Heat exchangers and distillation systems

$5500.00

Heat Exchangers & Distillation Systems: Specialized 5-Day Training Course

Course Overview

This intensive Heat Exchangers and Distillation Systems training program delivers comprehensive technical expertise for engineering professionals across the Kingdom of Saudi Arabia (KSA), Oman, GCC countries (UAE, Qatar, Kuwait, Bahrain), and Africa. The course covers heat exchanger design, thermal analysis, distillation fundamentals, column design, troubleshooting, and performance optimization essential for maximizing efficiency and reliability in refineries, petrochemical plants, gas processing facilities, and chemical industries.

With the Middle East operating over 300 major refineries and petrochemical complexes and Africa’s expanding downstream sector, this training addresses critical competencies for professionals at Saudi Aramco, SABIC, PDO (Petroleum Development Oman), ADNOC, OQ, KNPC, Dangote, Sasol, and other operators managing critical heat transfer and separation equipment accounting for 40-60% of capital investment and significantly impacting energy efficiency, product quality, and operational costs.

Target Audience

Process Engineers in refineries and petrochemical plants across Saudi Arabia, Oman, GCC, Africa

Mechanical Engineers responsible for heat exchanger design and maintenance

Operations Personnel managing distillation columns and heat exchange networks

Design Engineers in EPC companies (Bechtel, Technip, Fluor, Samsung)

Maintenance Engineers troubleshooting heat exchanger and column problems

Project Engineers specifying equipment for new facilities

Performance Engineers optimizing energy efficiency

Technical Managers overseeing separation and heat transfer operations

Day 1: Heat Exchanger Fundamentals & Design

Morning Session: Heat Transfer Principles & Equipment Types

Heat transfer fundamentals: conduction, convection, radiation mechanisms

Fourier’s law, Newton’s law of cooling, Stefan-Boltzmann law

Overall heat transfer coefficient (U): film coefficients, fouling factors, wall resistance

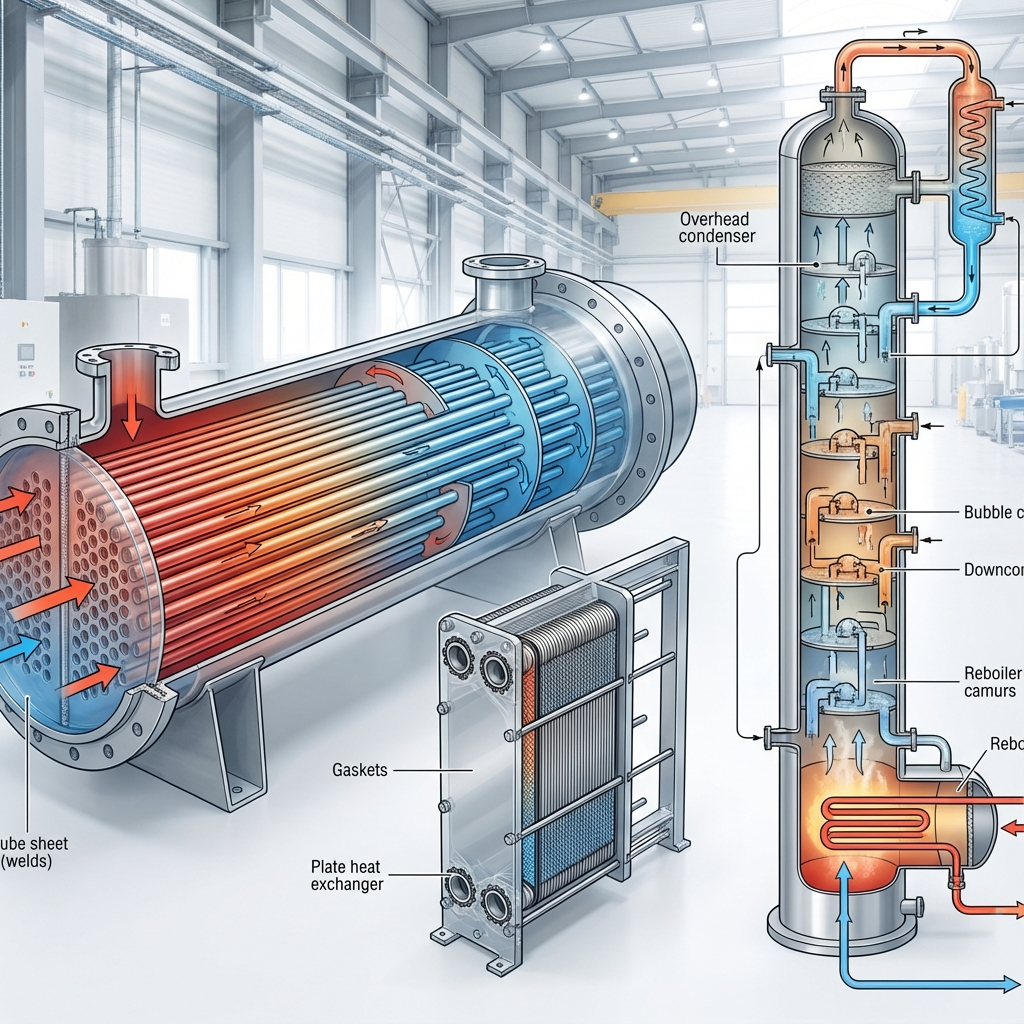

Heat exchanger classification: recuperators vs. regenerators

Shell-and-tube exchangers: fixed tubesheet, floating head, U-tube configurations

TEMA (Tubular Exchanger Manufacturers Association) standards and designations

Plate heat exchangers: gasketed, brazed, welded types for petrochemical applications

Plate-and-frame exchangers: advantages, limitations, maintenance

Air-cooled heat exchangers (ACHE): forced draft, induced draft designs

Critical importance in water-scarce GCC region (Saudi Arabia, UAE, Oman)

Compact heat exchangers: plate-fin, spiral, printed circuit for specialized applications

Double pipe, hairpin exchangers for small duties

Afternoon Session: Shell-and-Tube Design Calculations

TEMA standards: front-end types (A, B, C), shell types (E, F, G, H, J, K, X), rear-end types (L, M, N, P, S, T, U, W)

Thermal design methodology: rating vs. sizing problems

Log Mean Temperature Difference (LMTD): calculation, F-factor correction for multiple passes

ε-NTU (effectiveness-NTU) method for complex configurations

Tube-side design: velocity limits, pressure drop, Reynolds number, friction factor

Tube arrangements: triangular, square, rotated square patterns

Shell-side design: baffle types (segmental, disc-and-doughnut, rod baffle), spacing, cut percentage

Shell-side heat transfer correlations: Kern, Bell-Delaware methods

Pressure drop calculations: tube-side, shell-side, nozzle losses

Fouling considerations: fouling resistances for refinery and petrochemical services

Materials selection: carbon steel, stainless steel, titanium, Monel for corrosive Saudi/Oman environments

Hands-on workshop: Shell-and-tube exchanger design calculations using TEMA standards

Day 2: Air-Cooled Exchangers & Specialized Equipment

Morning Session: Air-Cooled Heat Exchanger Design

ACHE applications: condensers, coolers in refineries, gas plants across GCC

Design considerations for high ambient temperatures (45-55°C in Saudi Arabia, UAE, Oman summers)

API 661 standards: design, construction, installation requirements

Forced vs. induced draft: performance, recirculation, noise considerations

Thermal design: air-side heat transfer, tube-side design, finned tube selection

Fin types: tension-wrapped, L-footed, embedded, extruded for different services

Fan selection: axial fans, motor sizing, variable speed drives

Humidification and fogging systems for hot climate performance enhancement

Noise control: acoustic requirements in industrial areas (Jubail, Yanbu, Sohar, Ruwais)

Winter operation considerations: freeze protection, louvers, variable speed control

Maintenance aspects: tube plugging limits, cleaning access, fan maintenance

Case studies: ACHE optimization at Saudi Aramco refineries, ADNOC facilities

Afternoon Session: Specialized Heat Transfer Equipment

Fired heaters and furnaces: process heaters, reformer furnaces, crude heaters

API 530 design standards, thermal efficiency optimization

Tube metallurgy: high-temperature alloys, creep considerations, thermal cycling

Radiation vs. convection sections: heat distribution, coil design

Reboilers: thermosiphon, kettle, forced circulation types

Reboiler selection criteria and troubleshooting common problems

Condensers: partial, total condensation, multi-component systems

Overhead condenser design for distillation columns in refineries

Vaporizers and evaporators: falling film, rising film, forced circulation

Multi-effect evaporation for desalination, wastewater concentration

Heat exchanger networks (HEN): series, parallel arrangements, temperature cross

Energy integration in Saudi refineries and petrochemical plants

Workshop: Air-cooled exchanger sizing for GCC climate conditions

Day 3: Distillation Fundamentals & Column Design

Morning Session: Distillation Principles & Equilibrium

Distillation overview: separation principle, vapor-liquid equilibrium (VLE)

Phase diagrams: T-x-y, x-y diagrams, relative volatility concept

Raoult’s law and ideal systems: vapor pressure, activity coefficients

Non-ideal systems: azeotropes (minimum, maximum boiling), deviation from ideality

McCabe-Thiele method: graphical stage-by-stage calculation

Operating lines, feed line (q-line), minimum reflux, actual reflux

Column specifications: feed composition, product purities, recovery targets

Degrees of freedom analysis for distillation column design

Shortcut methods: Fenske equation (minimum stages), Underwood equations (minimum reflux)

Gilliland correlation: actual stages from minimum stages and reflux ratio

Multi-component distillation: key components, split specifications

Applications: crude distillation, naphtha splitters, FCC fractionators in Saudi Aramco, ADNOC refineries

Hands-on exercises: McCabe-Thiele construction, shortcut calculations

Afternoon Session: Column Internals & Hydraulics

Tray types: sieve trays, valve trays, bubble cap trays, dual-flow trays

Tray design parameters: hole diameter, hole area, weir height, tray spacing

Tray hydraulics: vapor distribution, liquid flow patterns, entrainment, weeping

Flooding calculations: jet flood, downcomer flood, system limit

Tray efficiency: Murphree efficiency, overall efficiency, factors affecting performance

Packed columns: random packing (Raschig rings, Pall rings, IMTP) vs. structured packing (Mellapak, Flexipac)

Packing selection criteria: pressure drop, capacity, efficiency, cost

Packed column design: HETP (Height Equivalent to Theoretical Plate), flooding correlations

Liquid distributors and redistributors: ensuring uniform liquid distribution

Column diameter sizing: tray columns, packed columns, entrainment limits

Pressure drop: tray pressure drop, packing pressure drop impact on column operation

Regional considerations: high liquid viscosity in heavy crude processing

Day 4: Distillation Column Operations & Troubleshooting

Morning Session: Column Operation & Control

Start-up procedures: pressure testing, initial charge, establishing reflux, bringing to steady state

Normal operations: monitoring key parameters (temperatures, pressures, flows, levels)

Control strategies: temperature control, pressure control, level control, composition control

Reflux ratio control: constant, variable based on feed or product composition

Feed location optimization: impact on separation efficiency and energy consumption

Column pressure control: condenser duty manipulation, inert gas venting

Advanced control: inferential control, feed-forward control, model predictive control (MPC)

Operational limits: flooding, weeping, excessive entrainment, foaming

Product quality control: meeting specifications, analyzing off-spec situations

Turndown operations: minimum rates, part-load performance

Case studies: Crude column operations at Ras Tanura, SATORP fractionators, Sohar operations

Afternoon Session: Troubleshooting & Performance Issues

Common operational problems: poor separation, flooding, capacity limitations, pressure drop issues

Diagnosing tray damage: bent trays, plugged holes, damaged downcomers

Packing problems: channeling, fouling, packing breakage, maldistribution

Vapor-liquid maldistribution: causes, detection, remediation

Foaming: antifoam selection, operational adjustments, design modifications

Corrosion issues: overhead corrosion, bottom corrosion in sour service

Fouling and coking: crude preheat train, vacuum columns, FCC main fractionators

Contamination: feed contamination, tray fouling, salt deposition

Performance testing: tray efficiency testing, gamma scan surveys, temperature profiles

Debottlenecking strategies: increasing capacity without major modifications

Revamp opportunities: tray replacement, packing upgrades, internals modifications

Workshop: Troubleshooting scenarios from GCC refineries and petrochemical plants

Day 5: Advanced Topics & Performance Optimization

Morning Session: Heat Exchanger Fouling & Maintenance

Fouling mechanisms: particulate, crystallization, chemical reaction, corrosion, biological

Fouling in refineries: crude preheat train, FCC slurry exchangers, cooling water systems

Fouling resistance: design values, monitoring actual fouling rates

Mitigation strategies: velocity optimization, temperature control, chemical treatment, materials selection

Chemical cleaning: acid cleaning, alkaline cleaning, solvent cleaning procedures

Mechanical cleaning: tube cleaning methods, high-pressure water jetting

Online cleaning systems: automatic tube cleaning (Taprogge, Hydroball)

Tube inspection techniques: eddy current testing, remote field testing, visual inspection

Tube failure analysis: corrosion, erosion, vibration, thermal fatigue

Repair vs. replacement decisions for aging heat exchangers

Maintenance planning: inspection intervals, cleaning schedules, turnaround activities

Performance monitoring: heat transfer coefficient degradation, fouling curves

Afternoon Session: Energy Optimization & Simulation Tools

Energy efficiency: reducing utility consumption, heat recovery optimization

Pinch analysis application: identifying heat exchange opportunities in crude units

Temperature approach optimization: balancing capital vs. energy costs

Increasing heat recovery in Saudi Aramco refineries, PDO facilities

Distillation optimization: reflux ratio optimization, feed preheating, intermediate reboilers/condensers

Vapor recompression: mechanical, thermal vapor recompression for energy savings

Divided-wall columns: single shell for two-product separation, energy savings

Heat pump integration: using compression for temperature lift

Process simulation tools: Aspen HYSYS, Aspen Plus, PRO/II for rigorous modeling

Exchanger design software: Aspen EDR, HTRI, HTFS widely used in GCC

Rating existing equipment: performance evaluation, remaining capacity assessment

Optimization case studies: Energy savings at YASREF, SATORP heat integration projects

Sustainability considerations: carbon footprint reduction, water conservation in GCC

Future technologies: compact heat exchangers, advanced materials, digitalization

Digital twins: predictive modeling, performance monitoring, maintenance optimization

Final workshop: Integrated optimization project for refinery heat exchange network

Learning Outcomes

Upon completion, participants will be able to:

Design shell-and-tube heat exchangers following TEMA standards for industrial applications

Select and size air-cooled exchangers optimized for high-temperature GCC climates

Design distillation columns: determine stages, reflux ratio, column diameter, internals selection

Troubleshoot operational problems in heat exchangers and distillation columns effectively

Optimize energy efficiency through heat integration and process improvements

Conduct performance evaluations and identify debottlenecking opportunities

Apply simulation software for rigorous thermal and separation modeling

Implement maintenance strategies minimizing fouling and maximizing equipment reliability

Specify equipment for new projects meeting technical and economic requirements

Course Delivery & Certification

Format: Technical lectures, design workshops, calculation exercises, simulation demonstrations, case studies

Software: Introduction to Aspen EDR/HYSYS for heat exchanger and column design

Materials: Comprehensive manual, TEMA standards excerpts, design charts, troubleshooting guides, calculation templates

Certification: Professional certificate recognized by major operators and EPC companies across KSA, Oman, UAE, Qatar, Kuwait, Bahrain, and Africa

Language: English (Arabic translation support available)

CPD Credits: Continuing professional development for process and mechanical engineers

Locations: Riyadh, Dhahran, Jubail, Yanbu (KSA), Muscat, Sohar (Oman), Dubai, Abu Dhabi, Doha, Kuwait City, Lagos, Cairo, Johannesburg

Why This Course is Essential for the Region

GCC refineries and petrochemical plants operate thousands of heat exchangers and distillation columns in extreme conditions (50°C+ ambient temperatures, corrosive crude oils, high-sulfur environments). Saudi Aramco’s refining capacity (2.9 million bpd), ADNOC downstream expansion, Sohar Refinery, Duqm integrated complex, and Dangote Refinery (650,000 bpd) demand engineers skilled in designing, operating, and optimizing this critical equipment.

This training delivers practical expertise incorporating API and TEMA standards, Saudi Aramco SAES specifications, ADNOC design practices, addressing specific regional challenges: water scarcity (ACHE emphasis), heavy crude processing, sour service, fouling in desert environments, and energy efficiency critical for Saudi Vision 2030 and regional sustainability goals.

Master heat transfer. Perfect separation. Optimize performance.