Fundamental principles of welding and welding techniques

$5500.00

Fundamental Principles of Welding and Welding Techniques: 5-Day Professional Training Course

Course Overview

This intensive 5-day welding training course delivers comprehensive instruction in fundamental welding principles and modern welding techniques tailored for professionals across Saudi Arabia (KSA), Oman, UAE, Qatar, Kuwait, Bahrain, and African markets. Designed for both beginners and intermediate practitioners, this program covers essential welding safety standards, metal joining processes, and industry-certified welding methods applicable to oil and gas, construction, manufacturing, and automotive sectors throughout the GCC region.

Target Audience

Welding technicians and maintenance personnel in KSA and GCC industries

Construction workers and fabrication specialists across Africa

Engineering students pursuing welding certification in Oman and Middle East

Industrial supervisors overseeing welding operations in manufacturing facilities

Quality control inspectors requiring welding knowledge for GCC projects

Day 1: Welding Fundamentals and Safety Standards

Morning Session: Introduction to Welding Technology

History and evolution of welding processes in industrial applications

Metal properties and metallurgy basics: carbon steel, stainless steel, aluminum

Heat effects on metals: thermal expansion, distortion control, residual stress

Welding symbols and blueprint reading according to AWS and ISO standards

Industry standards compliance for Saudi Aramco, ADNOC, and African petroleum sectors

Afternoon Session: Workplace Safety and PPE

Occupational safety regulations in KSA, Oman, and GCC countries

Personal protective equipment (PPE) requirements: welding helmets, gloves, protective clothing

Welding hazards identification: electrical safety, fire prevention, fume exposure

Ventilation systems and respiratory protection for confined spaces

Emergency response procedures and first aid for welding injuries

OSHA and Saudi safety standards implementation

Learning Outcomes: Understanding welding fundamentals, metal behavior, and comprehensive safety protocols required across GCC industrial environments.

Day 2: Arc Welding Processes - SMAW and GTAW

Morning Session: Shielded Metal Arc Welding (SMAW/Stick Welding)

SMAW equipment setup: welding machines, electrode holders, ground clamps

Electrode classification system: E6010, E6011, E7018 specifications

Striking and maintaining arc stability techniques

Bead patterns and weaving methods for different joint configurations

Current settings optimization for various material thicknesses

Common defects prevention: porosity, undercut, slag inclusion

Afternoon Session: Gas Tungsten Arc Welding (GTAW/TIG)

GTAG welding principles and equipment components: torch, tungsten electrodes, gas regulators

Inert gas selection: Argon, Helium, mixed gases for different metals

AC vs DC current applications for aluminum and steel welding

Filler rod selection and feeding techniques

Precision welding for critical applications in aerospace and petrochemical industries

Practical exercises: lap joints, butt joints, T-joints on stainless steel

Learning Outcomes: Mastery of two fundamental arc welding processes widely used in KSA construction projects and GCC manufacturing facilities.

Day 3: Gas Metal Arc Welding and Flux-Cored Arc Welding

Morning Session: GMAW (MIG/MAG Welding)

Semi-automatic welding systems and wire feed mechanisms

Shielding gas combinations: CO2, Argon-CO2 mixtures for steel fabrication

Metal transfer modes: short-circuit, globular, spray, pulse transfer

Voltage and wire feed speed relationships for optimal penetration

High-productivity welding for automotive manufacturing and structural steel projects

Applications in African infrastructure development and GCC construction boom

Afternoon Session: Flux-Cored Arc Welding (FCAW)

Self-shielded vs gas-shielded FCAW systems

Outdoor welding advantages for pipeline construction in desert environments

High deposition rates for shipbuilding and heavy equipment fabrication

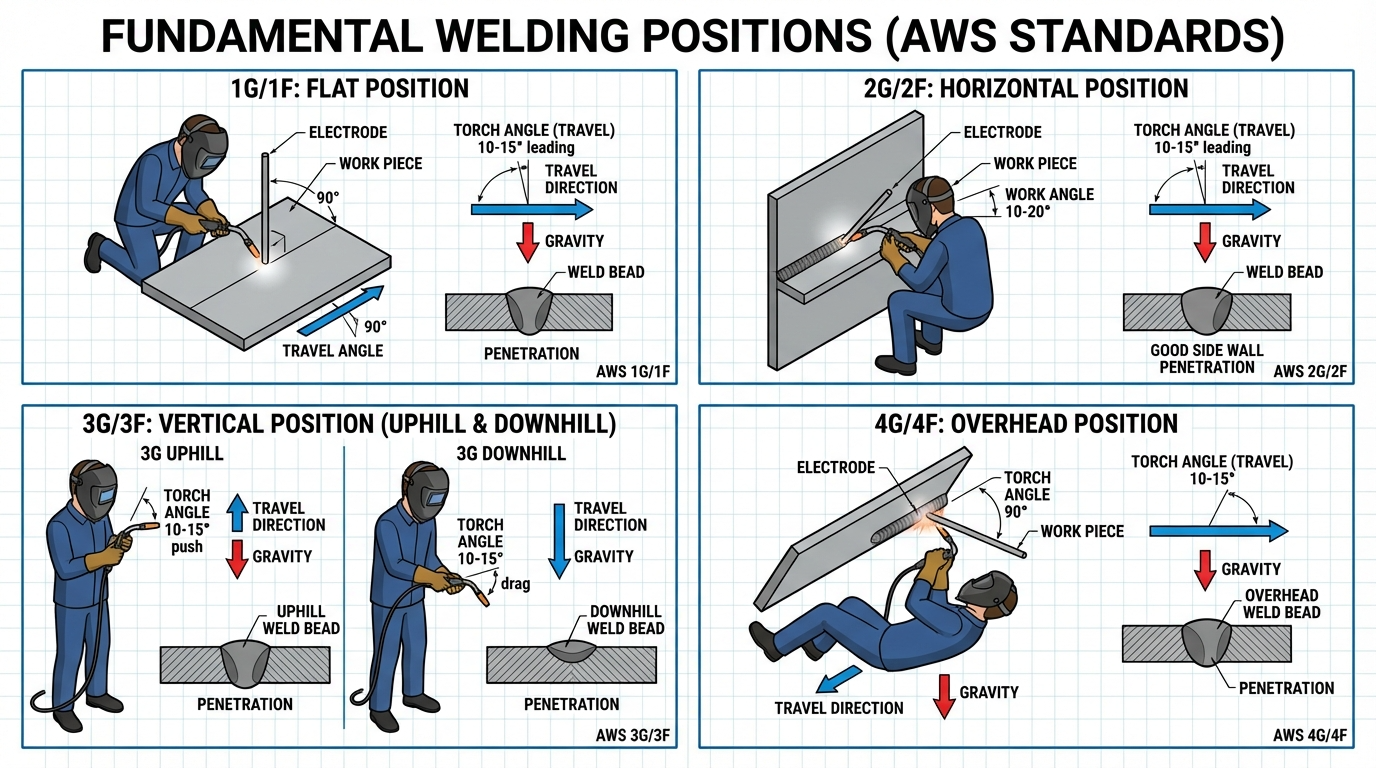

Welding positions mastery: flat, horizontal, vertical, overhead

Quality assurance techniques for pressure vessel welding in oil and gas sector

Hands-on practice: multi-pass welding on thick plates

Learning Outcomes: Proficiency in high-efficiency welding methods essential for Saudi Arabia’s Vision 2030 industrial projects and African infrastructure expansion.

Day 4: Specialized Welding Techniques and Advanced Applications

Morning Session: Oxy-Fuel Welding and Cutting

Oxy-acetylene equipment setup and flame adjustment techniques

Neutral, oxidizing, and carburizing flames for different applications

Brazing and soldering fundamentals for HVAC and refrigeration systems

Thermal cutting processes: plasma cutting, oxy-fuel cutting for demolition

Metal preparation and edge preparation methods

Cost-effective solutions for small-scale workshops across Africa and Oman

Afternoon Session: Pipe Welding and Positional Welding

Pipeline welding certification requirements for oil and gas industry in GCC

Root pass, fill passes, and cap pass techniques on schedule 40 and 80 pipes

6G position welding: the most challenging certification test

Weld inspection criteria: visual examination, dye penetrant testing

API and ASME standards for pressure piping systems

Practical exercises: carbon steel pipe welding in 5G position

Learning Outcomes: Advanced skills for specialized welding applications in KSA’s petrochemical complexes, Oman’s gas facilities, and African mining operations.

Day 5: Weld Quality, Inspection, and Certification

Morning Session: Weld Defects and Quality Control

Common welding defects identification: cracks, porosity, incomplete fusion, undercut

Root causes analysis and corrective action procedures

Non-destructive testing (NDT) methods: visual inspection, ultrasonic testing, radiography

Welding procedure specifications (WPS) development

Welder performance qualification (WPQ) according to AWS D1.1 standards

Documentation and traceability for Saudi Aramco approved contractors

Afternoon Session: Career Pathways and Certification

International welding certifications: AWS, ASME, TÜV, Lloyd’s Register

GCC welding job market opportunities in Saudi Arabia, UAE, Qatar

Salary expectations for certified welders in Middle East and Africa (2024-2026)

Continuing professional development resources

Business opportunities: starting welding service companies in emerging African markets

Final assessment and course certification

Learning Outcomes: Comprehensive understanding of quality standards and clear pathways to professional certification for employment in high-demand GCC industrial sectors.

Course Benefits for GCC and African Markets

✓ Industry-relevant curriculum aligned with Saudi Aramco, ADNOC, and international standards

✓ Hands-on training with modern welding equipment used in GCC facilities

✓ Bilingual instruction available (English/Arabic) for regional accessibility

✓ Job placement assistance with leading contractors in KSA, Oman, UAE

✓ Certification preparation for AWS and ASME qualification tests

✓ Portable skills applicable across multiple industries and African nations

Investment in Your Future

This welding training course represents essential skills development for the booming construction, energy, and manufacturing sectors across Saudi Arabia, Oman, Kuwait, Qatar, UAE, Bahrain, Egypt, Nigeria, South Africa, and Kenya. With the GCC diversification initiatives (Saudi Vision 2030, Oman Vision 2040) and African infrastructure expansion, certified welders command premium salaries and enjoy excellent career mobility.

Enroll today to secure your position in the high-demand welding profession across the Middle East and Africa!

Keywords: welding course KSA, welding training Saudi Arabia, welding certification Oman, GCC welding jobs, welding techniques Africa, professional welding course Middle East, AWS welding certification, SMAW training, TIG welding course, MIG welding GCC, pipeline welding certification, oil and gas welding jobs, Saudi Aramco welding standards, ADNOC welding requirements, African welding training programs