Combined Heat and Power (CHP) modeling

$5500.00

Combined Heat & Power (CHP) Modeling: Advanced 5-Day Training Course

Course Overview

This specialized Combined Heat and Power (CHP) Modeling training program delivers comprehensive expertise for energy professionals across the Kingdom of Saudi Arabia (KSA), Oman, GCC countries (UAE, Qatar, Kuwait, Bahrain), and Africa. The course covers cogeneration fundamentals, thermodynamic cycles, CHP technologies, performance modeling, economic analysis, and optimization strategies essential for designing efficient, sustainable power and thermal energy systems in industrial, commercial, and utility sectors.

With the Middle East and Africa investing over $100 billion in power infrastructure, this training addresses critical competencies for professionals at Saudi Aramco, SABIC, SEC, PDO, ADNOC, DEWA, achieving 70-90% fuel efficiency supporting Saudi Vision 2030, UAE Energy Strategy 2050, and regional decarbonization goals.

Target Audience

Power Engineers designing CHP systems in Saudi Arabia, Oman, GCC, Africa

Energy Managers optimizing industrial energy systems

Process Engineers integrating CHP with facilities

Utility Engineers in refineries, petrochemical plants

Project Engineers evaluating cogeneration investments

Sustainability Managers reducing carbon footprint

Operations Personnel managing combined cycle plants

Day 1: CHP Fundamentals & Thermodynamic Principles

Morning Session: Introduction to Cogeneration

CHP definition: simultaneous electricity and thermal energy production

Benefits: 70-90% fuel efficiency, emissions reduction, cost savings, reliability

Applications: refineries (Saudi Aramco), petrochemicals (SABIC), desalination (SWCC)

Power-to-heat ratios for different technologies

Regulatory framework: Saudi Arabia, Oman, GCC utility policies, grid connection

Case studies: SATORP cogeneration, Shuqaiq IWPP, African industrial CHP

Afternoon Session: Thermodynamic Cycles

First and second laws: energy conservation, entropy, exergy concepts

Rankine cycle: steam cycle fundamentals, reheat, regenerative configurations

Brayton cycle: gas turbine components, compressor, combustor, turbine

Combined cycle: gas turbine + steam cycle integration, HRSG configurations

Performance parameters: thermal, electrical, overall efficiency, fuel utilization factor

Exergy analysis: identifying irreversibilities, second-law efficiency

Workshop: Thermodynamic cycle calculations for CHP

Day 2: CHP Technologies & Equipment

Morning Session: Gas Turbine & Steam Turbine CHP

Gas turbine cogeneration: simple cycle with heat recovery, most common in GCC

Gas turbine types: Frame, aeroderivative for different applications

HRSG design: unfired, supplementary fired, multi-pressure configurations

Combined cycle efficiency: up to 60% electrical + thermal output

Major suppliers: GE, Siemens, Mitsubishi widely deployed in Middle East

Steam turbine types: backpressure, extraction, condensing turbines

Fuel flexibility: natural gas (GCC primary), diesel, syngas for Africa

Emissions control: DLN combustors, SCR for environmental compliance

Afternoon Session: Reciprocating Engines & Alternatives

Reciprocating engine CHP: 35-45% electrical efficiency, 100 kW - 10 MW range

Heat recovery: jacket water, exhaust gas, lube oil cooling

Microturbines: 30-300 kW, compact, low maintenance

Fuel cells: SOFC, MCFC for high-efficiency applications

Waste heat to power: ORC, Kalina cycle for low-temperature recovery

Trigeneration (CCHP): cooling, heating, power with absorption chillers

Solar-CHP hybrids: CSP integration, PV + gas turbine

Case studies: Engine CHP in Nigeria, UAE microturbines, Saudi IWPP

Day 3: CHP System Modeling & Simulation

Morning Session: Modeling Fundamentals

Modeling objectives: performance prediction, optimization, economic evaluation

Component modeling: energy and mass balances

Off-design performance: part-load, ambient temperature effects (45-50°C in GCC)

Simulation software: Aspen HYSYS, EBSILON, Thermoflex, GT PRO

Building models: gas turbine, HRSG, steam turbine configuration

Input parameters: fuel specs, ambient conditions, efficiencies

Output analysis: power, thermal output, fuel consumption, emissions

Workshop: Building basic CHP model

Afternoon Session: Advanced Modeling

Combined cycle modeling: integrated gas turbine-HRSG-steam turbine

Multi-pressure HRSG optimization

Part-load curves: characteristic performance throughout load range

Heat integration: pinch analysis, process integration

Steam network modeling with headers and letdown stations

Dynamic modeling: transient behavior, startup/shutdown

Optimization modeling: efficiency maximization, cost minimization

Workshop: Advanced combined cycle modeling with optimization

Day 4: Economic Analysis & Feasibility Studies

Morning Session: CHP Economics

Capital costs: equipment, installation, balance of plant

Gas turbine costs: $/kW for different sizes (5-300 MW)

Regional cost factors: Saudi Arabia, UAE, Oman, Africa construction

Operating costs: fuel, O&M, labor, consumables

Fuel costs: GCC natural gas pricing, African diesel costs

O&M schedules: combustion inspections (8,000-12,000 hrs), major overhauls (24,000-48,000 hrs)

Revenue streams: electricity savings/sales, thermal energy value

Electricity tariffs: Saudi Arabia (18-32 SAR/MWh), GCC, Africa

Spark spread analysis: electricity price minus fuel cost

Afternoon Session: Financial Analysis

Financial metrics: NPV, IRR, payback period

Discount rates: GCC (6-10%), Africa (12-18%)

LCOE: levelized cost of electricity and thermal energy

Cash flow analysis: revenues, costs, depreciation, taxes

Sensitivity analysis: fuel price, electricity price, capacity factor impacts

Risk assessment: fuel supply, regulatory, technology, market risks

Feasibility framework: technical, economic, environmental assessment

Case studies: Saudi Aramco CHP economics, Oman industrial feasibility

Workshop: Complete economic analysis using spreadsheet models

Day 5: Performance Optimization & Future Technologies

Morning Session: CHP Optimization

Operational optimization: load dispatch, part-load operation

Thermal storage: hot water, steam accumulators for load shifting

Efficiency improvements: inlet air cooling, steam injection (critical for GCC heat)

15-20% power loss at 50°C ambient temperature mitigation

Advanced control: load following, grid synchronization, frequency regulation

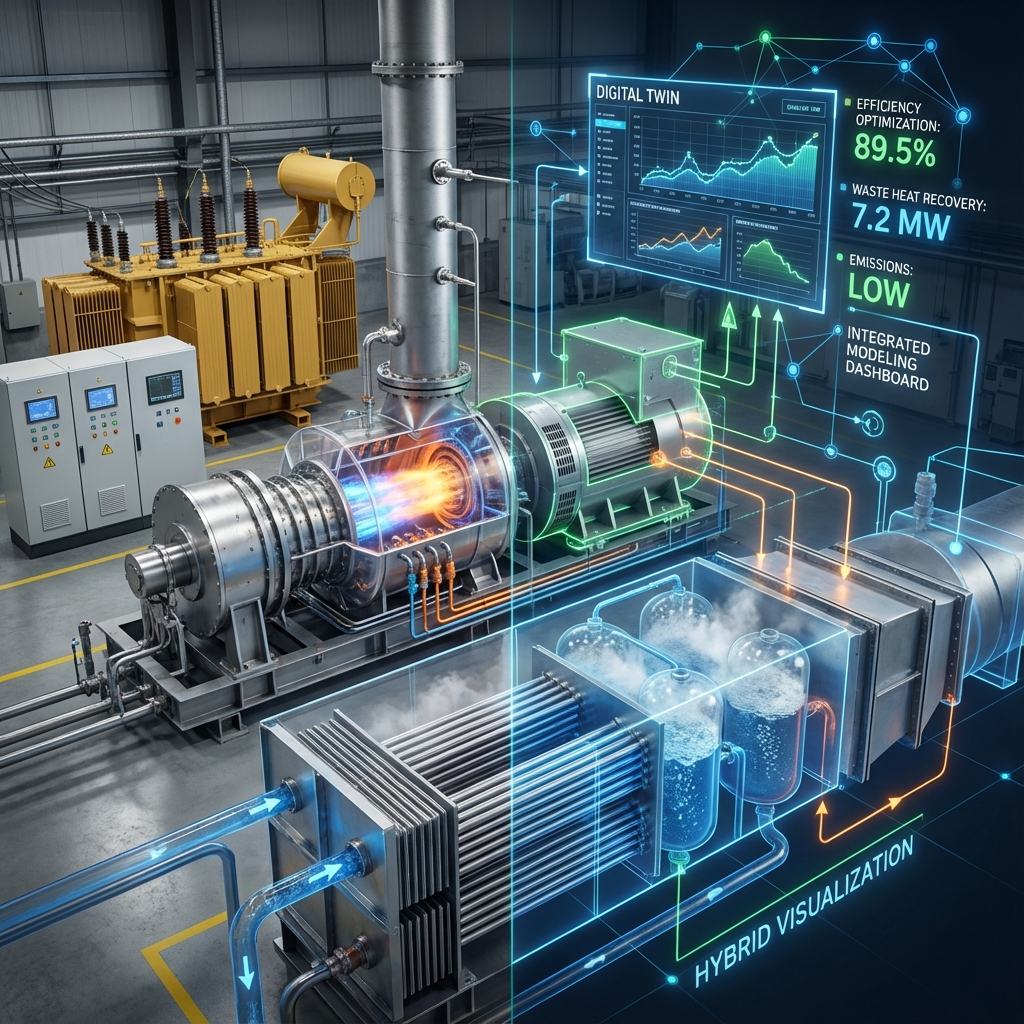

Digitalization: SCADA, optimization software, machine learning, digital twins

Fuel optimization: switching capability, hydrogen blending readiness

Retrofit opportunities: repowering, adding HRSG, turbine upgrades

Case studies: Saudi power plant improvements, ADNOC optimizations

Afternoon Session: Emerging Technologies

Hydrogen-ready turbines: blending up to 100% hydrogen capability

Saudi hydrogen economy: green/blue hydrogen integration

CCUS integration: carbon capture from CHP exhaust

NEOM hydrogen hub, UAE carbon capture initiatives

Hybrid renewable-CHP: solar + CHP, wind + CHP with battery storage

Waste-to-energy CHP: municipal waste, biomass for Africa

Distributed energy: microgrids, virtual power plants, grid services

Decarbonization pathways: CHP role in energy transition

Regional alignment: Saudi Green Initiative (278 Mt CO2 reduction), UAE Net Zero 2050

Final project: Comprehensive CHP design, modeling, feasibility study presentation

Learning Outcomes

Upon completion, participants will be able to:

Understand thermodynamic principles underlying CHP cycles

Select appropriate CHP technology based on application requirements

Model CHP systems using industry-standard simulation software

Conduct economic feasibility studies with financial analysis

Optimize CHP performance for efficiency and cost objectives

Evaluate integration with industrial processes and district energy

Assess emerging technologies: hydrogen, CCUS, renewable hybrids

Develop business cases supporting CHP investment decisions

Course Delivery & Certification

Format: Technical lectures, thermodynamic workshops, software demos, economic modeling, case studies

Software: Hands-on with CHP simulation tools (Thermoflex/EBSILON/Aspen HYSYS demos)

Materials: Manual, thermodynamic tables, cost databases, economic templates, case studies

Certification: Professional certificate recognized across KSA, Oman, UAE, Qatar, Kuwait, Bahrain, Africa

Language: English (Arabic support available)

CPD Credits: Continuing professional development for engineers

Locations: Riyadh, Dhahran, Jubail (KSA), Muscat (Oman), Dubai, Abu Dhabi, Doha, Lagos, Cairo, Johannesburg

Why This Course is Strategic

The GCC industrial sector consumes massive electricity and steam simultaneously—ideal for CHP. Saudi Aramco operates over 10 GW cogeneration capacity. IWPP projects combine power, water, industrial steam. African development requires efficient distributed generation. CHP achieves 30-40% fuel savings versus separate generation—critical for economic competitiveness and meeting carbon reduction commitments.

This training delivers practical expertise incorporating international standards, GE/Siemens turbine technologies, Saudi Aramco practices, addressing extreme ambient temperatures, fuel availability, water-energy nexus, supporting Saudi Vision 2030 energy efficiency targets (13% by 2030) and regional sustainability transformation.

Master cogeneration. Optimize energy. Power the future sustainably.