion and CO₂ Removal Systems

Morning Session: Water-Gas Shift Reaction

High-Temperature Shift (HTS) and Low-Temperature Shift (LTS)

These critical process units convert carbon monoxide to carbon dioxide and additional hydrogen through the water-gas shift reaction. Comprehensive coverage includes:

High-Temperature Shift Converter:

Iron-chromium oxide catalysts

Operating temperature range: 350-450°C

Equilibrium limitations and conversion efficiency

Heat recovery and steam generation

Catalyst deactivation mechanisms and prevention

Low-Temperature Shift Converter:

Copper-zinc oxide catalysts

Operating temperature: 190-235°C

Achieving low CO slip (0.2-0.3% typical)

Temperature control criticality for catalyst protection

Pyrophoric catalyst handling procedures

Afternoon Session: Carbon Dioxide Removal Technologies

CO₂ Absorption and Stripping

Removing carbon dioxide to parts-per-million levels protects ammonia synthesis catalysts. Training covers multiple technologies:

Chemical Absorption Processes:

Benfield process (hot potassium carbonate)

Amine-based systems (MEA, DEA, MDEA)

Absorber and stripper column design

Solution circulation rates and regeneration energy

Corrosion management and inhibitor programs

Physical Absorption Alternatives:

Pressure swing adsorption (PSA) technology

Membrane separation systems

Cryogenic separation methods

Comparative economics and efficiency analysis

Day 4: Gas Purification and Ammonia Synthesis

Morning Session: Methanation and Final Purification

Trace CO and CO₂ Removal

The methanation reactor provides final purification, converting residual carbon oxides to methane over nickel catalysts:

Methanation reaction chemistry and thermodynamics

Catalyst specifications and operating conditions (250-350°C)

Achieving synthesis gas purity requirements (<10 ppm CO+CO₂)

Temperature control and exotherm management

Catalyst poisoning prevention

Synthesis Gas Compression

Detailed coverage of centrifugal and reciprocating compressor technology for achieving synthesis pressures (150-250 bar typical):

Compressor selection criteria

Inter-stage cooling and condensate removal

Energy efficiency optimization

Mechanical considerations and maintenance requirements

Afternoon Session: Ammonia Synthesis Loop

The Synthesis Reactor - Core of Ammonia Production

This intensive session covers the ammonia converter where nitrogen and hydrogen combine over iron catalysts:

Reactor Technology:

Quench-type converters with multiple catalyst beds

Horizontal converters (Kellogg design)

Radial flow designs for improved efficiency

Internal heat exchanger configurations

Synthesis Conditions and Chemistry:

Operating pressure: 150-300 bar depending on design

Temperature profiles: 350-550°C across catalyst beds

Iron-based catalyst composition and promoters

Conversion per pass: 15-25% typical

Recycle loop operation and purge gas management

Process Optimization:

Synthesis loop efficiency maximization

Inert gas (methane, argon) management

Ammonia separation and refrigeration

Energy recovery from exothermic synthesis reaction

Day 5: Product Recovery, Utilities, and Process Integration

Morning Session: Ammonia Separation and Refrigeration

Product Recovery Systems

Comprehensive training on ammonia separation technologies:

Condensation and refrigeration systems

Multi-stage cooling and phase separation

Ammonia refrigeration cycle design

Flashing and vapor recovery

Product purity specifications (>99.5% typical)

Ammonia Storage and Handling:

Refrigerated storage tank design and safety systems

Pressure vessel specifications

Loading and unloading procedures

Safety considerations and emergency response

Environmental protection measures

Afternoon Session: Utilities and Process Integration

Essential Utility Systems

Understanding support systems critical for ammonia plant operations:

Steam and Power Generation:

High-pressure steam systems and turbine drives

Waste heat recovery boilers

Combined heat and power (CHP) integration

Energy efficiency metrics and optimization

Cooling Water and Process Water:

Cooling tower operations

Boiler feed water treatment

Demineralization systems

Water conservation strategies

Compressed Air and Nitrogen:

Instrument air systems

Plant air requirements

Nitrogen blanketing and inerting applications

Process Safety and Environmental Compliance

Safety Management Systems:

Hazard identification and risk assessment specific to ammonia plants

Process safety management (PSM) requirements

Emergency shutdown systems and interlocks

Ammonia leak detection and mitigation

Personal protective equipment requirements

Environmental Considerations:

Emission control technologies for NOx, CO₂, and ammonia

Wastewater treatment systems

Greenhouse gas reduction strategies

Carbon capture readiness in modern designs

Environmental monitoring and reporting

Course Conclusion: Future Trends and Career Development

Emerging Technologies in Ammonia Production:

Green ammonia production using renewable hydrogen

Electrolysis-based hydrogen generation

Small-scale and modular ammonia plants

Carbon-free ammonia synthesis pathways

Ammonia as energy carrier and fuel

Career Pathways:

Discussion of professional development opportunities in ammonia manufacturing, process engineering roles, and industry certifications.

Course Deliverables and Certification

Participants Receive:

Comprehensive course manual with process flow diagrams and technical specifications

Access to ammonia plant simulation software demonstrations

Case studies from operational facilities worldwide

Certificate of completion recognized by industry associations

Continuing education credits for professional engineers

Assessment Methods:

Daily knowledge checks and interactive quizzes

Practical problem-solving exercises

Group discussions on real-world operational challenges

Final comprehensive examination

Why Choose This Ammonia Plant Training Course?

This industry-leading ammonia production course combines theoretical knowledge with practical operational insights from experienced instructors with decades of ammonia plant experience. The program emphasizes hands-on learning, troubleshooting techniques, and best practices from world-class facilities.

Key Benefits:

Comprehensive coverage of all major ammonia process units

Updated content reflecting latest technology advances

Practical focus on operational excellence and safety

Networking opportunities with industry professionals

Access to technical resources and ongoing support

Registration Information: Contact training coordinators for upcoming course schedules, customized in-plant training options, and group enrollment discounts.

Keywords: ammonia plant training, ammonia production process, Haber-Bosch process, steam reforming, synthesis loop, chemical engineering course, ammonia synthesis catalyst, green ammonia, process optimization, fertilizer production