Fundamentals and Best Practices for Ammonia Plants Operation and Maintenance

$5500.00

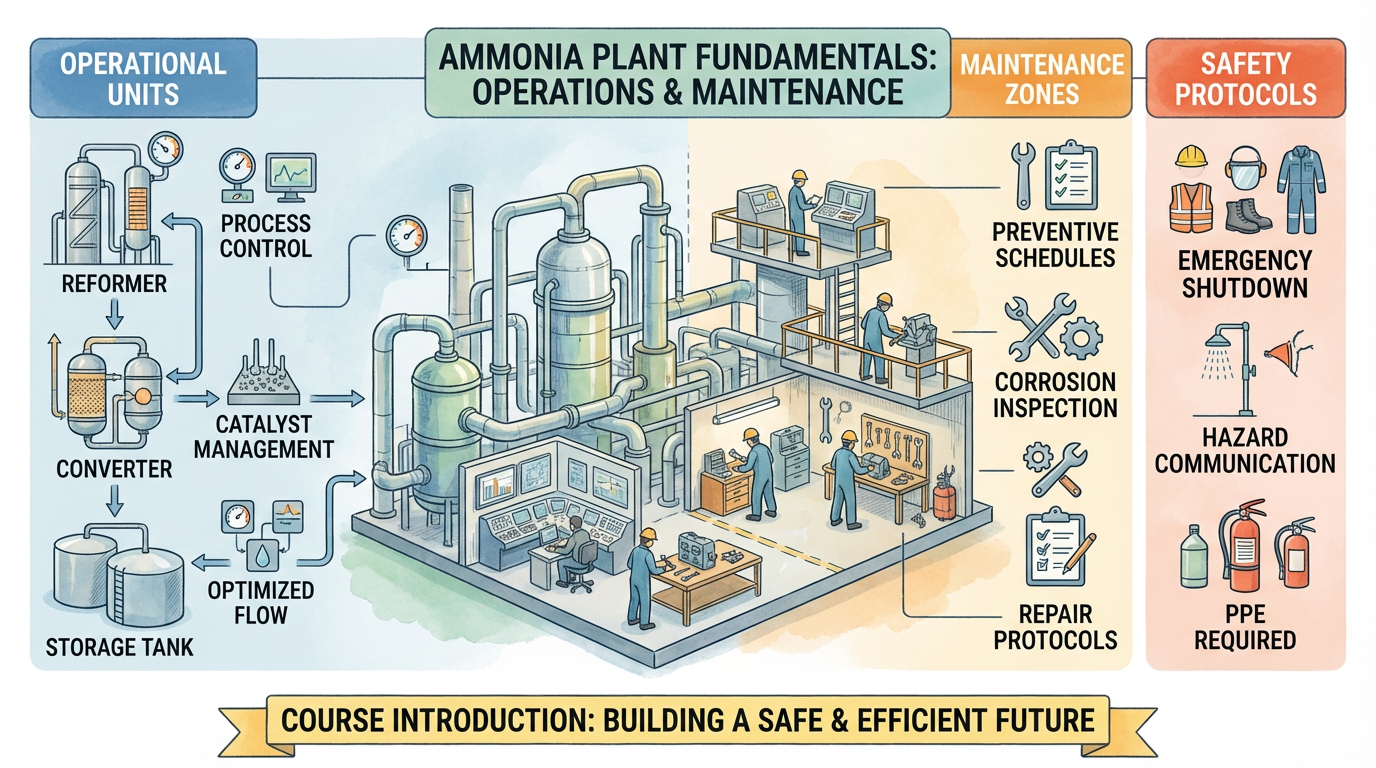

Fundamentals and Best Practices for Ammonia Plants Operation and Maintenance: 5-Day Professional Training Course

Course Overview

This intensive 5-day ammonia plant operations and maintenance training equips participants with practical skills, industry best practices, and hands-on knowledge for optimizing ammonia production facilities. Designed for plant operators, maintenance engineers, reliability specialists, and production supervisors, this course bridges theoretical concepts with real-world operational excellence.

Target Audience: Plant operators, maintenance technicians, instrumentation engineers, reliability engineers, production managers, shift supervisors, and maintenance planners working in ammonia manufacturing facilities.

Course Objectives:

Master operational procedures and safety protocols for ammonia plants

Implement preventive and predictive maintenance strategies

Optimize plant performance and energy efficiency

Troubleshoot common operational problems effectively

Apply industry best practices for reliability and uptime maximization

Day 1: Operational Fundamentals and Safety Excellence

Morning Session: Ammonia Plant Operations Overview

Understanding Integrated Operations

The opening session establishes comprehensive understanding of ammonia production operations, covering complete plant workflows from startup to steady-state operation. Participants learn:

Process flow integration across all major units

Normal operating parameters and control philosophies

Startup, shutdown, and emergency procedures

Shift handover protocols and communication standards

Production rate optimization strategies

Key performance indicators (KPIs) for ammonia plants

Operational Modes and Flexibility:

Full-capacity operations and turndown strategies

Load following and demand response capabilities

Seasonal operation considerations

Feedstock switching procedures (natural gas to alternative feeds)

Integration with downstream urea or other derivative plants

Afternoon Session: Safety Management and Risk Mitigation

Ammonia Plant Safety Fundamentals

Safety represents the paramount priority in ammonia operations. This critical session covers:

Process Safety Management (PSM):

Hazard identification specific to ammonia manufacturing

Process hazard analysis (PHA) methodologies

Management of change (MOC) procedures

Pre-startup safety reviews (PSSR)

Incident investigation and root cause analysis

Safety culture development and behavioral safety

Ammonia-Specific Hazards:

Toxic exposure risks and threshold limit values

High-pressure system hazards

High-temperature equipment dangers

Hydrogen safety considerations

Confined space entry in ammonia environments

Emergency Response Procedures:

Ammonia leak detection systems and alarm management

Emergency shutdown (ESD) system operations

Evacuation procedures and muster point protocols

Personal protective equipment (PPE) including SCBA usage

First aid for ammonia exposure

Coordination with emergency responders

Permit Systems:

Hot work permits and fire prevention

Lock-out/tag-out (LOTO) procedures

Confined space entry permits

Excavation and opening equipment permits

Day 2: Operational Best Practices and Process Optimization

Morning Session: Reforming Section Operations

Primary and Secondary Reformer Management

Mastering reformer operations is crucial for plant efficiency and reliability:

Primary Reformer Operations:

Firing pattern optimization for uniform tube temperatures

Draft control and combustion air management

Tube skin temperature monitoring and alarming

Steam-to-carbon ratio control for carbon prevention

Fuel gas quality management

Reformer efficiency calculations and energy optimization

Operational Best Practices:

Burner inspection and cleaning schedules

Tube temperature balancing techniques

Managing tube creep and life assessment

Detecting and preventing tube failures

Planned decoking procedures when required

Secondary Reformer Operations:

Air-to-gas ratio control for optimal H₂:N₂ ratio

Refractory management and inspection

Outlet temperature control and distribution

Catalyst bed monitoring and performance tracking

Afternoon Session: Shift Conversion and Gas Purification

High and Low Temperature Shift Operations

Optimizing water-gas shift converters for maximum efficiency:

HTS and LTS Best Practices:

Temperature profile management and control

Inlet gas composition monitoring

Steam injection optimization

CO slip minimization techniques

Preventing catalyst sintering and deactivation

Condensate management in shift section

CO₂ Removal System Operations:

Amine or carbonate solution management

Absorber and stripper performance optimization

Solution strength and circulation rate control

Foaming detection and prevention

Corrosion monitoring and inhibitor addition

Reclaimer operations for solution purification

Energy optimization in regeneration

Methanation Operations:

Temperature control for optimal conversion

Preventing temperature runaways

Catalyst performance monitoring

Achieving ultra-low CO/CO₂ specifications

Day 3: Synthesis Loop Operations and Compression Systems

Morning Session: Ammonia Synthesis Optimization

Synthesis Converter Operations

The ammonia synthesis loop represents the production heart requiring precision control:

Catalyst Management Best Practices:

Catalyst activation procedures and monitoring

Temperature profile optimization across beds

Quench gas distribution control

Catalyst aging and activity tracking

Maximizing catalyst life (10-15 years potential)

Poison prevention (oxygen, water, CO, chlorides, sulfur)

Synthesis Loop Optimization:

Maintaining optimal H₂:N₂ ratio (stoichiometric 3:1)

Purge gas rate optimization for inert control

Conversion efficiency maximization

Pressure optimization for best economics

Recycle compressor performance management

Loop stability and control strategies

Troubleshooting Common Issues:

Low conversion diagnosis and correction

Temperature excursions and remediation

Pressure fluctuations and control problems

Catalyst activity decline investigation

Afternoon Session: Compression and Refrigeration Systems

Compressor Operations and Maintenance

Reliable compressor operation is critical for continuous ammonia production:

Centrifugal Compressor Operations:

Performance curves and operating envelope

Surge prevention and anti-surge control

Fouling detection and online water washing

Vibration monitoring and analysis

Seal system management

Efficiency optimization techniques

Reciprocating Compressor Management:

Valve performance monitoring

Pulsation dampener maintenance

Cylinder condition assessment

Capacity control strategies

Rod loading calculations

Ammonia Refrigeration Operations:

Refrigeration cycle optimization

Compressor staging and control

Defrost cycle management

Refrigerant inventory management

Leak detection and repair programs

Energy efficiency improvements

Day 4: Maintenance Excellence and Reliability Strategies

Morning Session: Preventive Maintenance Programs

Structured Maintenance Planning

Implementing world-class preventive maintenance (PM) programs:

Equipment-Specific PM Strategies:

Reformer tube inspection programs (ultrasonic testing, metallurgy sampling)

Catalyst replacement planning and forecasting

Heat exchanger cleaning schedules

Rotating equipment maintenance intervals

Pressure vessel inspections (API 510 requirements)

Piping integrity management (API 570)

Maintenance Planning Best Practices:

Work order management systems

Spare parts inventory optimization

Maintenance scheduling for minimal production impact

Coordination between operations and maintenance

Contractor management and safety integration

Turnaround Planning:

Major turnaround scheduling (typically 2-4 year intervals)

Scope development and critical path planning

Resource allocation and budgeting

Simultaneous operations (SIMOPS) management

Post-turnaround startup procedures

Afternoon Session: Predictive Maintenance Technologies

Condition-Based Monitoring

Leveraging modern technologies for predictive maintenance (PdM):

Vibration Analysis:

Rotating equipment monitoring programs

Bearing condition assessment

Unbalance and misalignment detection

Resonance identification and mitigation

Trend analysis and failure prediction

Thermography Applications:

Reformer tube temperature monitoring

Electrical system hot spot detection

Refractory condition assessment

Insulation effectiveness evaluation

Steam trap performance verification

Advanced Monitoring Techniques:

Ultrasonic testing for leak detection and thickness measurement

Oil analysis programs for gearboxes and compressors

Motor current signature analysis (MCSA)

Acoustic emission for pressure vessel monitoring

Online process analyzers for catalyst performance

Reliability-Centered Maintenance (RCM):

Failure mode effects analysis (FMEA)

Criticality ranking and prioritization

Optimization of maintenance intervals

Balancing PM, PdM, and run-to-failure strategies

Day 5: Troubleshooting, Energy Management, and Continuous Improvement

Morning Session: Advanced Troubleshooting

Systematic Problem-Solving Methodologies

Developing expertise in ammonia plant troubleshooting:

Common Operational Problems:

Reformer flame instability and pulsations

High CO slip in shift converters

CO₂ removal system flooding or foaming

Synthesis converter hot spots or temperature excursions

Compressor surge and performance deterioration

Ammonia product off-specification issues

Diagnostic Approaches:

Root cause analysis techniques (5-Why, Fishbone diagrams)

Process parameter trending and data analysis

Material balance calculations for leak detection

Heat balance verification

Catalyst performance evaluation methods

Case Studies:

Real-world troubleshooting scenarios from operating plants with solutions and lessons learned.

Afternoon Session: Energy Efficiency and Performance Optimization

Energy Management Best Practices

Ammonia plants are energy-intensive, making efficiency optimization economically critical:

Energy Consumption Analysis:

Benchmark energy consumption (28-35 MMBtu/ton NH₃ typical)

Identifying energy waste opportunities

Heat integration and pinch analysis

Steam system optimization

Condensate recovery maximization

Optimization Strategies:

Reformer thermal efficiency improvements

Process air compressor optimization

Synthesis loop pressure optimization

Refrigeration system efficiency enhancement

Variable speed drive applications

Waste heat recovery projects

Performance Monitoring:

Key performance indicators (KPIs) tracking

Energy intensity metrics

Production rate optimization

Yield improvement initiatives

Greenhouse gas emissions reduction

Continuous Improvement and Digitalization

Modern Plant Management

Embracing Industry 4.0 technologies for ammonia plants:

Digital Transformation:

Advanced process control (APC) implementation

Artificial intelligence and machine learning applications

Digital twin technology for optimization

Predictive analytics for maintenance

Mobile technologies for field operations

Cloud-based monitoring and remote support

Operational Excellence Programs:

Lean manufacturing principles in ammonia production

Six Sigma methodologies for variability reduction

Total productive maintenance (TPM)

Operator-driven reliability programs

Knowledge capture and transfer systems

Environmental and Sustainability:

Emissions monitoring and reduction strategies

Water conservation initiatives

Waste minimization programs

Green ammonia transition planning

Carbon footprint reduction pathways

Course Deliverables and Certification

Participants Receive:

Comprehensive operations and maintenance manual

Troubleshooting flowcharts and decision trees

PM/PdM procedure templates and checklists

Industry benchmark data and case studies

Professional certificate of completion

Access to online resource library and expert network

Interactive Learning Methods:

Simulator-based training scenarios

Hands-on equipment demonstrations

Group troubleshooting exercises

Plant walk-down simulations

Q&A sessions with industry experts

Why Invest in This Training?

This ammonia operations and maintenance course delivers immediate ROI through:

Enhanced operational reliability and reduced downtime

Improved safety performance and regulatory compliance

Energy efficiency gains and cost reduction

Extended equipment life through proper maintenance

Faster problem resolution and troubleshooting

Empowered workforce with industry best practices

Ideal for: Facilities seeking operational excellence, new operators requiring comprehensive training, experienced personnel updating skills, and organizations implementing reliability programs.