Drilling Engineering Fundamentals

$5500.00

Drilling Engineering Fundamentals: 5-Day Professional Training Course

Course Overview

This comprehensive 5-day drilling engineering fundamentals program delivers essential knowledge and practical skills for drilling operations in the oil and gas industry. Tailored for professionals in the Kingdom of Saudi Arabia (KSA), Oman, GCC countries, and Africa, this course covers drilling theory, operational practices, wellbore design, and regional-specific challenges in onshore and offshore drilling environments.

Target Audience

Drilling engineers and supervisors

Petroleum engineers transitioning to drilling operations

Wellsite supervisors and rig personnel

Operations geologists and reservoir engineers

HSE professionals in drilling operations

Engineering graduates entering the drilling industry

Technical staff from Saudi Aramco, PDO, ADNOC, and African operators

Day 1: Introduction to Drilling Engineering

Morning Session: Drilling Fundamentals

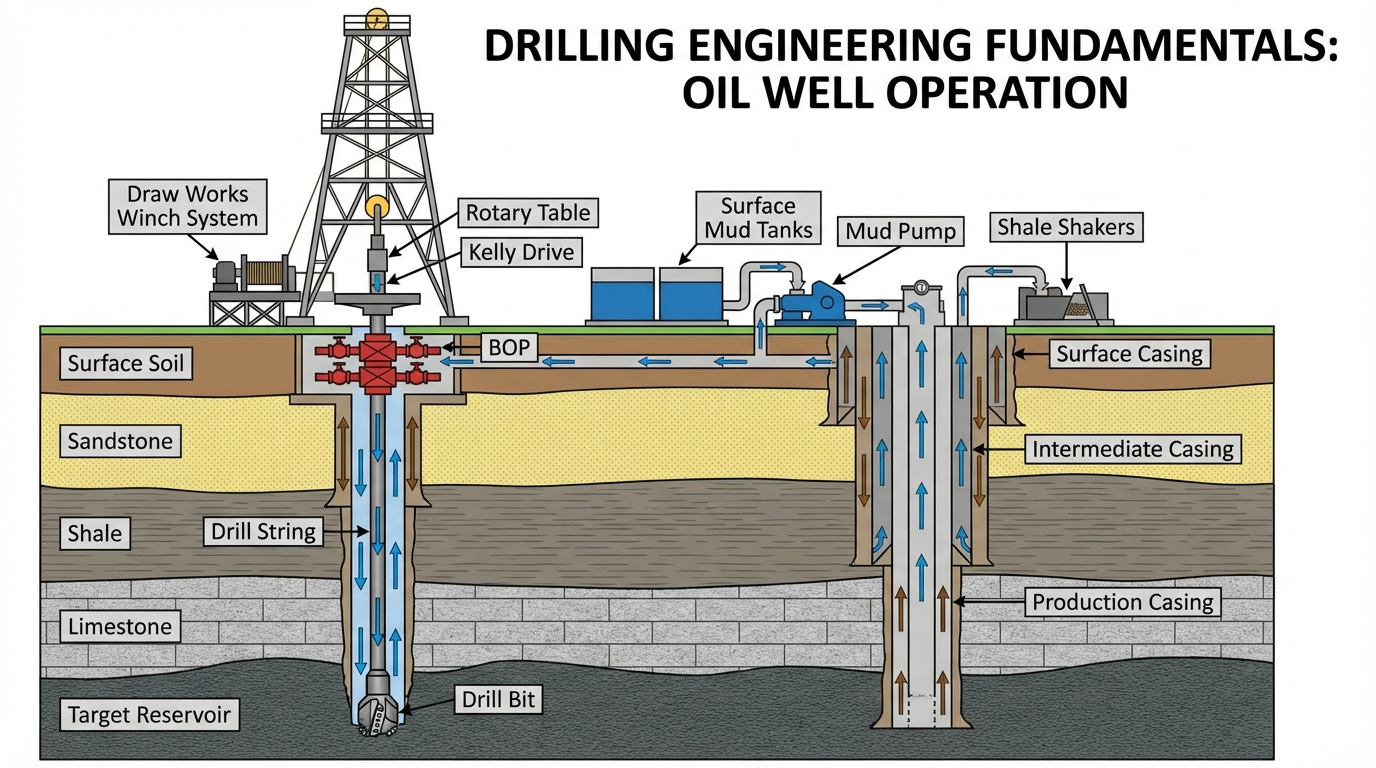

Module 1.1: Oil and Gas Well Drilling Overview

History and evolution of rotary drilling

Drilling rig types: land rigs, jack-ups, semi-submersibles, drillships

Rig components and classification systems

Regional drilling landscape: KSA’s Ghawar and Safaniyah fields, Oman’s interior basins, GCC offshore operations

African drilling environments: deepwater West Africa, North African deserts, East African rift systems

Module 1.2: Drilling Rig Systems and Equipment

Hoisting system: drawworks, crown block, traveling block, drilling line

Rotating system: rotary table, top drive, kelly drive mechanisms

Circulation system: mud pumps, standpipe, rotary hose, swivel

Power generation and distribution systems

Blowout prevention equipment (BOP) and well control systems

Automated drilling systems and rig instrumentation

Afternoon Session: Well Planning Fundamentals

Module 1.3: Well Planning Process

Exploration, appraisal, and development drilling objectives

Well trajectory design: vertical, directional, horizontal, and ERD wells

Subsurface data analysis and geological considerations

Pore pressure and fracture gradient prediction

Drilling hazards in the Middle East and Africa: salt formations, H2S, high-pressure zones

Module 1.4: Drilling Program Development

Well design philosophy and safety factors

Casing and tubing design principles

Drilling fluids selection criteria

Cementing program planning

Time and cost estimation

Regulatory requirements: KSA DGR, Oman MoG, African petroleum directorates

Day 2: Drilling Fluids and Hydraulics

Morning Session: Drilling Fluids Technology

Module 2.1: Drilling Mud Functions and Types

Primary functions: cuttings removal, wellbore stability, pressure control

Water-based muds (WBM): bentonite, polymer, salt-saturated systems

Oil-based muds (OBM) and synthetic-based muds (SBM)

Special fluids for challenging formations in GCC and Africa

Environmental regulations and mud disposal practices

Drilling fluid additives and their functions

Module 2.2: Mud Properties and Testing

Density (mud weight) measurement and control

Viscosity and rheological properties

Filtration and wall-building characteristics

API standard testing procedures

pH, alkalinity, and chemical composition

Contamination identification and treatment

Field testing and quality control protocols

Afternoon Session: Drilling Hydraulics

Module 2.3: Hydraulics Optimization

Pressure losses in the circulating system

Annular velocity calculations

Equivalent circulating density (ECD) management

Surge and swab pressures

Bit hydraulics and nozzle selection

Hydraulic horsepower optimization

Managed pressure drilling (MPD) concepts

Module 2.4: Hole Cleaning and Cuttings Transport

Cuttings transport mechanics in vertical and deviated wells

Critical flow rate determination

Hole cleaning challenges in extended reach drilling

Barite sagging and bed formation prevention

Special considerations for Middle East carbonates and African shales

Day 3: Drilling Operations and Directional Drilling

Morning Session: Drilling Operations

Module 3.1: Drilling Operations Sequence

Rig-up and rig mobilization procedures

Spudding and conductor installation

Surface hole, intermediate, and production hole sections

Tripping operations: trip in, trip out procedures

Connections and drilling break operations

Stuck pipe prevention and remedial actions

Fishing operations and tools

Module 3.2: Drill String Design and BHA

Drill pipe specifications and grades

Heavyweight drill pipe and drill collars

Bottom hole assembly (BHA) configuration

Stabilizers, reamers, and hole openers

Drilling jars and shock subs

Torque and drag analysis

Fatigue and failure prevention

Afternoon Session: Directional Drilling

Module 3.3: Directional Drilling Fundamentals

Directional drilling applications and benefits

Well trajectory planning and survey calculations

Kickoff point (KOP) determination

Build-up, drop-off, and turn sections

Horizontal drilling in Saudi Arabian tight reservoirs

Maximum reservoir contact (MRC) wells in Oman

Multilateral wells and complex trajectories

Module 3.4: Directional Drilling Tools and Technology

Mud motors and positive displacement motors (PDM)

Rotary steerable systems (RSS)

Measurement while drilling (MWD) and logging while drilling (LWD)

Survey tools and accuracy considerations

Electromagnetic and gyroscopic survey methods

Geosteering in thin reservoirs

Real-time drilling optimization

Day 4: Cementing, Casing, and Well Control

Morning Session: Casing and Cementing

Module 4.1: Casing Design Principles

Casing functions and program design

Load analysis: burst, collapse, and tension

Casing grades and connections

Casing running procedures

Centralizers, scratchers, and accessories

Wellhead equipment and Christmas tree systems

Regulatory requirements in KSA, Oman, GCC, and Africa

Module 4.2: Cementing Operations

Cement slurry design and additives

Primary cementing objectives and techniques

Cement job design: lead, tail, and spacer fluids

Displacement efficiency and mud removal

Cement evaluation: CBL, VDL, ultrasonic tools

Remedial cementing: squeeze jobs

High-temperature cementing in deep GCC wells

Lost circulation management during cementing

Afternoon Session: Well Control

Module 4.3: Well Control Fundamentals

Pressure control concepts and kick detection

BOP stack configuration and testing

Primary, secondary, and tertiary well control barriers

Kick warning signs and early detection

Well control procedures: shut-in and circulation methods

Driller’s method and wait-and-weight method

Kill sheet calculations and procedures

Module 4.4: Well Control Scenarios

Gas kicks in offshore GCC operations

H2S drilling in Saudi Arabia and Oman sour gas fields

High-pressure/high-temperature (HPHT) well control

Shallow gas hazards in African offshore drilling

Underground blowouts and well intervention

Well control equipment maintenance

HSE considerations and emergency response

Day 5: Advanced Topics and Practical Applications

Morning Session: Drilling Challenges and Solutions

Module 5.1: Formation Evaluation While Drilling

LWD technology and applications

Resistivity, porosity, and density measurements

Formation pressure testing while drilling

Real-time geological steering

Integration with reservoir engineering

Case studies from Oman’s Khazzan tight gas field

Module 5.2: Drilling Problems and Solutions

Lost circulation in fractured Middle East carbonates

Differential sticking mechanisms and prevention

Wellbore instability in reactive shales

Salt and shale creep formations

Torque and drag in extended reach wells

Drill string vibrations and mitigation

Borehole quality and rugosity management

Afternoon Session: Emerging Technologies and Case Studies

Module 5.3: Advanced Drilling Technologies

Automated drilling systems and machine learning

Casing drilling and dual-gradient drilling

Underbalanced drilling (UBD) applications

Coiled tubing drilling operations

Drilling optimization and performance metrics

Digital oilfield and remote operations centers

Saudi Aramco’s unconventional drilling programs

Geothermal drilling fundamentals

Module 5.4: Regional Case Studies and Workshop

Saudi Arabia: Maximum reservoir contact wells in Shaybah field

Oman: Tight gas drilling in Khazzan and Makarem fields

UAE: Offshore HPHT sour gas drilling challenges

Kuwait: Heavy oil horizontal drilling in Burgan field

Africa: Deepwater drilling in Angola and Mozambique

North Africa: Desert drilling optimization in Algeria and Libya

Interactive drilling problem-solving exercises

Drilling cost optimization strategies

Q&A session and course conclusion

Course Learning Outcomes

Upon completion, participants will:

Understand fundamental drilling engineering principles and calculations

Design basic drilling programs for various well types

Analyze drilling fluid properties and hydraulics optimization

Apply directional drilling concepts and trajectory planning

Implement well control procedures and kick management

Evaluate drilling challenges specific to Middle East and African operations

Utilize modern drilling technologies and optimization techniques

Regional Focus: KSA, Oman, GCC & Africa

Kingdom of Saudi Arabia: Addressing challenges in massive carbonate reservoirs, unconventional tight gas development, sour gas drilling, and maximum reservoir contact drilling techniques deployed by Saudi Aramco.

Oman: Covering tight gas formations, complex fault structures, high-angle wells in interior basins, and Petroleum Development Oman (PDO) best practices.

GCC Region: Including ADNOC’s offshore sour gas operations, Qatar’s carbonate reservoirs, Kuwait’s heavy oil challenges, and Bahrain’s tight oil drilling.

Africa: Encompassing deepwater West Africa operations, North African desert drilling, East African rift exploration, and emerging plays in Mozambique, Senegal, and Uganda.

Training Methodology

Instructor-led technical presentations

Hands-on calculations and engineering exercises

Video demonstrations of rig operations

Software simulations for drilling hydraulics

Real-world case study analysis

Interactive problem-solving sessions

Field trip opportunities (where available)

Comprehensive course materials and reference guides

Duration: 5 days (40 training hours)

Delivery: Classroom, online, or hybrid format

Language: English (Arabic support available)

Certification: Professional development certificate

Keywords: drilling engineering training, oil and gas drilling course KSA, drilling fundamentals Oman, GCC drilling operations, African drilling training, directional drilling Middle East, well control training, drilling fluids course, petroleum drilling engineering, Saudi Aramco drilling, PDO drilling practices, offshore drilling GCC