Corrosion and Materials Technology in Urea Plants

$5500.00

Corrosion and Materials Technology in Urea Plants: 5-Day Specialized Training Course

Course Overview

This intensive 5-day corrosion and materials technology training provides specialized knowledge for managing corrosion challenges in urea manufacturing facilities. Designed for materials engineers, corrosion specialists, maintenance professionals, and plant engineers responsible for equipment reliability.

Target Audience: Materials engineers, corrosion specialists, integrity engineers, maintenance managers, metallurgists, inspection specialists, and technical professionals in urea facilities.

Course Objectives:

Understand corrosion mechanisms in urea environments

Master material selection for urea equipment

Implement corrosion prevention strategies

Apply inspection and monitoring techniques

Develop integrity management programs

Day 1: Corrosion Fundamentals in Urea Environment

Morning Session: Urea Process and Corrosive Environments

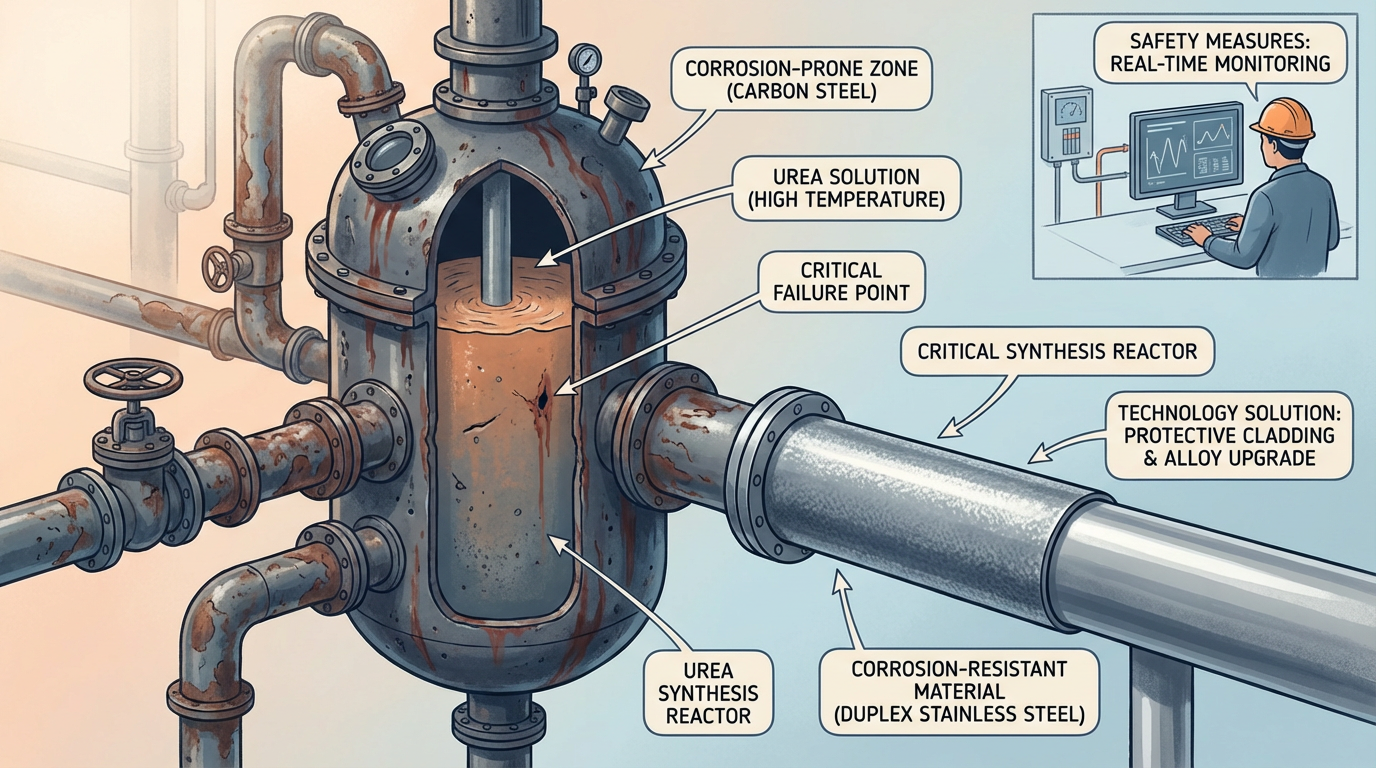

Understanding Corrosion Challenges

Foundation of corrosion in urea plants:

Urea Process Overview:

High-pressure synthesis (140-160 bar, 180-200°C)

Medium and low-pressure recovery sections

Vacuum concentration systems

Finishing: prilling and granulation

Process fluids: ammonia, CO₂, urea, carbamate solutions

Corrosive Environment Characteristics:

Ammonium carbamate corrosivity: highly aggressive

Temperature and pressure effects

pH variations throughout process

Oxygen content critical role

Impurities: chlorides, sulfates, cyanides

Velocity effects and erosion-corrosion

Afternoon Session: Corrosion Mechanisms

Types of Corrosion

Understanding corrosion mechanisms:

General and Localized Corrosion:

Uniform attack and corrosion rates

Pitting corrosion: initiation and propagation

Crevice corrosion in flanges

Galvanic corrosion between dissimilar metals

Deposit-induced corrosion

Stress Corrosion Cracking (SCC):

Chloride SCC in stainless steels: most critical concern

Carbonate SCC mechanisms

Susceptible materials and conditions

Crack morphology and detection

Threshold stress and temperature sensitivity

Other Mechanisms:

Intergranular corrosion and sensitization

Grain boundary chromium depletion

Erosion-corrosion in high-velocity areas

Corrosion fatigue in cyclic loading

Hydrogen embrittlement considerations

Day 2: Materials Selection and Specifications

Morning Session: High-Pressure Section Materials

Synthesis Section Materials

Mastering material selection for critical equipment:

Stainless Steel Grades:

AISI 316L (1.4404): baseline material

AISI 316Ti and 321 (stabilized grades)

Duplex stainless steels: 2205, 2507

Super austenitic: 904L, AL-6XN

Specialty alloys: 25-22-2 (Sanicro 28)

Safurex (high nitrogen austenitic)

Equipment-Specific Materials:

Urea reactor: 25-22-2, Safurex, 316L Ti-stabilized

HP carbamate condenser: titanium, zirconium

HP stripper: 25-22-2, duplex grades

HP scrubber: 316L, 25-22-2

Pumps and valves: duplex or super austenitic

Titanium and Zirconium:

Unalloyed titanium: Grade 1, Grade 2

Excellent corrosion resistance, lightweight

Carbamate condenser tubes: primary application

Zirconium 702/705 for extreme conditions

Cost considerations and selective use

Afternoon Session: Recovery and Finishing Materials

Downstream Materials

Understanding materials for less severe environments:

Recovery Section:

MP decomposer: 316L, duplex stainless steels

LP decomposer: 316L adequate

Hydrolysis reactor: carbon steel with cladding

Heat exchangers: 316L tubes

Process condensate handling: 316L or duplex

Concentration and Finishing:

Evaporators: 316L minimum

Vacuum system: 316L

Prilling tower: carbon steel with coatings

Granulators: carbon steel, stainless internals

Product handling: carbon steel

Alternative Materials:

Nickel-based alloys: Inconel, Hastelloy

Composite materials and linings

Polymer linings and coatings

Material testing and qualification protocols

Day 3: Corrosion Prevention and Mitigation

Morning Session: Passivation and Inhibition

Active Prevention Strategies

Implementing corrosion prevention:

Passivation Procedures:

Air passivation process: most common method

Oxygen injection rates (0.5-3% by volume)

Ammonia presence requirements

Temperature and pressure conditions

Pre-commissioning and periodic re-passivation

Passivation effectiveness monitoring

Corrosion Inhibition:

Oxygen as corrosion inhibitor: mechanism

Ammonia excess for pH control

Proprietary chemical inhibitors

Neutralizing amines in condensate

Inhibitor injection and dosing

Process Control:

Maintaining optimal NH₃:CO₂ ratio

Temperature and pressure stability

Minimizing air ingress

Chloride control (<2 ppm critical)

Water quality management

Afternoon Session: Design and Operational Practices

Corrosion-Resistant Design

Applying design principles:

Design Considerations:

Proper material selection per ISO 15613

Avoiding dissimilar metal contact

Crevice elimination in design

Proper drainage and dead-leg elimination

Stress concentration minimization

Weld design and inspection access

Welding Practices:

Qualified welding procedures (WPS/PQR)

Low heat input techniques

Post-weld heat treatment (PWHT) requirements

HAZ sensitization prevention

Weld overlay and cladding techniques

Operational Best Practices:

Controlled startup and shutdown procedures

Equipment idle time management

Cleaning and decontamination protocols

Layup procedures for maintenance

Nitrogen blanketing during outages

Water washing procedures and requirements

Day 4: Inspection and Monitoring Techniques

Morning Session: Non-Destructive Examination

NDT Methods

Mastering inspection techniques:

Ultrasonic Testing (UT):

Thickness measurement programs

Corrosion mapping and data management

Advanced UT: PAUT, TOFD

Remaining life assessment

Visual Inspection:

External and internal techniques

Borescope and videoscope applications

Corrosion morphology identification

Documentation and photography

Other NDT Methods:

Magnetic particle testing (MT): surface cracks

Liquid penetrant testing (PT)

Radiographic testing (RT): weld defects

Eddy current: tube inspection

Acoustic emission: real-time monitoring

Destructive Testing:

Metallographic examination

Boat sample analysis

Corrosion coupon programs

Intergranular corrosion testing: ASTM A262

Afternoon Session: Corrosion Monitoring

Real-Time Monitoring

Implementing continuous monitoring:

Monitoring Techniques:

Electrical resistance (ER) probes

Linear polarization resistance (LPR)

Corrosion potential monitoring

Hydrogen probes for SCC risk

Online thickness monitoring

Ultrasonic monitoring badges

Process Monitoring:

Oxygen content analyzers

pH and conductivity measurements

Chloride and contaminant analyzers

Data integration and analysis

Inspection Planning:

Risk-based inspection (RBI) methodology

API 580/581 application

Damage mechanism identification

Inspection frequency optimization

Critical equipment prioritization

Documentation and database management

Day 5: Failure Analysis and Advanced Topics

Morning Session: Failure Investigation

Root Cause Analysis

Expertise in failure investigation:

Failure Analysis Process:

Incident documentation and evidence collection

Visual examination and photography

Laboratory analysis: metallography, SEM

Mechanical testing of failed components

Root cause determination

Corrective action development

Common Failure Modes:

SCC in HP equipment: case studies

Pitting failures in stainless steel

Erosion-corrosion in high-velocity areas

Weld-related failures: HAZ attack

Carbamate condenser tube failures

Pump and valve corrosion failures

Real-World Case Studies:

Reactor corrosion incidents

Stripper and condenser failures

Catastrophic versus gradual failures

Lessons learned and improvements

Cost impact analysis

Afternoon Session: Advanced Topics and Future Trends

Emerging Technologies

Exploring innovations:

Advanced Materials:

Next-generation stainless steels

Nano-structured materials

Cost-effective alternatives

Performance in aggressive environments

Coating Technologies:

High-performance polymer coatings

Glass-lined equipment

Thermal spray coatings

Coating inspection and quality control

Corrosion Modeling:

CFD for flow-induced corrosion

Corrosion prediction models

Machine learning for failure prediction

Digital twin applications

Industry Standards:

ISO 15613: Urea plant materials

NACE standards for corrosion control

API and ASME codes

Emerging regulations

Sustainability and Green Urea:

Materials for green ammonia feedstock

Hydrogen compatibility

Carbon capture integration impacts

Extended equipment life strategies

Material recycling and circular economy

Integrity Management:

Asset integrity management systems

Corrosion management strategy

Key performance indicators (KPIs)

Benchmarking and continuous improvement

Course Deliverables

Participants Receive:

Comprehensive corrosion and materials manual

Material selection guidelines

Inspection procedure templates

Corrosion monitoring framework

Case study compilation

Standards reference guide

Professional certificate of completion

Online technical resources access

Interactive Learning:

Metallographic sample examination

NDT equipment demonstrations

Failure analysis workshops

Material selection exercises

Group case discussions

Why This Training Is Essential

Key Benefits:

Prevent catastrophic equipment failures

Optimize material selection and costs

Extend equipment life significantly

Reduce unplanned shutdowns

Enhance safety and environmental performance

Build organizational expertise

ROI:

Reduced equipment replacement costs

Minimized production losses

Optimized inspection spending

Extended turnaround intervals

Improved plant reliability