Corrosion Aspects and Materials of Construction in Ammonium Nitrate and UAN Plants

$5500.00

Corrosion Aspects and Materials of Construction in Ammonium Nitrate and UAN Plants: 5-Day Specialized Training Course

Course Overview

This intensive 5-day ammonium nitrate and UAN corrosion training provides specialized knowledge of corrosion mechanisms, materials selection, and integrity management for ammonium nitrate (AN) and urea-ammonium nitrate (UAN) solution manufacturing facilities. Designed for materials engineers, corrosion specialists, plant engineers, and safety professionals in fertilizer production.

Target Audience: Materials engineers, corrosion specialists, integrity engineers, plant engineers, maintenance managers, safety professionals, and technical personnel in AN and UAN production facilities.

Course Objectives:

Understand corrosion mechanisms in AN and UAN environments

Master materials selection for different process conditions

Identify failure modes and prevention strategies

Implement inspection and monitoring programs

Ensure process safety and regulatory compliance

Day 1: AN and UAN Processes and Corrosion Fundamentals

Morning Session: Process Overview

Understanding Production Processes

Foundation of AN and UAN manufacturing:

Ammonium Nitrate Production:

Ammonia and nitric acid neutralization reaction

NH₃ + HNO₃ → NH₄NO₃ + heat (exothermic)

Neutralizer reactor: 170-185°C, slightly acidic pH

Evaporation and concentration: 95-99.5% AN solution

Prilling or granulation processes

Product forms: prills, granules, solutions

Plant capacities: 1,000-3,000 MTPD

UAN Solution Production:

Urea and ammonium nitrate mixture in water

Common grades: UAN-28, UAN-30, UAN-32 (% nitrogen)

Typical composition: 35-45% AN, 35-45% urea, water

Production temperature: 60-80°C

Salt-out temperature considerations

Storage and handling requirements

Corrosive Environment Characteristics:

Ammonium nitrate: oxidizing, acidic to neutral

Nitric acid carryover effects

Ammonia excess buffering

Temperature impacts on corrosivity

Chloride contamination sensitivity

Dissolved oxygen influence

Afternoon Session: Corrosion Mechanisms

How Corrosion Occurs

Understanding corrosion fundamentals:

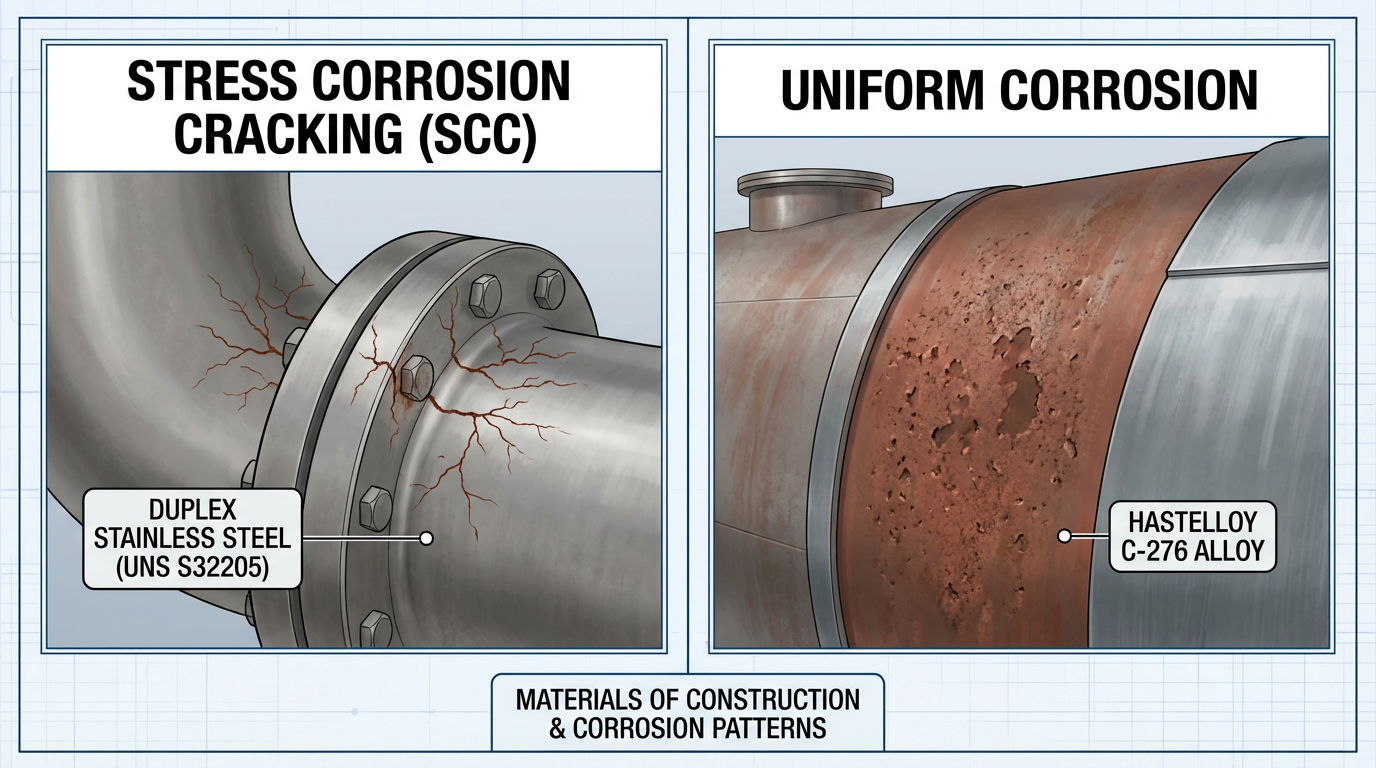

General Corrosion:

Uniform attack on carbon steel

Passivity breakdown in stainless steels

pH effects: acidic solutions most aggressive

Temperature acceleration of corrosion

Concentration effects on corrosion rates

Oxygen availability impact

Stress Corrosion Cracking (SCC):

Chloride SCC in stainless steels: critical concern

Nitrate SCC in carbon steel (rare but possible)

Required conditions: stress, environment, susceptible material

Temperature thresholds (>60°C increases risk)

Catastrophic failure potential

Historical incidents and consequences

Localized Corrosion:

Pitting corrosion: chloride and nitrate synergy

Crevice corrosion in flanges and gaskets

Under-deposit corrosion

Galvanic corrosion at dissimilar metal junctions

Preferential weld attack

Intergranular Corrosion:

Sensitization of stainless steels

Grain boundary attack in HAZ

Carbide precipitation effects

Stabilized grade performance

Prevention strategies

Erosion-Corrosion:

High-velocity solution attack

Two-phase flow damage

Pump and valve failures

Cavitation in pumps

Velocity limitations by material

Day 2: Materials Selection for AN Plants

Morning Session: Neutralization and Evaporation Section

Materials for High-Temperature AN

Mastering material selection:

Neutralizer Materials:

Stainless steel 304L/316L: baseline materials

Alloy 20 (Carpenter 20Cb-3): excellent performance

Alloy 31 (UNS N08031): high corrosion resistance

Duplex stainless steels: 2205 for severe service

Titanium: exceptional resistance, high cost

Temperature and pH considerations

Evaporator Materials:

316L stainless steel: moderate conditions

Super austenitic grades: 904L, AL-6XN

Alloy 20: preferred for acidic conditions

Titanium tubes: superior performance

Shell materials: carbon steel or 304L

Chloride content critical (<50 ppm)

Selection Criteria:

Solution pH (acidic to neutral range)

Operating temperature: 150-200°C

Chloride contamination levels

Nitric acid concentration

Ammonia excess buffering

Equipment criticality and cost

Afternoon Session: Finishing and Storage

Materials for Downstream Operations

Understanding lower temperature materials:

Concentration and Finishing:

Prilling tower: carbon steel with coatings

Granulation drum: stainless steel 304L/316L

Product conveyors: carbon steel or stainless

Dust collection: 304L or FRP

Screening equipment: carbon steel adequate

Coating and anti-caking systems

Storage Systems:

AN solution storage: 316L or Alloy 20

Temperature control critical: prevent crystallization

Heating coils: titanium or Alloy 20

Tank design: ASME codes compliance

Insulation and heat tracing

Vent and pressure relief systems

Alternative Materials:

Glass-lined equipment for acidic service

Fluoropolymer linings: PTFE, PFA

Rubber linings: butyl, natural rubber

Fiber-reinforced plastics (FRP)

Protective coatings for carbon steel

Epoxy and polyurethane systems

Day 3: Materials Selection for UAN Plants

Morning Session: UAN Production Materials

Materials for UAN Solutions

Mastering UAN-specific selection:

Reactor and Mixing Section:

Stainless steel 316L: most common

Alloy 20: excellent corrosion resistance

Duplex 2205: improved resistance

Carbon steel: limited to low-temperature, low-chloride

Agitator materials: 316L or duplex

Heating systems: stainless steel coils

Temperature-Dependent Selection:

<60°C: 316L adequate with chloride control

60-80°C: 316L or duplex recommended

80°C: super austenitic or Alloy 20

Chloride limits stricter at higher temperatures

Salt-out temperature considerations

Seasonal variation impacts

UAN Solution Characteristics:

Mildly corrosive compared to pure AN

Urea buffering effect

pH typically 7-8 (near neutral)

Chloride sensitivity remains critical

Temperature cycling effects

Contamination from raw materials

Afternoon Session: Storage and Handling

UAN Distribution Systems

Understanding storage and transfer materials:

Storage Tanks:

Carbon steel: adequate for low-chloride UAN

Stainless steel 304L/316L: preferred

Polyethylene and FRP: non-metallic options

Tank capacity: 1,000-50,000 tonnes

Temperature maintenance systems

Agitation to prevent settling

Transfer and Loading:

Piping: carbon steel or 304L stainless

Pumps: 316L stainless steel standard

Loading arms: stainless steel

Hoses: reinforced rubber or composite

Valves: stainless steel or bronze

Gasket materials: PTFE or graphite

Applicator Equipment:

Field application equipment: carbon steel

Spray nozzles: stainless steel or plastic

Seasonal corrosion: outdoor exposure

Cleaning and flushing requirements

Atmospheric corrosion protection

Maintenance and inspection

Day 4: Corrosion Prevention and Monitoring

Morning Session: Prevention Strategies

Proactive Corrosion Management

Implementing prevention programs:

Process Control:

pH control: slightly acidic to neutral optimal

Ammonia excess maintenance

Chloride monitoring and control (<50 ppm)

Temperature management within design

Dissolved oxygen minimization

Raw material quality specifications

Design Considerations:

Avoiding crevices and dead-legs

Proper drainage and low-point drains

Smooth flow transitions

Stress concentration minimization

Material compatibility at joints

Thermal expansion accommodation

Inhibition Programs:

Passivating agents for stainless steel

Ammonia as pH buffer

Oxygen scavenging chemicals

Temporary inhibitors during shutdowns

Nitrogen blanketing in storage

Water quality control

Operational Best Practices:

Controlled startup and shutdown

Temperature ramping procedures

Avoiding thermal shock

Regular system flushing

Equipment idle time management

Preventive maintenance scheduling

Afternoon Session: Monitoring and Inspection

Detecting Corrosion Early

Implementing monitoring programs:

Corrosion Monitoring:

Corrosion coupons: weight loss measurement

Electrical resistance (ER) probes

Ultrasonic thickness monitoring

Process analyzers: pH, chloride, conductivity

Temperature profiling

Data trending and analysis

Non-Destructive Testing:

Visual inspection procedures

Ultrasonic thickness testing (UTT)

Radiographic testing for welds

Magnetic particle testing

Liquid penetrant testing

Infrared thermography for CUI

Inspection Planning:

Risk-based inspection (RBI) methodology

Critical equipment identification

Damage mechanism assessment

Inspection intervals optimization

Seasonal inspection considerations

Shutdown planning and coordination

Sample Analysis:

Chloride content analysis

pH measurement and trending

Heavy metal contamination

Nitrate and ammonia concentration

Corrosion product analysis

Metallographic examination

Day 5: Safety, Incidents, and Integrity Management

Morning Session: Process Safety and Incidents

Safety in AN and UAN Plants

Understanding safety considerations:

AN Detonation Hazards:

Thermal decomposition pathways

Contaminant sensitivity: organics, chlorides, metals

Historical catastrophic incidents

Beirut (2020), West, Texas (2013)

Prevention through contamination control

Storage and handling regulations

Material-Safety Interaction:

Corrosion leading to contamination

Iron oxide catalyzing decomposition

Chloride impact on stability

Organic material ingress prevention

Proper material selection importance

Cleaning and decontamination procedures

Case Studies:

Material failure leading to safety incidents

Chloride-induced SCC failures

Contamination from corrosion products

Tank rupture incidents

Piping failures and releases

Lessons learned and corrective actions

Emergency Preparedness:

Leak detection and monitoring

Emergency response procedures

Material compatibility in emergencies

Neutralization and cleanup

Environmental protection

Incident investigation protocols

Afternoon Session: Integrity Management

Comprehensive Asset Management

Developing management systems:

Regulatory Compliance:

OSHA PSM 1910.119: AN facilities

EPA RMP requirements for AN

ATF explosives regulations

UN classification and storage

Mechanical integrity programs

Process hazard analysis

Industry Standards:

EFMA (European Fertilizer Manufacturers): guidelines

IFA (International Fertilizer Association): best practices

ASME codes for pressure vessels

API inspection codes

NACE corrosion standards

ISO safety management

Integrity Management Elements:

Asset inventory and criticality ranking

Corrosion damage mechanisms identification

Inspection and testing procedures

Fitness-for-service assessments

Remaining life calculations

Repair versus replacement decisions

Documentation and Records:

Material traceability

Inspection history and reports

Corrosion monitoring data

Maintenance records

Incident investigations

Management of change documentation

Continuous Improvement:

Performance metrics and KPIs

Benchmarking against industry

Technology upgrades evaluation

Training and competency programs

Lessons learned integration

Innovation in materials and methods

Course Deliverables

Participants Receive:

Comprehensive corrosion and materials manual

Materials selection decision trees

Inspection procedure templates

Process safety checklists

Case study compilation

Regulatory compliance guides

Professional certificate of completion

Interactive Components:

Materials sample examination

Failure analysis workshops

Material selection exercises

Safety scenario discussions

Group case study analysis

Why This Training Is Critical

Key Benefits:

Prevent equipment failures and production losses

Ensure process safety and prevent incidents

Optimize material selection and costs

Extend equipment service life

Maintain regulatory compliance

Build organizational expertise

ROI:

Reduced unplanned shutdowns

Lower maintenance and replacement costs

Improved safety performance

Enhanced regulatory standing

Avoided catastrophic incidents

Keywords: ammonium nitrate corrosion, UAN materials, fertilizer plant corrosion, stainless steel selection, chloride stress corrosion cracking, AN plant safety, materials of construction, corrosion monitoring, integrity management, process safety management

Word Count: ~1,000 words

This SEO-optimized course outline provides comprehensive coverage of corrosion and materials topics for ammonium nitrate and UAN plants, addressing mechanisms, prevention, safety, and management for reliable and safe operations.