Flow assurance and hydraulics

$5500.00

Flow Assurance & Hydraulics: Comprehensive 5-Day Training Course

Course Overview

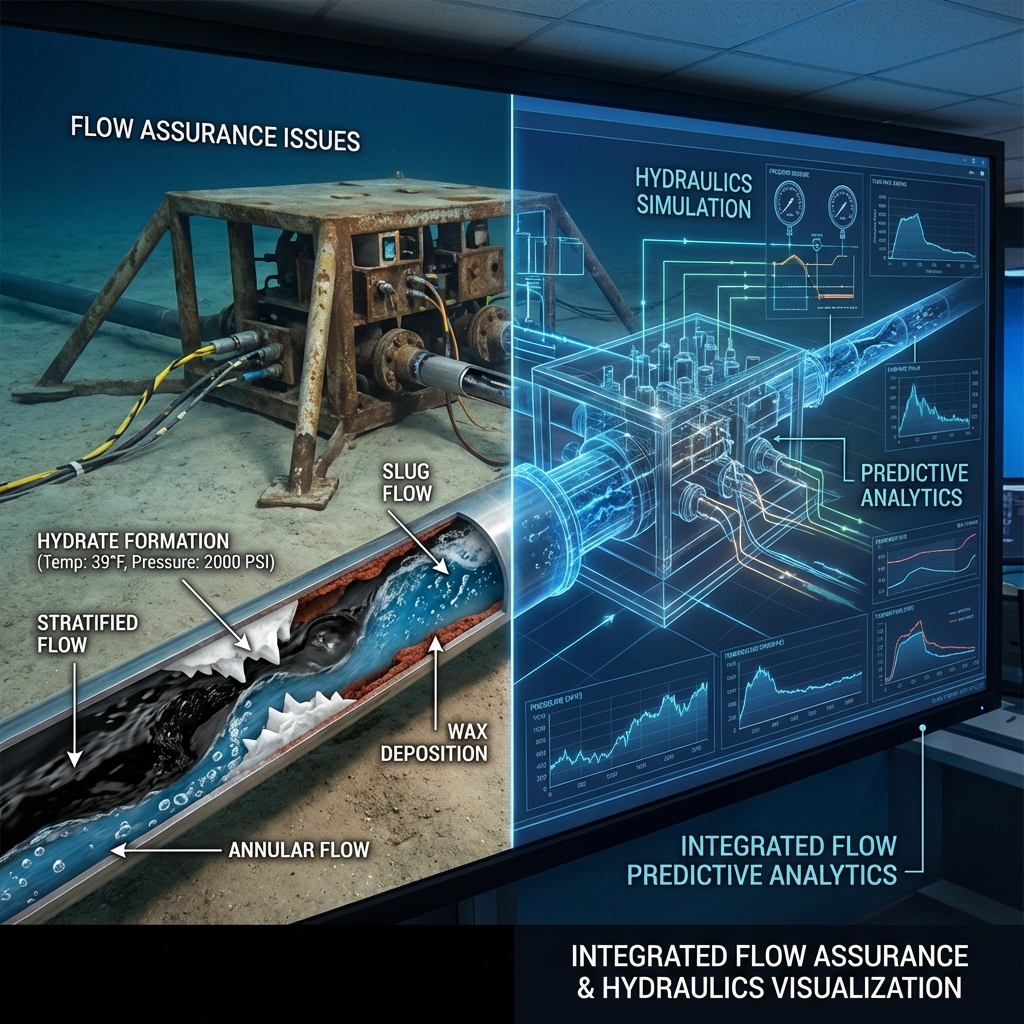

This specialized Flow Assurance and Hydraulics training program delivers critical expertise for oil & gas professionals across the Kingdom of Saudi Arabia (KSA), Oman, GCC countries (UAE, Qatar, Kuwait, Bahrain), and Africa. The course covers multiphase flow fundamentals, flow assurance challenges, hydraulic design, wax and hydrate management, pipeline optimization, and production system design essential for ensuring reliable hydrocarbon transportation from reservoirs to processing facilities in upstream, midstream, and offshore operations.

With the Middle East producing over 30 million barrels per day of oil and operating extensive subsea infrastructure in the Arabian Gulf, Red Sea, and Africa’s offshore basins, this training addresses critical competencies for professionals at Saudi Aramco, PDO (Petroleum Development Oman), ADNOC, Qatar Energy, Kuwait Oil Company, Chevron, TotalEnergies, Eni, and other operators managing flow assurance in challenging environments including deepwater fields, long tiebacks, heavy oil, high-pressure/high-temperature (HPHT) wells supporting regional production growth and Saudi Vision 2030 energy sector development.

Target Audience

Flow Assurance Engineers in oil & gas operations across Saudi Arabia, Oman, GCC, Africa

Production Engineers optimizing well and facility performance

Pipeline Engineers designing transportation systems

Subsea Engineers managing offshore production systems

Operations Engineers troubleshooting flow assurance issues

Facilities Engineers designing separation and processing systems

Project Engineers in upstream developments and field expansions

Reservoir Engineers interfacing with production systems

Day 1: Multiphase Flow Fundamentals & Hydraulics

Morning Session: Fluid Properties & Flow Regimes

Fluid characterization: crude oil, natural gas, water, condensate properties

PVT (Pressure-Volume-Temperature) behavior: bubble point, dew point, gas-oil ratio (GOR)

Fluid viscosity: temperature and pressure effects, heavy oil challenges in Saudi Arabia

API gravity, density, compressibility factors for GCC crudes

Flow regimes: single-phase vs. multiphase flow patterns

Gas-liquid flow patterns: bubble, slug, churn, annular flow in pipes

Flow pattern maps: horizontal, vertical, inclined pipe configurations

Transition criteria: superficial velocities, dimensionless numbers (Froude, Weber, Reynolds)

Slug flow characteristics: liquid holdup, slug length, frequency

Severe slugging in pipelines and risers: causes, impacts, mitigation

Regional considerations: Arabian Gulf offshore, Red Sea developments, Oman mountainous terrain

Case studies: Safaniya offshore (Saudi Arabia), Khazzan gas field (Oman)

Afternoon Session: Hydraulic Calculations & Pressure Drop

Single-phase hydraulics: Darcy-Weisbach equation, friction factors, Moody diagram

Reynolds number: laminar, transitional, turbulent flow regimes

Pipe roughness effects: new vs. corroded pipes, fouling impact

Multiphase pressure drop correlations: Beggs & Brill, Dukler, Taitel-Dukler

Holdup calculations: liquid fraction in pipe, slip between phases

Vertical vs. horizontal pressure gradients: hydrostatic, friction, acceleration components

Two-phase multiplier concept: relating multiphase to single-phase pressure drop

Erosional velocity: API RP 14E criteria preventing equipment damage

Critical flow: choked flow conditions, sonic velocity in gas systems

Pressure drop in fittings: valves, bends, tees, restrictions

Software tools: PIPESIM, OLGA, PIPEPHASE, LedaFlow for hydraulic modeling

Workshop: Hydraulic calculations for oil/gas pipeline systems

Day 2: Flow Assurance Challenges - Hydrates & Wax

Morning Session: Gas Hydrate Formation & Management

Hydrate fundamentals: crystalline structures (sI, sII, sH), cage molecules

Hydrate formation conditions: pressure-temperature envelopes, guest molecules

Thermodynamic modeling: hydrate prediction curves, CSMGem, PVTsim

Factors affecting hydrate formation: water content, salinity, gas composition

Hydrate risks: pipeline blockages, equipment damage, safety hazards

Regional challenges: deepwater Gulf (Saudi Arabia, UAE), subsea tiebacks

Prevention strategies: keeping outside hydrate zone (dehydration, heating, insulation)

Thermodynamic inhibitors: methanol (MeOH), monoethylene glycol (MEG), triethylene glycol (TEG)

Low-dosage hydrate inhibitors (LDHI): kinetic inhibitors (KHI), anti-agglomerants (AA)

Chemical injection design: dosage rates, injection points, recovery systems

MEG regeneration systems: reclaiming and reusing glycol in offshore facilities

Operational practices: depressurization, heating, pigging strategies

Hydrate remediation: blockage removal techniques, hot oil circulation, depressurization

Case studies: Deepwater developments (African offshore), Qatar North Field

Afternoon Session: Wax Deposition & Paraffin Management

Wax chemistry: paraffin composition, wax appearance temperature (WAT), pour point

Factors influencing wax deposition: temperature, pressure, shear rate, oil composition

Heavy crude challenges: Saudi Arabian heavy oil fields, Omani viscous crudes

Wax deposition mechanisms: molecular diffusion, shear dispersion, Brownian diffusion

Prediction models: thermodynamic (Coutinho), kinetic deposition models

Wax thickness growth: impact on pressure drop, flow restriction, pigging frequency

Prevention methods: thermal insulation, heated pipelines, chemical inhibitors

Pour point depressants (PPD) and wax inhibitors: chemistry, application, dosage

Thermal management: maintaining temperature above WAT through insulation, heating

Heated pipelines vs. insulated flowlines: economics, operational considerations

Remediation techniques: mechanical pigging, chemical treatment, hot oil circulation

Pig types: cleaning pigs, gauge pigs, intelligent pigs for wax removal

Pigging operations: launcher/receiver design, pig tracking, scheduling frequency

Workshop: Wax deposition risk assessment and mitigation strategy development

Day 3: Asphaltene, Scale & Corrosion Management

Morning Session: Asphaltene Precipitation & Control

Asphaltene characteristics: complex molecules, colloidal stability, flocculation

Precipitation triggers: pressure drop, composition changes, mixing incompatible crudes

Onset pressure: predicting asphaltene instability, P-T phase envelopes

Saudi Arabian crude blending challenges: asphaltene compatibility issues

Impact on production: wellbore plugging, pipeline deposition, separator problems

Laboratory testing: asphaltene content, stability tests, deposition tendency

Prevention strategies: pressure management above onset, chemical dispersants

Asphaltene inhibitors and dispersants: chemistry, screening, field application

Remediation: solvent treatment (xylene, toluene, aromatic solvents), mechanical removal

Pipeline pigging for asphaltene deposits in Saudi Aramco systems

Monitoring programs: pressure drop trends, production decline analysis

Afternoon Session: Scale & Corrosion in Production Systems

Scale formation: calcium carbonate, barium sulfate, strontium sulfate, iron compounds

Scaling mechanisms: pressure drop, temperature change, water incompatibility

Prediction: saturation indices, scaling tendency, mixing seawater with formation water

Common in GCC waterflooding operations (Ghawar, Burgan fields)

Scale inhibitors: threshold inhibitors, phosphonates, polymers, green inhibitors

Squeeze treatments: bullheading, placement design, return curves

Corrosion mechanisms: sweet (CO2), sour (H2S), oxygen, microbiologically influenced (MIC)

Corrosion rates: material selection, monitoring, inhibition strategies

Internal corrosion management: chemical inhibitors, coatings, material upgrades

Corrosion monitoring: coupons, electrical resistance probes, ultrasonic measurements

Materials selection: carbon steel, CRAs (corrosion-resistant alloys), duplex, super duplex

Case studies: Sour gas fields (Khuff formations Saudi Arabia), H2S management (Oman)

Day 4: Pipeline Design & Subsea Systems

Morning Session: Pipeline Flow Assurance Design

Design philosophy: steady-state vs. transient conditions, normal vs. upset scenarios

Operating envelope definition: flow rates, pressures, temperatures, fluid properties

Thermal-hydraulic modeling: coupled heat transfer and pressure drop analysis

Insulation design: preventing hydrate/wax formation, maintaining flow temperature

Pipe-in-pipe (PIP) systems: vacuum insulation, syntactic foam, aerogel for deepwater

Critical for Arabian Gulf cold seabed temperatures despite surface heat

Cooldown analysis: shutdown scenarios, restart requirements, cooldown time

Thermal insulation requirements for long shutdowns in offshore systems

Start-up procedures: pre-commissioning, initial filling, gradual rate increase

Shutdown and restart: depressurization, nitrogen purging, inhibitor injection

Pigging strategy: cleaning frequency, hydrate prevention during pigging, pig traps

Slug catchers: design for liquid handling, separator sizing

Riser design: severe slugging mitigation, top-side choking, gas lift

Case studies: Saudi Aramco offshore pipelines, ADNOC subsea developments

Afternoon Session: Subsea Production Systems

Subsea architecture: manifolds, templates, flowlines, risers, umbilicals

Flow assurance in subsea systems: no surface access, limited intervention capability

Active heating systems: direct electrical heating (DEH), trace heating

Passive insulation: coatings, PIP systems, burying flowlines

Chemical injection: hydrate inhibitors, scale inhibitors, corrosion inhibitors, demulsifiers

Umbilical design: hydraulic, electrical, chemical injection lines

Subsea processing: separation, boosting, compression, reducing topside loading

Benefits in flow assurance: pressure maintenance, reduced transport requirements

Deepwater challenges: high pressures, low temperatures, long tiebacks

African deepwater (Nigeria, Angola, Mozambique): 2,000-3,000m water depths

Well testing: multiphase flow meters, sampling, well performance monitoring

Intervention strategies: ROVs, coiled tubing, subsea well control

Reliability engineering: equipment selection, redundancy, maintainability

Workshop: Subsea system flow assurance design exercise

Day 5: Advanced Topics & Operational Optimization

Morning Session: Transient Analysis & Simulation

Steady-state vs. transient modeling: when transient analysis is required

Dynamic simulation software: OLGA, LedaFlow for transient multiphase flow

Startup scenarios: line filling, rate ramp-up, arrival of first production

Pressure wave propagation, liquid accumulation, terrain slugging

Shutdown analysis: blowdown, inventory management, cooldown curves

Restart after shutdown: pressure buildup, heating requirements, pigging

Operational transients: flowrate changes, well shut-ins, compressor trips

Slug flow in pipelines: liquid surge volumes, separator design margins

Terrain-induced slugging: hilly terrain, pipeline low points, riser-induced slugging

Mitigation: choking, gas lift, slug suppression control

Pigging simulations: pig speed, liquid production, pressure variations

Safety systems: pressure relief, emergency shutdown valves, blowdown sizing

Black oil vs. compositional models: selection criteria for complex fluids

Case studies: Transient analysis for Saudi offshore, Oman field developments

Afternoon Session: Flow Assurance Monitoring & Optimization

Real-time monitoring: pressure, temperature, flow rate, density measurements

Multiphase flow meters: Venturi, Coriolis, gamma densitometry, clamp-on ultrasonic

Distributed temperature sensing (DTS): fiber optic monitoring for pipelines

Detecting hydrate formation, wax deposition, leaks along Saudi Aramco pipelines

Production optimization: maximizing throughput within flow assurance constraints

Well testing and allocation: understanding individual well contributions

Artificial lift selection: gas lift, ESPs, considering flow assurance impacts

Network modeling: integrated asset models, field-wide optimization

Digital technologies: machine learning for prediction, digital twins, AI diagnostics

Predictive maintenance: anticipating flow assurance problems before failures

Chemical management optimization: dosage optimization, injection scheduling

Cost reduction while maintaining flow assurance integrity

Flow assurance management plans (FAMP): lifecycle approach from design to abandonment

Benchmarking: KPIs, industry best practices, continuous improvement

Lessons learned: major incidents, near-misses, successful interventions

Final workshop: Integrated flow assurance case study (GCC offshore field development)

Learning Outcomes

Upon completion, participants will be able to:

Calculate multiphase flow hydraulics for oil and gas production systems

Predict and prevent hydrate formation through appropriate inhibition strategies

Manage wax deposition risks using thermal, chemical, and mechanical methods

Design flow assurance solutions for pipelines and subsea systems

Conduct transient analysis for startup, shutdown, and operational scenarios

Select appropriate mitigation strategies for asphaltene, scale, and corrosion

Use industry-standard software (PIPESIM, OLGA, PIPEPHASE) for flow modeling

Develop flow assurance management plans for field development projects

Optimize production operations within flow assurance constraints

Course Delivery & Certification

Format: Technical lectures, hydraulic workshops, case studies, simulation demonstrations, hands-on exercises

Software: Introduction to PIPESIM, OLGA concepts for flow assurance modeling

Materials: Comprehensive manual, calculation tools, flow assurance charts, case study library, industry standards

Certification: Professional certificate recognized across KSA, Oman, UAE, Qatar, Kuwait, Bahrain, Africa

Language: English (Arabic support available)

CPD Credits: Continuing professional development for petroleum engineers

Locations: Riyadh, Dhahran, Khobar (KSA), Muscat (Oman), Dubai, Abu Dhabi, Doha, Lagos, Luanda, Cairo

Why This Course is Critical for the Region

The GCC offshore developments (Safaniya, Manifa, Marjan, Upper Zakum, North Field) involve complex flow assurance challenges. Saudi Aramco’s offshore production exceeds 3 million bpd requiring reliable transportation. Oman’s Khazzan tight gas field faces unique condensate and water management challenges. African deepwater (pre-salt Brazil analog offshore Angola/Mozambique) demands advanced flow assurance solutions. Flow assurance failures cost $1-10 million per day in deferred production.

This training delivers practical expertise incorporating international best practices, Saudi Aramco operational experience, Schlumberger/Halliburton methodologies, addressing specific regional challenges: high temperatures, sour gas, heavy oil, carbonate reservoirs, long-distance transport, supporting upstream efficiency and Saudi Vision 2030 production sustainability goals.

Ensure flow. Prevent blockages. Optimize production.