Extensive 2 Days Masterclass – Corrosion Under Insulation (CUI)

$2000.00

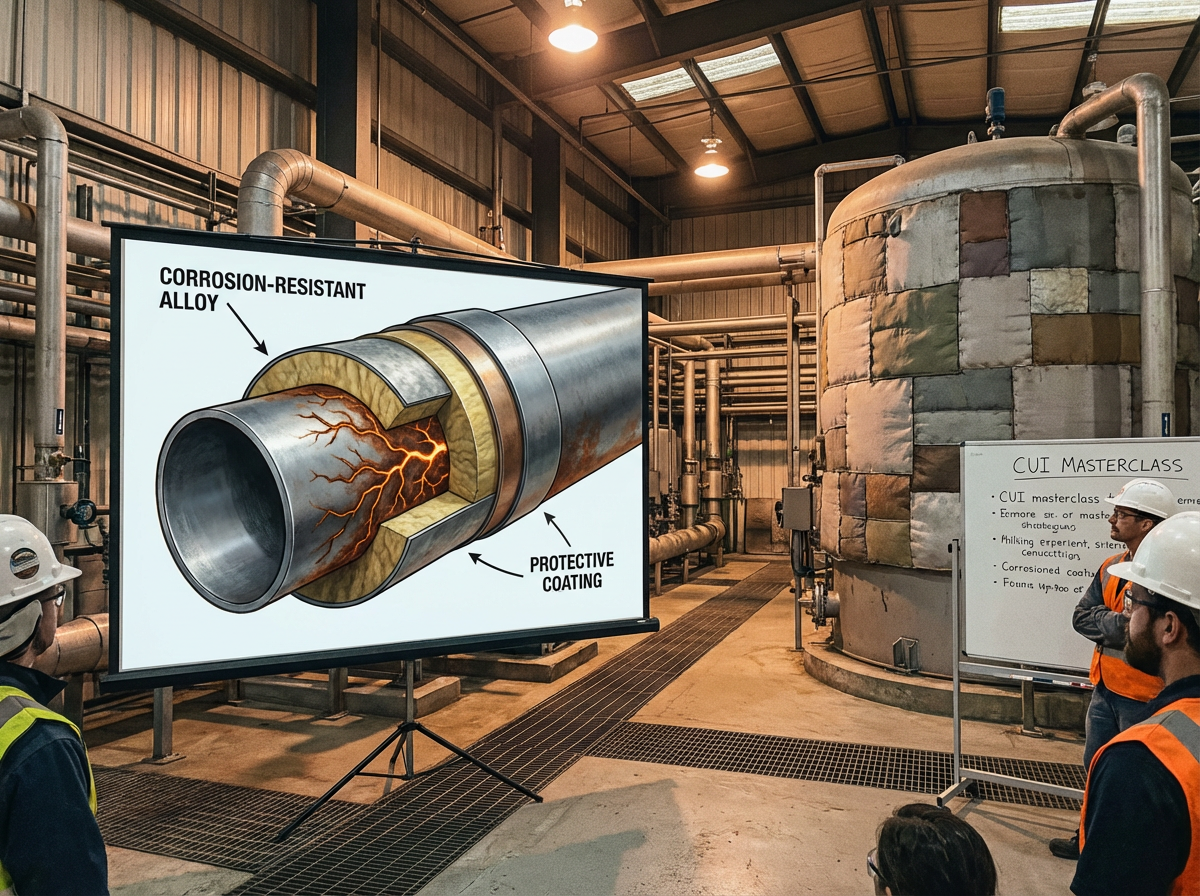

Extensive 2-Day Masterclass: Corrosion Under Insulation (CUI)

Course Overview

This intensive 2-day CUI masterclass provides comprehensive knowledge of corrosion under insulation phenomena, inspection techniques, prevention strategies, and management programs. Designed for integrity engineers, inspection professionals, corrosion specialists, and maintenance managers across all industries where insulated equipment operates.

Target Audience: Integrity engineers, corrosion specialists, inspection professionals, maintenance managers, reliability engineers, plant engineers, NDT technicians, and asset management professionals in petrochemical, power generation, and manufacturing facilities.

Course Objectives:

Understand CUI and CUI mechanisms and influencing factors

Master inspection and detection techniques for CUI

Implement effective prevention and mitigation strategies

Develop comprehensive CUI management programs

Apply risk-based inspection approaches to CUI

Ensure regulatory compliance and industry best practices

Day 1: CUI Fundamentals, Mechanisms, and Inspection

Session 1: Introduction to CUI (8:00 AM - 10:00 AM)

Understanding CUI Phenomena

Foundation of corrosion under insulation:

CUI Definition and Scope:

Corrosion occurring on external surfaces beneath insulation

Hidden damage difficult to detect

Major integrity threat across all industries

Estimated costs: billions annually worldwide

Statistics: 40-60% of piping maintenance costs

Historical catastrophic failures and incidents

Types of CUI:

Corrosion Under Insulation (CUI): general atmospheric corrosion

Stress Corrosion Cracking Under Insulation (CUISCC)

Microbiologically Influenced Corrosion (MIC)

Chloride-induced pitting and SCC

External corrosion on hot and cold systems

Susceptible Equipment:

Carbon steel piping and vessels

Stainless steel systems: 304, 316 grades

Operating temperature range: -4°C to 175°C (critical zone)

Cyclic operations and thermal cycling

Equipment subject to weather exposure

Deadlegs and infrequently used lines

Economic Impact:

Maintenance and repair costs

Production losses from shutdowns

Safety incidents and environmental releases

Insurance and liability costs

Replacement versus repair decisions

Industry statistics and benchmarks

Session 2: CUI Mechanisms and Contributing Factors (10:15 AM - 12:30 PM)

How CUI Occurs

Understanding corrosion mechanisms:

Water Ingress Pathways:

Damaged or degraded insulation jacketing

Penetrations and terminations: flanges, supports

Improper sealing at equipment interfaces

Missing or damaged vapor barriers

Condensation from temperature cycling

Rain, spray, and deluge system water

Steam tracing leaks

Corrosion Chemistry:

Atmospheric corrosion accelerated by insulation

Electrolyte formation under insulation

Oxygen availability and differential aeration

Chloride contamination from insulation or environment

pH changes from insulation leachates

Temperature cycling effects on corrosion rates

Material Susceptibility:

Carbon steel: general corrosion, thinning

300-series stainless steel: chloride SCC

Low-alloy steels: hydrogen embrittlement risks

Aluminum: caustic corrosion from certain insulations

Copper alloys: stress corrosion cracking

Temperature Effects:

Critical temperature range: -4°C to 175°C

Maximum CUI activity: 50-150°C

Condensation zone below dew point

Thermal cycling acceleration

Hot-cold interface areas

Seasonal temperature variations

Insulation System Factors:

Insulation material selection

Jacketing material and condition

Vapor barrier effectiveness

Sealant and mastic quality

Installation workmanship

Maintenance and repair quality

Age and service history

Session 3: Risk Assessment and Prioritization (1:30 PM - 3:30 PM)

Identifying High-Risk Areas

Implementing risk-based approaches:

Risk Factors:

Operating temperature (susceptibility zone)

Cyclic versus continuous operation

Age of insulation system

Geographic location and climate

Insulation type and condition

Damage history and repair records

Material of construction

Likelihood Assessment:

Inspection history and findings

Previous corrosion damage

Design and installation quality

Operating conditions severity

Maintenance practices

Environmental exposure

Age and service life

Consequence Evaluation:

Safety hazards: flammable, toxic fluids

Environmental impact potential

Production criticality

Replacement cost and complexity

Accessibility for repair

Redundancy availability

Regulatory implications

Risk-Based Inspection (RBI):

API 580/581 methodology application

Damage mechanism identification

Probability of failure calculations

Consequence of failure assessment

Risk matrix development

Inspection prioritization

Resource optimization

High-Risk Locations:

Flanges, valves, and fittings

Pipe supports and attachments

Termination points at equipment

Deadlegs and infrequently used lines

Areas exposed to water spray

Damaged insulation jacketing

Low points and drainage areas

Session 4: Inspection and Detection Techniques (3:45 PM - 5:30 PM)

Finding Hidden Corrosion

Mastering inspection methods:

Visual Inspection:

External insulation condition assessment

Jacketing damage and deterioration

Staining, rust bleeding, and bulging

Missing or damaged insulation

Wet insulation indicators

Sealant and mastic condition

Systematic documentation methods

Conventional NDT Methods:

Ultrasonic thickness testing (UTT): most common

Profile radiography: through insulation

Real-time radiography (RTR)

Magnetic flux leakage (MFL)

Infrared thermography: moisture detection

Neutron backscatter: moisture mapping

Advanced Inspection Technologies:

Pulsed eddy current (PEC): through insulation screening

Long-range ultrasonic testing (LRUT)

Guided wave technology

Electromagnetic acoustic transducers (EMAT)

Acoustic emission for active corrosion

Digital radiography and computed tomography

Inspection Strategy Development:

Full insulation removal versus partial

Screening techniques for large populations

Focused inspection at high-risk areas

Access and scaffolding considerations

Production shutdown coordination

Cost-benefit analysis of methods

Inspection Frequency:

API 570 and API 510 guidelines

Initial baseline inspection

Routine inspection intervals: 3-5 years typical

Adjusted based on findings and risk

Seasonal considerations

Opportunistic inspection during maintenance

Day 2: Prevention, Mitigation, and Management Programs

Session 5: CUI Prevention Strategies (8:00 AM - 10:00 AM)

Preventing CUI Through Design

Implementing prevention strategies:

Design Considerations:

Insulation system specification: materials and design

Jacketing selection: aluminum, stainless steel

Vapor barrier requirements

Drainage design and low-point elimination

Support design minimizing insulation penetrations

Termination design at equipment interfaces

Access provisions for future inspection

Insulation Material Selection:

Closed-cell versus open-cell insulation

Calcium silicate: traditional but moisture-susceptible

Mineral wool: moderate moisture resistance

Cellular glass: excellent moisture resistance

Aerogel: advanced low-conductivity option

Non-leachable chloride requirements (<50 ppm)

Hydrophobic coatings and treatments

Jacketing and Vapor Barriers:

Aluminum jacketing: most common

Stainless steel jacketing: severe environments

PVC and polymer jacketing

Vapor barrier membranes

Sealants and mastics: silicone, polyurethane

Banding and fastening systems

Weather barrier effectiveness

Protective Coatings:

High-performance coatings under insulation

Thermal spray aluminum (TSA): excellent protection

High-build epoxies and polyurethanes

Inorganic zinc primers

Surface preparation requirements (SSPC-SP standards)

Application and curing conditions

Inspection and quality control

Session 6: Mitigation and Repair Strategies (10:15 AM - 12:30 PM)

Managing Existing CUI

Implementing mitigation approaches:

Insulation Removal Decisions:

When to remove versus retain insulation

Cost-benefit analysis of removal

Operational impact considerations

Energy loss calculations

Personnel safety during removal

Disposal and environmental considerations

Coating Application on Existing Systems:

Surface preparation challenges

Blast cleaning in place

Coating selection for existing equipment

Application methods and access

Cure time and temperature requirements

Quality assurance and inspection

Insulation Replacement:

Upgrade to improved systems

Modern materials and designs

Jacketing and vapor barrier improvements

Installation quality control

Documentation and as-built records

Warranty and performance guarantees

Operational Mitigation:

Temperature management strategies

Minimizing thermal cycling

Steam tracing optimization

Water spray avoidance

Drainage improvement

Regular inspection and maintenance

Session 7: CUI Management Programs (1:30 PM - 3:30 PM)

Developing Comprehensive Programs

Creating CUI management systems:

Program Elements:

Policy and accountability definition

Asset inventory and data management

Risk assessment and prioritization

Inspection planning and execution

Mitigation strategy implementation

Performance metrics and KPIs

Continuous improvement processes

Data Management:

Insulated equipment inventory

Isometric drawings with CUI data

Inspection history and findings database

Thickness measurement trending

Risk ranking and prioritization

Work order integration

Document management systems

Inspection Planning:

Master inspection plans

Annual inspection schedules

Resource allocation and budgeting

Contractor qualification and management

Quality assurance programs

Documentation requirements

Regulatory compliance verification

Industry Standards and Guidelines:

API 570: Piping Inspection Code

API 510: Pressure Vessel Inspection

NACE SP0198: Control of CUI

ASTM C 795: Thermal Insulation Materials

EFC Publication 55: CUI Guidelines

ISO 12944: Protective paint systems

Regulatory Compliance:

OSHA PSM mechanical integrity

EPA RMP requirements

Insurance inspection requirements

Jurisdictional regulations

Environmental protection standards

Recordkeeping and documentation

Session 8: Case Studies and Best Practices (3:45 PM - 5:30 PM)

Learning from Industry Experience

Analyzing real-world applications:

Catastrophic CUI Failures:

Refinery piping rupture incidents

Pressure vessel failures from CUI

Stainless steel SCC under insulation

Environmental releases and consequences

Safety incidents and fatalities

Economic impact analysis

Root cause findings and lessons

Successful CUI Programs:

Industry benchmark programs

Best practice implementations

Technology adoption success stories

Cost savings and ROI documentation

Organizational change management

Culture and awareness development

Technology Applications:

Pulsed eddy current screening programs

Infrared thermography campaigns

Protective coating performance

Advanced insulation system implementations

Robotics and drones for inspection

Digital transformation and analytics

Interactive Workshop:

Participant case study presentations

Group problem-solving exercises

CUI program development workshop

Inspection planning exercise

Cost-benefit analysis practice

Action plan development

Key Takeaways and Action Planning:

Summary of critical learning points

Implementation roadmap development

Resource requirements identification

Quick wins versus long-term strategies

Networking and knowledge sharing

Post-course support and resources

Course Deliverables

Participants Receive:

Comprehensive CUI technical manual (200+ pages)

API and NACE standards excerpts

Inspection procedure templates

Risk assessment worksheets

Case study compilation

NDT technology comparison charts

Material selection guides

Professional certificate of completion

Access to online resource library

Vendor and technology directory

Interactive Learning:

Insulation system component samples

Corroded pipe section examination

NDT equipment demonstrations

Coating application videos

Software tools for risk assessment

Group exercises and discussions

Q&A with industry experts

Why This Masterclass Is Essential

Key Benefits:

Prevent catastrophic equipment failures

Reduce unplanned shutdowns and production losses

Optimize inspection and maintenance spending

Enhance safety and environmental performance

Build organizational CUI expertise

Achieve regulatory compliance

Implement industry best practices

Critical Statistics:

CUI responsible for 40-60% of piping maintenance costs

60% of insulated assets show some CUI damage

Average repair cost: $10,000-$100,000 per location

Catastrophic failures costing millions

Growing problem with aging infrastructure

ROI:

Early detection prevents major failures

Optimized inspection reduces costs

Proactive prevention extends asset life

Avoided production losses

Reduced safety and environmental incidents

Lower insurance premiums

Keywords: corrosion under insulation, CUI inspection, CUI prevention, insulation corrosion, pulsed eddy current, ultrasonic testing, CUI management, API 570, NACE SP0198, external corrosion, insulated piping inspection, risk-based inspection, thermal spray aluminum, protective coatings