Integrity Management of Subsea Pipelines

$5500.00

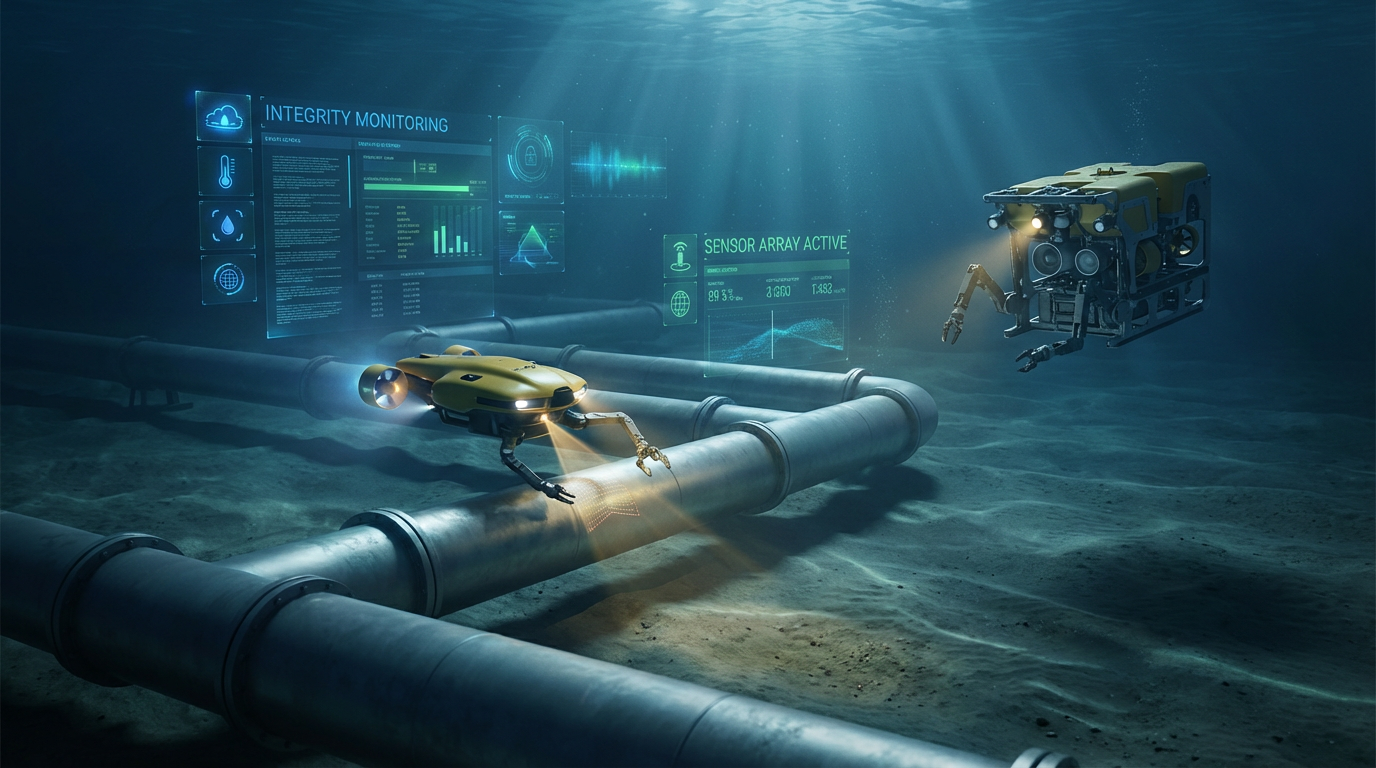

🌊 Integrity Management of Subsea Pipelines: 5-Day Course Outline

Duration: 5 Days | 4 Hours Daily | 20 Total Hours

Level: Intermediate to Advanced

🎯 Course Overview

Comprehensive training on subsea pipeline integrity management covering inspection, corrosion control, risk assessment, and maintenance strategies aligned with API, DNV, and NORSOK standards.

Target Audience: Pipeline integrity engineers, subsea engineers, corrosion specialists, asset managers, operations engineers

Prerequisites: Engineering degree, 2+ years oil & gas experience

📅 DAY 1: Fundamentals & Integrity Threats

Learning Objectives: Understand subsea pipeline systems, identify integrity threats, and comprehend regulatory requirements

Modules:

1.1 Subsea Pipeline Systems

Pipeline types, materials, and coating systems

Design considerations and installation methods

Industry overview and major projects

1.2 Integrity Threats & Failure Mechanisms

External threats (corrosion, third-party damage, free spans)

Internal threats (CO₂/H₂S corrosion, MIC, erosion)

Manufacturing defects and time-dependent degradation

Historical failure analysis

1.3 Regulatory Standards

API 1160, 1163 | ASME B31.4, B31.8

DNV-ST-F101, DNV-RP-F101, DNV-RP-F106

NORSOK Y-002, M-001, M-506

ISO 13623, 16708 | NACE/AMPP standards

1.4 Pipeline Integrity Management System (PIMS)

PIMS structure and components

Data management and KPIs

Management of change procedures

Deliverable: Integrity threat register and PIMS framework

📅 DAY 2: Corrosion Management & Cathodic Protection

Learning Objectives: Master corrosion mechanisms, design CP systems, and implement corrosion control strategies

Modules:

2.1 Corrosion Mechanisms

Electrochemical principles in seawater

CO₂, H₂S, MIC, pitting, crevice corrosion

Environmental factors and corrosion rates

2.2 Internal Corrosion Control

Risk assessment (NORSOK M-506, DNV-RP-F106)

Chemical injection (inhibitors, biocides)

Pigging strategies and monitoring

2.3 External Corrosion & Coatings

Coating types (FBE, 3LPE, concrete)

Selection criteria and inspection

Thermal insulation systems

2.4 Cathodic Protection Design

Sacrificial anode systems (DNV-RP-F103)

ICCP systems and applications

CP monitoring and surveys

Exercise: CP design calculations

2.5 Materials Selection

Carbon steel grades (API 5L, X42-X80)

CRA options (13Cr, duplex, nickel alloys)

Qualification testing

Deliverable: Corrosion management strategy with CP design

📅 DAY 3: Inspection & Condition Assessment

Learning Objectives: Select inspection methods, interpret ILI data, and conduct fitness-for-service assessments

Modules:

3.1 Risk-Based Inspection Strategy

RBI methodology and optimization

Inspection frequency determination

Cost-benefit analysis

3.2 In-Line Inspection (ILI) Technologies

MFL, UT, caliper, IMU tools

Tool selection and capabilities

Pipeline preparation and run requirements

3.3 ILI Data Interpretation

Feature identification and sizing

Metal loss, dents, crack assessment

POI/POD and uncertainty management

Growth rate analysis

Lab: ILI report analysis exercise

3.4 External Inspection

ROV inspections (visual, CP, UT, free spans)

AUV and diver inspections

Survey frequency and documentation

3.5 NDT Methods

UT, RT, MT, PT techniques

Personnel certification requirements

3.6 Fitness-For-Service Assessment

ASME B31G and DNV-RP-F101 methods

Remaining strength calculations

Crack and dent assessment (API 579, BS 7910)

Workshop: FFS calculations

Deliverable: Inspection program and FFS assessment report

📅 DAY 4: Risk Assessment & Operating Windows

Learning Objectives: Conduct risk assessments, define integrity operating windows, and manage emergency response

Modules:

4.1 Risk Assessment Methods

HAZID, HAZOP, FMEA, bow-tie analysis

Qualitative vs. quantitative approaches

Risk matrices and ALARP principle

4.2 Quantitative Risk Assessment

Probability of Failure (PoF) assessment

Consequence of Failure (CoF) analysis

Risk calculation and software tools

Case Study: Pipeline risk assessment

4.3 Risk-Based Integrity Management

RBI optimization and repair prioritization

Direct assessment (ECDA, ICDA, SCCDA)

Dynamic risk updating

4.4 Integrity Operating Windows (IOW)

Operating envelope development

Pressure, temperature, flow, chemical limits

IOW monitoring and excursion management

Workshop: IOW development exercise

4.5 Flow Assurance Integration

Hydrates, wax, scale, sand management

Impact on integrity (erosion, under-deposit corrosion)

Shutdown/startup considerations

4.6 Leak Detection & Emergency Response

CPM, RTTM, acoustic, fiber optic systems

Emergency response plans

Oil spill response procedures

Exercise: Emergency scenario simulation

Deliverable: Risk assessment report, IOW documentation, ERP framework

📅 DAY 5: Maintenance, Repair & Capstone Project

Learning Objectives: Plan maintenance programs, select repair methods, evaluate life extension, and complete comprehensive project

Modules:

5.1 Maintenance Strategies

Preventive, predictive, risk-based maintenance

Pigging programs and procedures

Maintenance optimization

5.2 Repair Technologies

Mechanical clamps, composite wraps

Hot tapping and hyperbaric welding

Repair selection and qualification

Case Study: Major repair operations

5.3 Life Extension & Decommissioning

Remaining life calculations

Re-qualification for changed conditions

Decommissioning options and regulations

Late-life integrity management

5.4 Advanced Technologies

Digital twins and AI/ML applications

Fiber optic sensing (DFOS)

Autonomous inspection (AUVs, robotics)

5.5 Capstone Project Develop complete integrity management program including:

Asset description and threat assessment

Risk and corrosion management strategies

Inspection and maintenance programs

IOW and emergency response plans

KPIs and budget estimates

Team Presentation: 20 minutes + Q&A

5.6 Course Summary

Key takeaways and industry trends

Professional certifications (NACE, API, ASNT)

Continued learning resources

Deliverable: Complete integrity management plan and presentation

🛠️ Standards & Tools Covered

Standards: API 1160/1163/579 | ASME B31G/B31.4/B31.8 | DNV-ST-F101/RP-F101/RP-F103/RP-F106 | NORSOK M-001/M-506/Y-002 | ISO 13623/16708 | BS 7910

Software: PIMS platforms, ILI analysis tools, risk assessment software, FFS calculators, CP design tools

Technologies: MFL/UT/Caliper ILI tools, ROV/AUV systems, NDT equipment, leak detection systems

📚 Course Materials

Technical manual (400+ pages)

Standards reference guide

20+ case studies

Excel calculation tools

Templates and checklists

ILI sample reports

Certificate (40 PDH / 4.0 CEU)

60-day technical support

🎓 Learning Outcomes

✅ Develop comprehensive PIMS programs

✅ Design corrosion control and CP systems

✅ Plan risk-based inspection programs

✅ Interpret ILI data and conduct FFS assessments

✅ Perform quantitative risk assessments

✅ Define integrity operating windows

✅ Select repair and maintenance strategies

✅ Manage emergency response

✅ Evaluate life extension options