Engineering Materials for Buildings and Bridges

$5500.00

Engineering Materials for Buildings and Bridges: 5-Day Professional Course

Course Overview

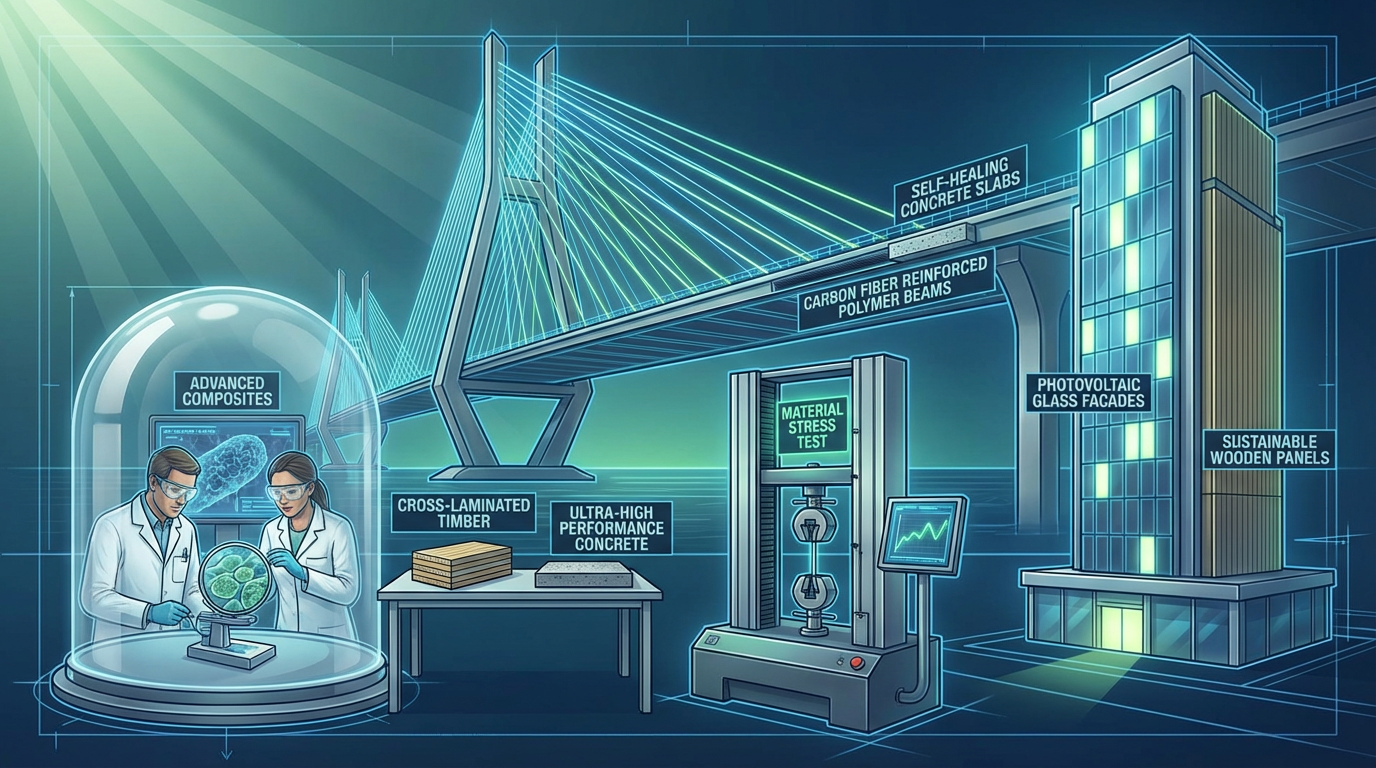

This comprehensive 5-day training program provides in-depth knowledge of engineering materials used in building and bridge construction, covering material properties, behavior, selection criteria, testing methods, and performance requirements. Designed for civil engineers, structural engineers, architects, construction managers, inspectors, and material engineers, this course emphasizes material science fundamentals, practical applications, durability considerations, and emerging technologies for sustainable infrastructure development.

Target Audience: Civil/structural engineers, architects, construction managers, materials engineers, quality control professionals, bridge engineers, building designers, project managers, and inspectors working with construction materials.

Day 1: Fundamentals of Engineering Materials & Steel

Morning Session: Material Science Principles (9:00 AM - 12:00 PM)

Engineering Material Fundamentals:

Understanding atomic structure, crystalline materials, material properties, and behavior under stress essential for selecting and specifying construction materials.

Core Concepts:

Atomic bonding and material structure

Crystalline and amorphous materials

Material properties: mechanical, physical, thermal, chemical

Stress-strain relationships and elastic behavior

Yield strength, ultimate strength, and ductility

Modulus of elasticity and stiffness

Poisson’s ratio and material deformation

Hardness, toughness, and fracture mechanics

Fatigue and creep behavior

Thermal expansion and conductivity

Durability and environmental resistance

Material testing standards (ASTM, BS, EN, ISO)

Material selection criteria for structures

Sustainability and life-cycle assessment

Emerging materials and nanotechnology applications

Afternoon Session: Structural Steel Materials (1:00 PM - 5:00 PM)

Steel for Buildings and Bridges:

Mastering structural steel grades, properties, manufacturing processes, connections, and applications in modern construction with emphasis on high-strength and weathering steels.

Steel Technology:

Steel manufacturing: blast furnace, basic oxygen, electric arc processes

Carbon steel composition and microstructure

Structural steel grades: ASTM A36, A572, A992, A588

High-strength low-alloy (HSLA) steels

Weathering steel (Corten) properties and applications

Heat treatment processes: annealing, normalizing, quenching, tempering

Mechanical properties: yield strength, tensile strength, elongation

Charpy V-notch impact testing and toughness

Weldability and carbon equivalent

Corrosion mechanisms and protection methods

Galvanizing, painting, and coating systems

Structural steel shapes: wide flange, channels, angles, tubes

Connection types: bolted, welded, riveted

Fatigue considerations in bridges

Steel testing: tensile test, hardness, chemical analysis

Quality control and mill certifications

Laboratory Session: Steel specimen testing demonstrations and metallurgical examination

Day 2: Concrete Materials & Technology

Morning Session: Cement, Aggregates & Admixtures (9:00 AM - 12:00 PM)

Concrete Constituent Materials:

Understanding cement types, aggregate properties, supplementary cementitious materials, and chemical admixtures that determine concrete performance and durability.

Material Components:

Portland cement types and applications (Type I-V)

Cement hydration and heat generation

Supplementary Cementitious Materials (SCMs): fly ash, slag, silica fume

Natural pozzolans and metakaolin

Aggregate types: natural, crushed, manufactured, recycled

Aggregate gradation and particle size distribution

Aggregate shape, texture, and angularity effects

Deleterious materials in aggregates

Alkali-aggregate reactivity (AAR) and mitigation

Water quality and impurities

Chemical admixtures: water reducers, superplasticizers, retarders, accelerators

Air-entraining admixtures for freeze-thaw resistance

Shrinkage reducers and corrosion inhibitors

Fiber reinforcement: steel, synthetic, glass

Material testing standards and specifications

Afternoon Session: Concrete Properties & Performance (1:00 PM - 5:00 PM)

Fresh and Hardened Concrete:

Evaluating concrete workability, strength development, durability characteristics, and long-term performance for building and bridge applications.

Concrete Performance:

Fresh concrete properties: workability, slump, flow

Setting time and temperature effects

Compressive strength development and testing (ASTM C39)

Tensile and flexural strength characteristics

Modulus of elasticity and Poisson’s ratio

Creep and shrinkage behavior

Permeability and transport properties

Freeze-thaw resistance mechanisms

Chloride penetration and corrosion protection

Sulfate attack and chemical resistance

Alkali-silica reaction (ASR) mitigation

Carbonation and durability

High-performance concrete (HPC) for bridges

Self-consolidating concrete (SCC) applications

Ultra-high-performance concrete (UHPC) technology

Lightweight and heavyweight concrete

Quality control testing programs

Workshop: Concrete mix design exercise for bridge deck application

Day 3: Reinforcement, Prestressing & Composite Materials

Morning Session: Reinforcement Materials (9:00 AM - 12:00 PM)

Reinforcing Steel and Alternatives:

Understanding reinforcing bar grades, properties, corrosion protection, and alternative reinforcement materials including fiber-reinforced polymers (FRP) for durable structures.

Reinforcement Types:

Conventional steel reinforcement: grades 40, 60, 75, 80

Deformation patterns and bond characteristics

Epoxy-coated reinforcing bars (ECR)

Galvanized reinforcement for corrosion protection

Stainless steel reinforcement: austenitic and duplex grades

Carbon steel vs. stainless steel life-cycle costs

Glass Fiber Reinforced Polymer (GFRP) bars

Carbon Fiber Reinforced Polymer (CFRP) bars

Basalt Fiber Reinforced Polymer (BFRP) bars

FRP material properties: tensile strength, modulus, rupture strain

Design considerations for FRP reinforcement (ACI 440)

Corrosion resistance and durability benefits

Welded wire reinforcement (WWR)

Bar supports and positioning accessories

Testing: tensile testing, bend tests, bond tests

Quality control and material certifications

Afternoon Session: Prestressing Systems & Composite Materials (1:00 PM - 5:00 PM)

Advanced Structural Materials:

Exploring prestressing steel, post-tensioning systems, and composite materials that enable longer spans, reduced sections, and innovative structural solutions.

Prestressing Technology:

Prestressing principles and advantages

Prestressing strand: 7-wire, grades 250, 270 ksi

Prestressing wire and bars

Relaxation characteristics and losses

Pre-tensioning systems and procedures

Post-tensioning systems: bonded and unbonded

Anchorage systems and hardware

Ducts, grout, and corrosion protection

External prestressing for bridges

Carbon Fiber Reinforced Polymer (CFRP) prestressing

Structural composite materials: steel-concrete, FRP-concrete

Sandwich panels and hybrid systems

Composite bridge decks

Fiber Metal Laminates (FML)

Testing and quality assurance

Innovation in composite bridge construction

Case Studies: Prestressed concrete bridges and composite structure applications

Day 4: Masonry, Timber & Protective Systems

Morning Session: Masonry Materials & Systems (9:00 AM - 12:00 PM)

Masonry Construction Materials:

Understanding clay brick, concrete masonry units, mortar, grout, and reinforcement for load-bearing and veneer masonry in building construction.

Masonry Components:

Clay brick manufacturing and classification

Concrete masonry units (CMU): hollow and solid

Brick grades and weather resistance (ASTM C216, C62)

CMU strength grades and applications

Architectural vs. structural masonry

Mortar types: M, S, N, O, K and selection criteria

Mortar materials: cement, lime, sand, admixtures

Grout for reinforced masonry

Masonry reinforcement: joint reinforcement, rebar

Mechanical properties: compressive strength, flexural strength

Bond strength and prism testing

Moisture resistance and efflorescence

Thermal properties and insulation value

Fire resistance ratings

Durability and freeze-thaw resistance

Quality control testing requirements

Afternoon Session: Timber & Wood Products (1:00 PM - 5:00 PM)

Structural Wood Materials:

Exploring solid timber, engineered wood products, and timber connections for modern building and bridge construction with emphasis on sustainability.

Wood Technology:

Wood structure: grain, growth rings, moisture content

Softwood vs. hardwood species for construction

Lumber grading: visual and machine stress-rated (MSR)

Design values and adjustment factors

Dimensional lumber sizes and standards

Glued-laminated timber (glulam) manufacturing and applications

Cross-laminated timber (CLT) technology

Laminated Veneer Lumber (LVL) and Parallel Strand Lumber (PSL)

I-joists and engineered floor systems

Plywood and oriented strand board (OSB)

Mass timber construction for multi-story buildings

Timber bridges and pedestrian structures

Moisture content effects on properties

Wood preservation treatments: pressure-treated, fire retardants

Connections: nails, screws, bolts, metal connectors

Durability and decay resistance

Sustainable forestry and carbon sequestration

Testing: moisture meters, stress grading, strength testing

Site Visit/Virtual Tour: Mass timber building or timber bridge facility

Day 5: Protective Materials, Testing & Material Selection

Morning Session: Coatings, Sealants & Waterproofing (9:00 AM - 12:00 PM)

Protective Material Systems:

Understanding coatings, sealants, membranes, and waterproofing systems that protect structures from moisture, chemicals, and environmental deterioration.

Protection Systems:

Paint and coating systems: primers, intermediates, topcoats

Epoxy coatings for concrete and steel

Polyurethane and polyurea coatings

Zinc-rich primers and galvanic protection

Intumescent fire-protective coatings

Anti-graffiti and easy-clean coatings

Joint sealants: silicone, polyurethane, polysulfide

Sealant properties: movement capability, adhesion, durability

Expansion joint systems for bridges and buildings

Waterproofing membranes: sheet and liquid-applied

Below-grade waterproofing systems

Plaza deck and parking structure membranes

Bridge deck waterproofing materials

Vapor barriers and air barriers

Geotextiles and geomembranes

Quality control: adhesion testing, thickness measurement

Application requirements and surface preparation

Life expectancy and maintenance requirements

Afternoon Session: Material Testing & Quality Assurance (1:00 PM - 3:30 PM)

Testing Protocols:

Implementing comprehensive material testing programs, interpretation of results, and quality assurance procedures ensuring materials meet project specifications.

Testing Methods:

Destructive vs. non-destructive testing

Steel testing: tensile, hardness, impact, chemical analysis

Concrete testing: compression, split-cylinder, flexural

Aggregate testing: gradation, LA abrasion, specific gravity

Cement testing: fineness, setting time, soundness

Non-destructive testing: rebound hammer, ultrasonic, GPR

Core drilling and evaluation procedures

Welding inspection and testing

Material sampling procedures and protocols

Laboratory accreditation (AASHTO, ASTM)

Statistical analysis and acceptance criteria

Material certifications and mill test reports

Quality management systems (ISO 9001)

Material traceability and documentation

Field testing vs. laboratory testing

Reporting requirements and interpretation

Closing Session: Material Selection & Sustainable Materials (3:30 PM - 5:00 PM)

Integrated Material Selection:

Developing systematic approaches to material selection considering structural requirements, durability, sustainability, cost, and life-cycle performance.

Selection Framework:

Multi-criteria decision analysis for materials

Performance-based specifications

Structural performance requirements

Durability and service life prediction

Environmental exposure classification

Cost analysis: initial costs vs. life-cycle costs

Sustainability metrics: embodied energy, carbon footprint

Green building materials and certifications (LEED, BREEAM)

Recycled and reclaimed materials

Low-carbon concrete and supplementary materials

Bio-based materials and innovations

Circular economy principles

Material compatibility considerations

Constructability and availability

Maintenance and repair considerations

Future trends: self-healing materials, smart materials, nanomaterials

Capstone Project:

Teams specify complete material package for building or bridge project including structural materials, protective systems, and testing program with technical justification and sustainability assessment.

Course Conclusion:

Emerging material technologies and research

Professional certifications: materials testing, inspection

Industry resources and technical organizations

Q&A with materials engineering experts

Certificate of Completion award (35 PDH/CEU credits)

Learning Outcomes

Participants will be able to:

Understand fundamental material science principles and behavior

Select appropriate materials for specific structural applications

Specify testing requirements and interpret results correctly

Evaluate material properties for durability and performance

Design with diverse materials: steel, concrete, masonry, timber

Implement quality assurance programs for material acceptance

Apply protective systems for long-term structure preservation

Consider sustainability in material selection decisions

Solve material-related problems in construction projects

Stay current with emerging material technologies

Course Materials Included

Comprehensive engineering materials handbook

Material property tables and reference data

ASTM and AASHTO testing standards excerpts

Material selection decision matrices

Quality control checklists and forms

Case study collection with failure analysis

Certificate of Completion (35 PDH/CEU credits)

Access to online materials resource library

Course Delivery Methods

Technical lectures with multimedia presentations

Laboratory demonstrations and testing exercises

Material samples and physical examination

Video case studies and construction footage

Group workshops and problem-solving exercises

Site visits or virtual facility tours

Prerequisites

Bachelor’s degree in civil/structural engineering, architecture, or related field, OR minimum 3 years construction experience. Basic understanding of structural mechanics and material behavior recommended.

Keywords: engineering materials course, construction materials, structural steel, concrete technology, building materials, bridge materials, material testing, reinforcement materials, prestressing steel, composite materials, masonry materials, timber engineering, material selection, protective coatings, sustainable materials, material properties, quality assurance, ASTM standards, construction specifications, durability engineering, material science training