ASNT Level II - Radiographic Testing (RT)

$2000.00

ASNT Level II - Radiographic Testing (RT)

Course Overview

Program Title: ASNT Level II Radiographic Testing (RT) Certification Training

Duration: 10 Days (80 Hours) + Exam

Schedule: December 1-12, 2025 | February 9-20, 2026

Timing: Full-Day (8:00 AM - 5:00 PM)

Location: Riyadh, Jubail Industrial City

Course Code: STC-RT2-2025-12

Investment: 7,500 SAR (includes training, exam, certification preparation)

Course Description:

Comprehensive ASNT SNT-TC-1A Level II Radiographic Testing (RT) certification training program. Prepares NDT technicians for Level II RT certification in accordance with ASNT Recommended Practice SNT-TC-1A and international standards (ISO 9712, EN 473).

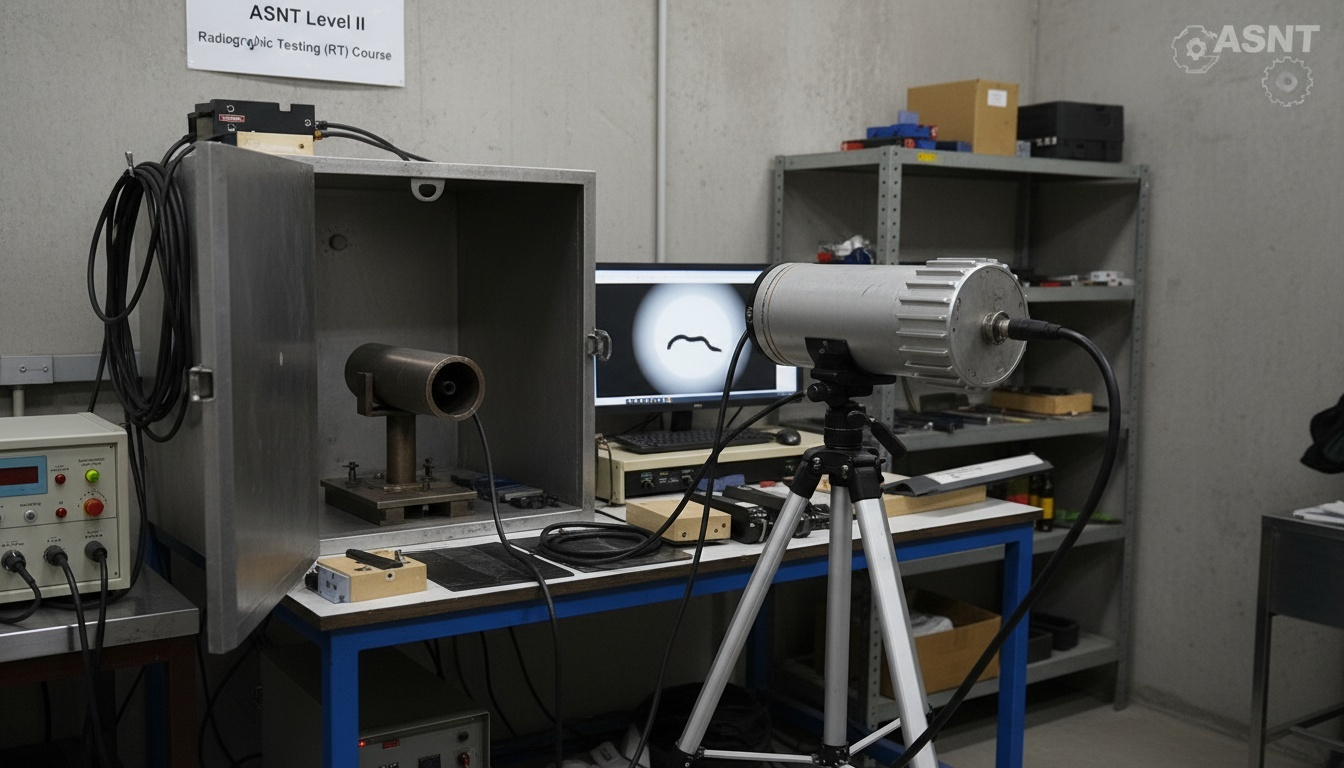

Course covers X-ray and gamma-ray radiography principles, equipment operation, film processing, radiographic interpretation, discontinuity evaluation, code requirements (ASME, AWS, API), safety regulations, and hands-on radiographic testing of welds and castings.

Target Audience:

NDT technicians seeking RT Level II certification

RT Level I technicians upgrading to Level II

QA/QC inspectors in fabrication and construction

Welding inspectors (CWI/CSWIP) adding RT qualification

Aramco, SABIC, ADNOC, EPC contractor NDT personnel

Prerequisites:

ASNT Level I RT certification (or equivalent experience)

Minimum training and experience per SNT-TC-1A:

Level II requires: 40 hours training + 2,000 hours (1 year) experience in RT

Employer certification required after course completion

Medical fitness (radiation exposure limits, vision requirements)

Course Curriculum

Days 1-2: RT Principles & X-Ray Equipment

Electromagnetic radiation and X-ray production

X-ray tube construction and operation

Gamma-ray sources: Ir-192, Co-60, Se-75

Radiation characteristics: Wavelength, frequency, energy (keV)

Interaction with matter: Photoelectric effect, Compton scattering

Radiation intensity and inverse square law

Beam quality and half-value layer (HVL)

X-ray and gamma-ray equipment: Industrial X-ray generators, isotope cameras

Equipment inspection and maintenance

Days 3-4: Film Radiography & Image Quality

Radiographic film: Types, speed, contrast, grain size

Film processing: Manual and automatic processing

Developer, fixer, washing, drying

Darkroom procedures and safelight requirements

Film density and optical density measurement (densitometer)

Contrast: Subject contrast, film contrast

Definition and sharpness: Geometric unsharpness (Ug), film unsharpness

Image Quality Indicators (IQI):

Wire-type IQIs (DIN wires)

Hole-type IQIs (plaque penetrameters per ASTM E142)

Sensitivity requirements per codes

Exposure calculations and technique charts

Hands-On: Expose and process radiographic films, measure density

Days 5-6: Radiographic Techniques & Setups

Single-wall vs. double-wall radiography

Elliptical and tangential techniques

Source-to-film distance (SFD) and geometric considerations

Exposure time calculations

Backscatter radiation and lead screens

Fluorescent screens and intensifying screens

Film identification and location markers

Radiography of various geometries: Pipe welds, plate welds, castings, forgings

Panoramic and tangential exposures

Hands-On: Set up radiographic exposures for pipe welds (2", 6", 12" diameter)

Days 7-8: Discontinuity Identification & Interpretation

Welding discontinuities:

Volumetric: Porosity, slag inclusions, tungsten inclusions

Planar: Cracks (hot cracks, cold cracks), lack of fusion, incomplete penetration

Geometric: Undercut, underfill, excessive reinforcement, concavity

Casting discontinuities: Shrinkage cavities, gas porosity, inclusions, cold shuts

Material discontinuities: Laminations, seams, laps

Radiographic appearance of discontinuities

Acceptance criteria per codes:

ASME Section VIII (UW-51, UW-52)

ASME B31.3 (Table 341.3.2)

AWS D1.1 (Table 6.1)

API 1104 (pipeline welding)

Radiograph evaluation and reporting

Hands-On: Interpret 50+ radiographs, identify and size discontinuities, accept/reject per code

Day 9: Advanced Topics & Code Requirements

Digital radiography (CR - Computed Radiography, DR - Digital Radiography)

Real-time radiography (fluoroscopy)

Neutron radiography

Code requirements:

ASME Section V Article 2 (Radiographic Examination)

ASME Section VIII Division 1 (pressure vessels)

ASME B31.3 (piping)

AWS D1.1 (structural welding)

API 1104 (pipeline welding)

Saudi Aramco SAEP-395 (NDE requirements)

Specification writing and radiographic procedures

Record keeping and archiving radiographs

Day 10: Radiation Safety & Regulations

Biological effects of radiation

Radiation units: Roentgen, rad, rem, Sievert, Becquerel, Curie

Dose limits: Occupational (50 mSv/year), public (1 mSv/year)

ALARA principle (As Low As Reasonably Achievable)

Time, distance, shielding principles

Personal protective equipment and monitoring:

Film badges, TLDs (thermoluminescent dosimeters), pocket dosimeters

Alarming rate meters

Radiation area posting and barriers

Regulations:

Saudi NRRC (National Nuclear and Radiological Regulatory Commission)

IAEA (International Atomic Energy Agency) standards

OSHA and EPA regulations

Emergency response and radiation incidents

Transport of radioactive sources (DOT regulations)

Day 11 (Exam Day): ASNT RT Level II Examination

Exam Structure per SNT-TC-1A:

General Examination (2 hours):

40 multiple-choice questions

Basic principles, physics, equipment, safety

Passing: 70% (28 correct)

Specific Examination (3 hours):

50 multiple-choice questions

Technique, procedures, code requirements specific to RT

Passing: 70% (35 correct)

Practical Examination (4 hours):

Interpret 25-30 radiographs of welds and castings

Identify discontinuities, determine size, accept/reject per specified code

Passing: 70%

Certification:

Upon passing all three exams, trainee receives ASNT RT Level II course completion certificate

Employer must issue formal Level II certification per SNT-TC-1A

Certification validity: Per employer's written practice (typically 3-5 years with periodic recertification)

Learning Outcomes

Understand X-ray and gamma-ray physics and radiation interactions

Operate radiographic equipment safely and effectively

Produce quality radiographs meeting code requirements

Process radiographic film with proper density and contrast

Interpret radiographs and identify discontinuities accurately

Apply acceptance criteria from ASME, AWS, API codes

Ensure radiation safety and regulatory compliance

Pass ASNT RT Level II examinations (General, Specific, Practical)

Perform Level II RT inspections independently in GCC industries

Course Materials

ASNT Level II RT Courseware (comprehensive textbook)

ASNT SNT-TC-1A Recommended Practice

ASME Section V Article 2 (Radiographic Examination)

Code excerpts: ASME Section VIII, B31.3, AWS D1.1, API 1104

Radiograph interpretation workbook (100+ sample radiographs)

IQI sensitivity charts and exposure calculators

Radiation safety manual and regulations

RT procedure templates and report forms

Equipment & Facilities:

Industrial X-ray equipment (portable and stationary)

Gamma-ray cameras (Ir-192 sources)

Film processing room with manual and automatic processors

Densitometers and illuminators

Film library with documented discontinuities

Radiation monitoring equipment

Safety barriers and PPE

Instructor: Eng. Turki Al-Harbi, ASNT Level III RT/UT, AWS CWI, 20 years NDT, Aramco certified

Registration Information:

Session | Dates | Location | Status |

|---|---|---|---|

RT2-2025-12 | March 9-20, 2026 | Cairo | Open (12 seats) |

RT2-2026-02 | Feb 9-20, 2026 | Riyadh | Open |

RT2-2026-04 | Apr 13-24, 2026 | Dammam | Open |

Investment: 7,500 SAR (Training + exam preparation; employer certification fees separate)

Registration: scitcc.com/asnt-rt-level2 | +971-566922928