Fundamentals and Best Practices for Urea Plants Operation and Maintenance

$5500.00

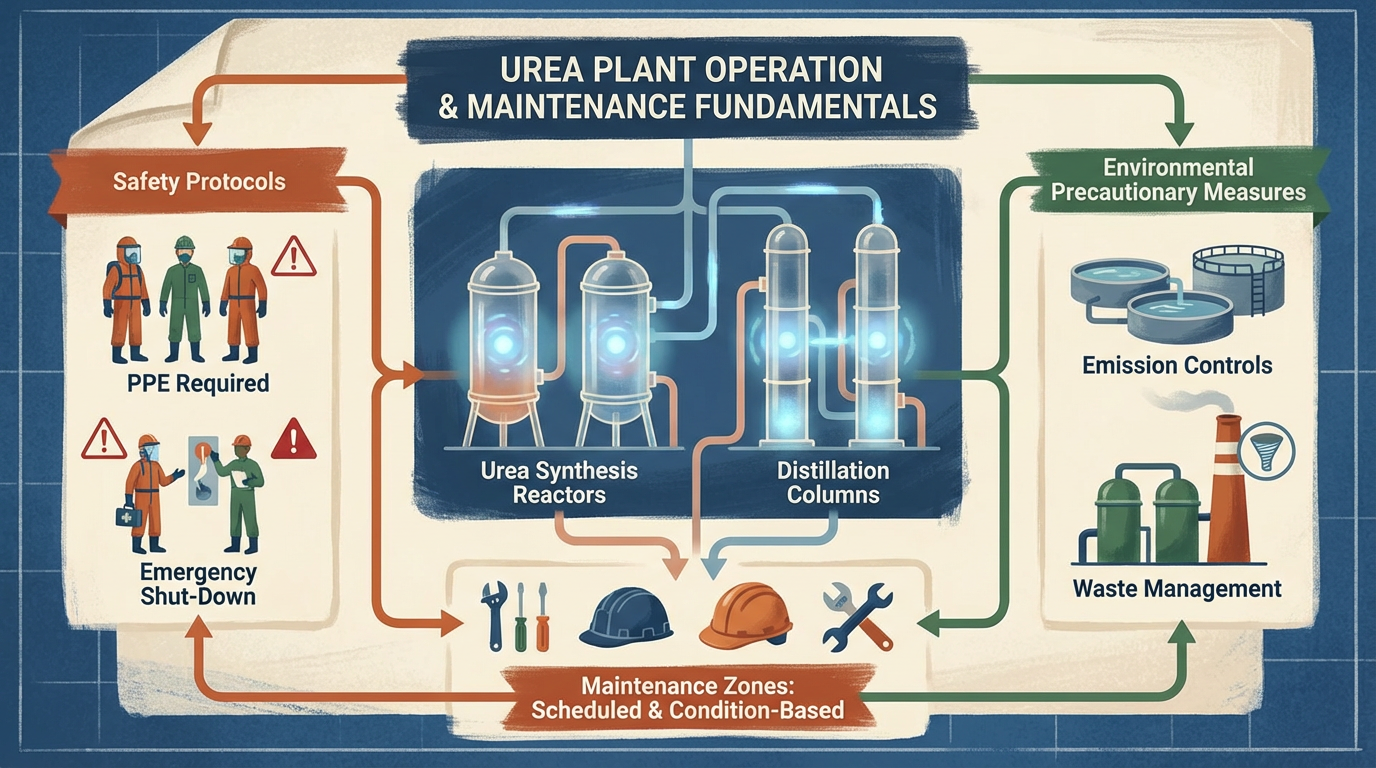

Fundamentals and Best Practices for Urea Plants Operation and Maintenance: 5-Day Professional Training Course

Course Overview

This intensive 5-day urea plant operations and maintenance training provides comprehensive knowledge of urea production processes, equipment optimization, and industry best practices. Designed for plant operators, maintenance engineers, production supervisors, and technical professionals in fertilizer manufacturing.

Target Audience: Plant operators, process engineers, maintenance technicians, production managers, reliability engineers, and professionals working in urea manufacturing facilities.

Course Objectives:

Master urea production processes and chemistry

Implement operational best practices for efficiency

Optimize equipment performance and energy consumption

Develop effective maintenance strategies

Troubleshoot common operational problems

Day 1: Urea Production Fundamentals

Morning Session: Introduction to Urea Manufacturing

Understanding Urea Production

Foundation knowledge of urea synthesis processes:

Industry Overview:

Global urea production and market dynamics

Agricultural and industrial applications (fertilizer, resins, DEF)

Major technologies: Stamicarbon, Saipem, Toyo, Urea Casale

Plant capacities: 1,000 to 4,000+ MTPD

Integration with ammonia plants

Urea Chemistry:

Ammonia and CO₂ reaction mechanisms

Carbamate formation: 2NH₃ + CO₂ → NH₂COONH₄ (exothermic)

Urea formation: NH₂COONH₄ → CO(NH₂)₂ + H₂O (endothermic)

Equilibrium and conversion efficiency

By-product formation: biuret, unreacted materials

Afternoon Session: High-Pressure Synthesis

Urea Reactor Operations

Detailed coverage of synthesis reactor operations:

CO₂ Stripping Process:

High-pressure reactor design (140-160 bar, 180-200°C)

NH₃:CO₂ molar ratio optimization (3.5-4.5:1)

CO₂ stripping technology and principles

Conversion efficiency: 60-65% per pass

Pool reactor versus falling film designs

Alternative Technologies:

Ammonia stripping process (Stamicarbon)

Self-stripping variations

Advanced configurations (IDR, ACES)

Energy efficiency comparisons

Critical Parameters:

Pressure and temperature control

Residence time optimization

Inert gas management

Corrosion inhibitor injection (oxygen, ammonia)

Heat recovery and steam generation

Materials of Construction:

Stainless steel grades: 316L, 25-22-2, Safurex

Titanium for carbamate condensers

Material selection and corrosion mechanisms

Day 2: Recovery and Finishing Operations

Morning Session: Carbamate Recovery

Decomposition and Recovery Systems

Understanding unconverted carbamate recovery:

Medium-Pressure Recovery (MP):

Decomposition at 15-25 bar

HP carbamate condenser operations

Heat integration with synthesis

CO₂ and NH₃ separation

Scrubbing systems for vapor treatment

Low-Pressure Recovery (LP):

Further decomposition at 3-5 bar

LP carbamate condenser operations

Process condensate treatment

Ammonia and CO₂ recovery optimization

Hydrolysis Systems:

Thermal hydrolysis at atmospheric pressure

Operating temperature: 200-230°C

Complete carbamate conversion

Off-gas treatment systems

Afternoon Session: Concentration and Product Finishing

Urea Solution Processing

Mastering concentration and finishing:

Vacuum Concentration:

First and second-stage evaporation (0.3-0.5 bar)

Target concentration: 95-99.7% urea

Vacuum system operations

Biuret formation control (<1.0%)

Energy optimization through multi-effect evaporation

Prilling Operations:

Prilling tower design and operation

Prilling basket and nozzle management

Droplet formation and size control

Counter-current air flow optimization

Product size: 1-3 mm typical

Dust collection and recycling

Granulation Operations:

Fluidized bed and drum granulation

Seed recycle and particle growth

Size classification and screening

Product specifications: 2-4 mm typical

Anti-caking treatments

Superior quality versus prilling

Product Storage:

Bulk storage and caking prevention

Quality control: nitrogen content (46% min), biuret, moisture

Bagging and loading operations

Day 3: Operational Excellence and Optimization

Morning Session: Process Control and Performance

Maximizing Plant Performance

Implementing operational excellence:

Key Performance Indicators:

Production rate and on-stream factor

Conversion efficiency and yield

Energy consumption (steam, power)

Raw material efficiency (NH₃, CO₂)

Product quality metrics

Environmental emissions

Operational Optimization:

NH₃:CO₂ ratio fine-tuning

Temperature and pressure optimization

Inert gas purge optimization

Steam balance and energy recovery

Cooling water efficiency

Condensate recovery maximization

Advanced Process Control:

Model predictive control (MPC)

Cascade and ratio control strategies

Automatic optimization algorithms

Real-time monitoring systems

Quality Control:

Online analyzers and laboratory testing

Nitrogen content verification (46% min)

Biuret and moisture monitoring

Particle size distribution

Physical properties testing

Afternoon Session: Energy Management

Energy Optimization

Reducing energy consumption and costs:

Energy Consumption:

Steam: 0.9-1.2 tons per ton urea

Electricity: 80-120 kWh per ton urea

Cooling water and utilities

Industry benchmarking

Energy Saving Opportunities:

Heat integration and pinch analysis

Waste heat recovery from synthesis

Condensate flash steam recovery

Vacuum system optimization

Motor efficiency and VFDs

Steam trap management

Process condensate reuse

CO₂ Management:

CO₂ sourcing and purification

Optimal compression parameters

CO₂ vent recovery

Carbon footprint reduction

Day 4: Maintenance Excellence and Reliability

Morning Session: Preventive Maintenance

Structured Maintenance Management

Implementing world-class maintenance:

Equipment-Specific Maintenance:

High-pressure equipment inspection (reactors, condensers)

Material degradation monitoring

Pressure vessel inspection programs

Heat exchanger cleaning schedules

Pump and compressor maintenance

Valve testing programs

Corrosion Management:

Passivation procedures for stainless steel

Corrosion inhibitor programs

Monitoring techniques: coupons, probes, inspection

Stress corrosion cracking prevention

Weld inspection and quality

Turnaround Planning:

Major turnaround frequency: 2-3 years

Scope development and critical path

Reactor internals inspection

Stripper and decomposer maintenance

NDT programs and testing

Afternoon Session: Predictive Maintenance

Condition-Based Monitoring

Leveraging predictive technologies:

Vibration Analysis:

Rotating equipment monitoring

Bearing condition assessment

Early fault detection

Optimal intervention timing

Performance Monitoring:

Heat exchanger fouling detection

Pump and compressor efficiency tracking

Pressure drop monitoring

Temperature profile deviations

Reliability-Centered Maintenance:

Critical equipment prioritization

Failure mode effects analysis (FMEA)

Maintenance strategy optimization

Spare parts management

MTBF tracking and root cause analysis

Instrumentation Maintenance:

Calibration programs

Control valve diagnostics

Analyzer maintenance

DCS system health monitoring

Alarm management

Day 5: Troubleshooting and Continuous Improvement

Morning Session: Systematic Troubleshooting

Problem-Solving Methodologies

Expertise in urea plant troubleshooting:

Common Operational Problems:

Low conversion efficiency

High biuret formation

Product quality deviations

Prilling tower air distribution issues

Granulator agglomeration

Vacuum system deterioration

Ammonia emissions

Equipment corrosion

Diagnostic Approaches:

Root cause analysis (5-Why, Fishbone)

Material and energy balance calculations

Process parameter trending

Laboratory testing

Equipment inspection and NDT

Vendor technical support

Case Studies:

Real-world troubleshooting scenarios

Reactor passivation failure

Stripper performance issues

Granulation quality problems

Corrosion-induced failures

Solutions and lessons learned

Afternoon Session: Safety and Digital Innovation

Process Safety Excellence

Implementing comprehensive safety programs:

Hazard Management:

Ammonia toxicity and exposure controls

High-pressure system hazards

Dust explosion prevention

Emergency shutdown systems

Chemical safe handling

Process Safety Management:

Hazard identification and risk assessment

Operating procedures and safe practices

Mechanical integrity programs

Management of change (MOC)

Incident investigation

Environmental Compliance:

Ammonia and dust emission control

Wastewater treatment standards

Process condensate management

Regulatory compliance

Digital Transformation:

Digital twin technology for optimization

AI for predictive maintenance

Machine learning for quality control

Real-time optimization

Mobile applications

Remote monitoring

Continuous Improvement:

Lean manufacturing principles

Six Sigma methodologies

Total productive maintenance (TPM)

Kaizen programs

Operator training simulators

Future Trends:

Green urea with renewable energy

Carbon capture integration

Process intensification

Advanced corrosion-resistant materials

Modular designs

Course Deliverables

Participants Receive:

Comprehensive operations and maintenance manual

Troubleshooting flowcharts

Maintenance templates

KPI tracking tools

Industry benchmark data

Professional certificate of completion

Online resources access

Interactive Learning:

Process simulator demonstrations

Equipment walk-through videos

Group troubleshooting exercises

Maintenance planning workshops

Safety discussions

Expert Q&A sessions

Why This Training Delivers Value

Key Benefits:

Enhanced operational reliability

Improved product quality

Energy efficiency gains

Extended equipment life

Faster problem resolution

Strengthened safety culture

Workforce competency development

ROI:

Reduced unplanned downtime

Lower energy costs

Decreased maintenance expenses

Improved quality and pricing

Enhanced compliance

Knowledge retention