Corrosion failure modes and materials of construction in nitric acid plants

$5500.00

Corrosion Failure Modes and Materials of Construction in Nitric Acid Plants: 5-Day Specialized Training Course

Course Overview

This intensive 5-day nitric acid plant corrosion training provides specialized knowledge of corrosion mechanisms, failure modes, and materials selection for nitric acid manufacturing facilities. Designed for materials engineers, corrosion specialists, plant engineers, and maintenance professionals.

Target Audience: Materials engineers, corrosion specialists, integrity engineers, plant engineers, maintenance managers, metallurgists, and technical professionals in nitric acid facilities.

Course Objectives:

Understand corrosion mechanisms in nitric acid environments

Master materials selection for different plant sections

Identify common failure modes and root causes

Implement corrosion prevention strategies

Apply inspection and integrity management techniques

Day 1: Nitric Acid Process and Corrosion Fundamentals

Morning Session: Process Overview

Understanding the Environment

Foundation of nitric acid manufacturing:

Process Description:

Ammonia oxidation (Ostwald process)

Catalytic oxidation: ammonia to NO (850-950°C)

NO oxidation to NO₂

Absorption in water: forming dilute and concentrated acid

Plant capacities: 500-2000 MTPD

Single, dual, and triple pressure processes

Nitric Acid Concentrations:

Weak acid: 50-70% HNO₃

Concentrated acid: 98-99% HNO₃

Azeotropic concentration: 68.4%

Concentration methods: extractive distillation

Temperature effects on corrosivity

Corrosive Species:

Nitric acid (HNO₃): oxidizing acid

Nitrogen oxides: NOx, NO, NO₂

Nitrous acid (HNO₂): highly corrosive

Dissolved oxygen effects

Velocity and erosion-corrosion

Afternoon Session: Corrosion Mechanisms

How Corrosion Occurs

Understanding corrosion fundamentals:

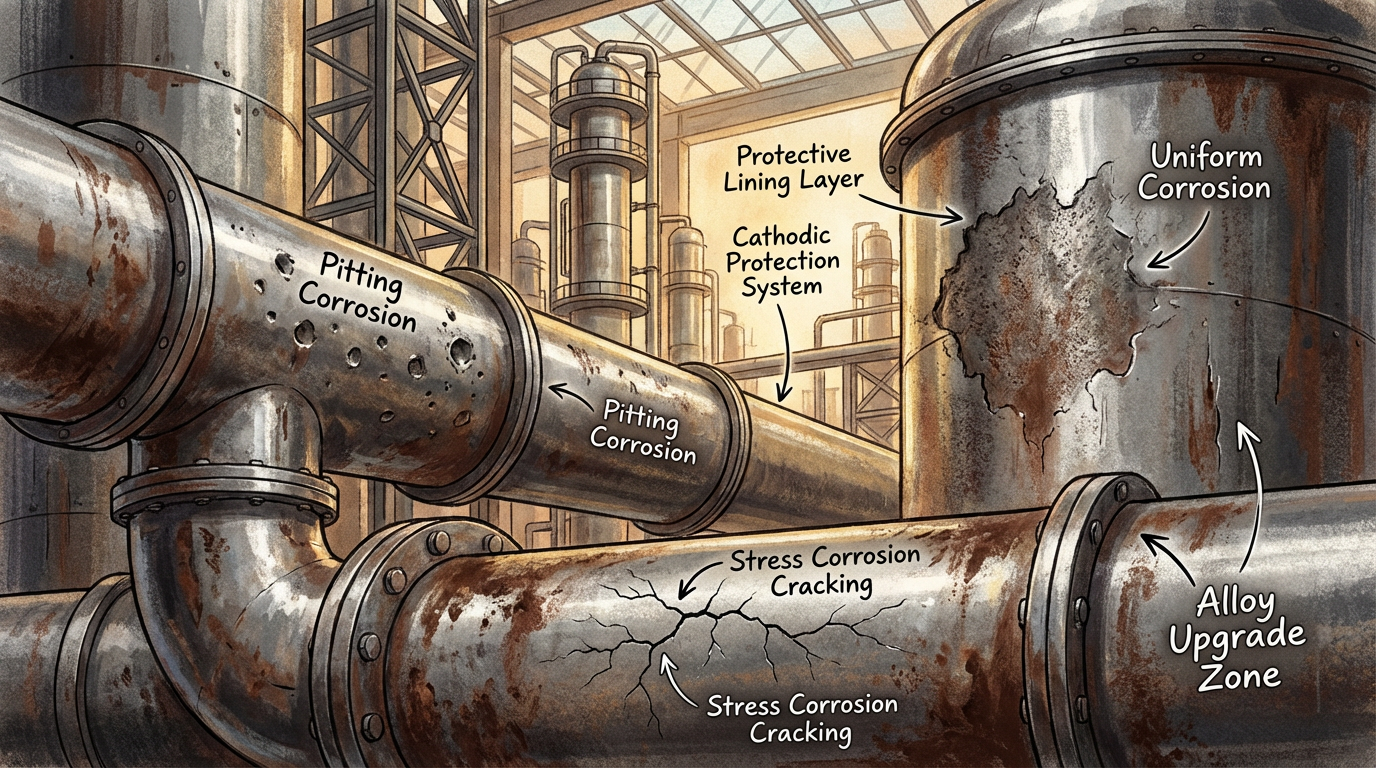

General Corrosion:

Uniform metal dissolution

Passivity and passive film formation

Passivity breakdown conditions

Temperature and concentration effects

Localized Corrosion:

Pitting corrosion: chloride influence critical

Crevice corrosion in flanges

Selective grain boundary attack

Deposit-induced corrosion

Under-insulation corrosion (CUI)

Intergranular Corrosion (IGC):

Sensitization of stainless steels

Grain boundary chromium depletion

Weld heat-affected zones (HAZ)

Carbide precipitation mechanisms

Prevention through material selection

Stress Corrosion Cracking (SCC):

Chloride SCC in austenitic stainless steels

Transgranular crack morphology

Required conditions: stress, environment, material

Temperature thresholds (>50°C critical)

Catastrophic failure potential

Other Mechanisms:

Erosion-corrosion in high-velocity areas

Cavitation in pumps and valves

Corrosion fatigue under cyclic loading

Galvanic corrosion between dissimilar metals

Day 2: Materials Selection

Morning Session: Weak Acid Section Materials

Materials for Absorption Systems

Mastering material selection:

Stainless Steel Grades:

AISI 304/304L: limited applications

AISI 316/316L: improved resistance

Duplex stainless steels: 2205, 2507

Super austenitic: 904L, AL-6XN, 254SMO

Alloy 20: excellent for weak acid

Selection Criteria:

Acid concentration and temperature

Chloride content: most critical (<25 ppm)

Velocity and turbulence

Equipment criticality

Cost-effectiveness

Equipment-Specific Materials:

Absorption towers: 304L or higher grades

Coolers and condensers: 316L minimum, titanium preferred

Pumps: 316L, duplex, super austenitic

Piping: 304L/316L for dilute acid

Storage tanks: stainless or lined carbon steel

Titanium Applications:

Unalloyed titanium: Grade 1, Grade 2

Excellent corrosion resistance

Primary use: heat exchangers, condensers

Cost and hydrogen embrittlement considerations

Afternoon Session: Strong Acid and High-Temperature Materials

Advanced Materials

Understanding severe environment materials:

Concentrated Acid Service:

Aluminum and aluminum alloys: excellent for >82% acid

1100, 3003, 5052 aluminum grades

Passive film formation

Temperature limitations (<50°C optimal)

Chloride and heavy metal sensitivity

High-Temperature Section:

Platinum-rhodium alloys: catalyst

Stainless steels: 310S, 330 for ductwork

Inconel alloys: 600, 601, 625

Heat-resistant cast alloys

Refractory materials

Nickel-Based Alloys:

Hastelloy C-276: excellent resistance

Inconel 625: high temperature performance

Alloy C-22, C-2000: superior performance

Applications: valves, critical equipment

High cost limiting use

Alternative Materials:

Glass-lined equipment

Fluoropolymer linings: PTFE, PFA

Rubber linings: natural and synthetic

Fiber-reinforced plastics (FRP)

Graphite and ceramic materials

Day 3: Common Failure Modes and Case Studies

Morning Session: Typical Failures

Understanding Plant Failures

Identifying common failure modes:

Chloride-Induced Failures:

Chloride SCC: most catastrophic

Sources: cooling water leaks, contamination

Pitting precursor to SCC

Rapid propagation

Prevention through chloride control

Sensitization Failures:

Intergranular attack in HAZ

Knife-line attack adjacent welds

Carbide precipitation during welding

304/304H versus 304L differences

Stabilized grades (321, 347)

Erosion-Corrosion:

High-velocity acid attack

Pump impeller failures

Valve trim erosion

Piping elbow failures

Design velocity limitations

Under-Insulation Corrosion:

External chloride SCC

Water ingress mechanisms

Temperature cycling condensation

Insulation material selection

Inspection challenges

Afternoon Session: Case Studies

Learning from Failures

Analyzing actual incidents:

Case Study 1: Absorber Tower SCC:

Catastrophic rupture incident

Root cause: chloride contamination

Material: 304L stainless steel

Contributing factors: stress, temperature

Corrective actions: upgrade, monitoring

Lessons learned

Case Study 2: Heat Exchanger Failures:

Pitting and crevice corrosion

Material selection inadequacy

Upgrade to titanium tubes

Design improvements

Maintenance changes

Case Study 3: Piping System Failures:

Erosion-corrosion at flow changes

Velocity-induced attack

Design modifications

Material upgrades to duplex

Inspection frequency

Root Cause Analysis:

Investigation procedures

Sample collection

Laboratory analysis: metallography, SEM

Mechanical testing

Chemical analysis

Determining root causes

Day 4: Prevention and Monitoring

Morning Session: Prevention Strategies

Proactive Management

Implementing prevention programs:

Material Selection Excellence:

Proper grade selection

Chloride limits for materials

Temperature and concentration mapping

Safety factors

Life-cycle cost analysis

Design for Prevention:

Avoiding crevices and dead-legs

Proper drainage

Smooth flow transitions

Gasket material selection

Insulation system design

Accessibility for inspection

Process Control:

Chloride monitoring (<25 ppm critical)

Temperature control

Acid concentration management

Velocity control

Contaminant exclusion

Water quality management

Protection Methods:

Protective coatings and linings

Temporary inhibitors during shutdowns

Nitrogen blanketing

Cathodic protection considerations

Afternoon Session: Monitoring and Inspection

Detecting Corrosion Early

Implementing monitoring programs:

Corrosion Monitoring:

Corrosion coupons: weight loss

Electrical resistance (ER) probes

Linear polarization resistance (LPR)

Ultrasonic thickness monitoring

Online analyzers

Data trending

Non-Destructive Testing:

Visual inspection

Ultrasonic thickness testing (UTT)

Radiographic testing (RT)

Magnetic particle testing (MT)

Liquid penetrant testing (PT)

Eddy current for tubes

Inspection Planning:

Risk-based inspection (RBI)

Critical equipment identification

Damage mechanism assessment

Inspection frequency

Shutdown versus online inspection

Water Chemistry Control:

Cooling water chloride monitoring

Conductivity measurement

pH control

Dissolved oxygen monitoring

Microbiological control

Day 5: Advanced Topics and Integrity Management

Morning Session: Welding and Fabrication

Proper Construction Practices

Understanding fabrication requirements:

Welding Procedures:

Qualified WPS for stainless steels

Low heat input

Interpass temperature control

Filler metal selection (low carbon)

Shielding gas purity

Back purging requirements

Heat Treatment:

Solution annealing: 1040-1120°C

Rapid cooling

Preventing sensitization

Stress relief considerations

Verification testing

Welding Aluminum:

Oxide removal

Inert gas shielding

AC welding requirements

HAZ characteristics

Post-weld inspection

Quality Control:

Visual inspection criteria

NDT requirements

Corrosion testing: ferric sulfate

Hardness testing

Surface finish requirements

Afternoon Session: Integrity Management

Comprehensive Asset Management

Developing management systems:

Regulatory Compliance:

OSHA PSM 1910.119

EPA RMP compliance

Mechanical integrity programs

Process hazard analysis

Management of change

Industry Standards:

ASME codes

API 570: Piping Inspection

NACE corrosion standards

ASTM material specifications

Integrity Management Elements:

Equipment inventory and criticality

Damage mechanism identification

Inspection and testing plans

Fitness-for-service assessments

Remaining life calculations

Repair strategies

Performance Metrics:

Corrosion-related failure rates

Inspection compliance

Mean time between failures

Maintenance costs

Safety indicators

Continuous improvement

Future Trends:

Advanced monitoring technologies

Digital twins and predictive analytics

Machine learning

Nanotechnology coatings

New corrosion-resistant alloys

Course Deliverables

Participants Receive:

Comprehensive corrosion manual

Materials selection charts

Inspection procedure templates

Failure analysis case studies

Regulatory compliance checklists

Professional certificate

Online resources access

Interactive Components:

Metallographic examination

Failed component analysis

Material selection exercises

NDT demonstrations

Group workshops

Why This Training Is Essential

Key Benefits:

Prevent catastrophic failures

Optimize material selection

Extend equipment life

Enhance plant safety

Ensure regulatory compliance

ROI:

Reduced unplanned shutdowns

Lower maintenance costs

Improved plant availability

Decreased safety incidents

Keywords: nitric acid corrosion, materials of construction, stainless steel selection, chloride stress corrosion cracking, intergranular corrosion, titanium heat exchangers, aluminum nitric acid, corrosion failure analysis, NDT inspection, integrity management