Arc Stick Welding

$5500.00

Arc Stick Welding (SMAW) Professional Training: 5-Day Intensive Certification Course

Course Overview

This comprehensive 5-day arc stick welding course provides intensive hands-on training in Shielded Metal Arc Welding (SMAW) techniques tailored for industrial applications across Saudi Arabia (KSA), Oman, UAE, Qatar, Kuwait, Bahrain, and African markets. This practical welding certification program covers electrode selection, all-position welding, pipe welding fundamentals, and AWS qualification standards essential for construction, oil and gas, structural steel fabrication, shipbuilding, and maintenance operations throughout the GCC region and Africa.

Target Audience

Entry-level welders seeking SMAW certification in KSA and GCC countries

Maintenance technicians in Saudi Aramco, ADNOC, and African industrial facilities

Construction workers transitioning to certified welding positions in Oman and UAE

Fabrication shop personnel requiring multi-position welding skills across Middle East

Pipeline welders preparing for API 1104 qualification in GCC and African projects

Military and vocational students pursuing welding careers in emerging African economies

Day 1: SMAW Equipment, Safety and Welding Fundamentals

Morning Session: Introduction to Arc Stick Welding

History and advantages of SMAW in field welding applications across GCC

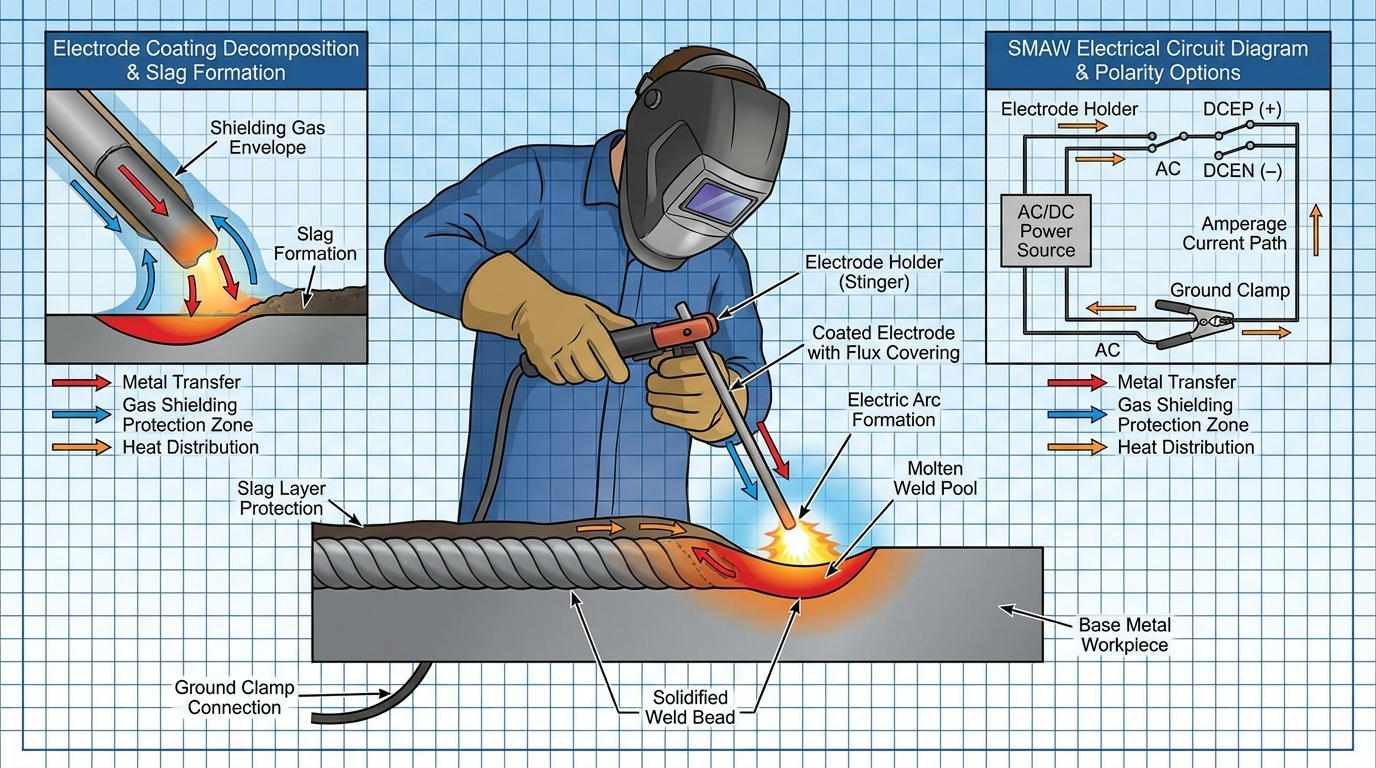

Arc welding principles: electrical circuit, arc characteristics, heat generation

Equipment components: transformer welders, inverter machines, rectifier systems

Duty cycle ratings and machine capacity selection for different applications

Power source comparison: AC vs DC welding for various electrodes and materials

Polarity effects: DCEP, DCEN, AC applications for different electrode types

Portable welding machines for remote African construction sites and desert operations

Cost-effectiveness of SMAW for small-scale workshops in developing markets

Afternoon Session: Workplace Safety and Personal Protection

Electrical safety protocols: proper grounding, cable inspection, shock prevention

Arc radiation hazards: UV protection, proper shade selection (#10-#14 lenses)

Personal Protective Equipment (PPE): welding helmets, leather gloves, protective clothing

Fire prevention measures for Saudi construction sites and African workshops

Fume extraction systems and respiratory protection requirements

Confined space welding safety in tanks and pressure vessels

Hot work permits and safety procedures per KSA labor regulations

First aid for welding injuries: burns, arc flash, electric shock treatment

OSHA compliance and GCC occupational health standards

Hands-on practice: equipment setup, electrode holder connection, ground clamp positioning

Learning Outcomes: Complete understanding of SMAW equipment operation and comprehensive safety knowledge for accident-free welding in GCC and African industrial environments.

Day 2: Electrode Classification and Flat Position Welding

Morning Session: Welding Electrode Technology

AWS A5.1 electrode classification system: E6010, E6011, E6013, E7018, E7024

Electrode numbering interpretation: tensile strength, welding position, coating type

Coating types and functions: cellulose, rutile, low-hydrogen, iron powder

E6010 applications: deep penetration for pipeline root passes and open root joints

E6011 characteristics: AC capability for farm equipment repair and maintenance welding

E6013 features: smooth arc, light slag for sheet metal fabrication and general purpose

E7018 low-hydrogen electrodes: structural steel welding meeting AWS D1.1 requirements

Electrode storage requirements: rod ovens, moisture control for low-hydrogen electrodes

Amperage selection charts for different electrode sizes and material thickness

Afternoon Session: Flat Position (1G/1F) Welding Practice

Workpiece preparation: edge preparation, fit-up, tack welding techniques

Arc striking methods: scratching vs tapping technique for stable arc initiation

Arc length control: maintaining proper electrode-to-work distance (electrode diameter)

Travel speed optimization: avoiding excessive heat input and distortion

Bead appearance criteria: uniform width, consistent ripples, proper tie-in

Stringer beads vs weave beads: application and technique differences

Multi-pass welding procedures: root, fill, and cap pass sequences

Practical exercises: running continuous beads on mild steel plates (6mm-12mm)

Defect identification: porosity, undercut, overlap, slag inclusion recognition

Quality assessment: visual inspection per ASME Section IX acceptance criteria

Learning Outcomes: Proficiency in electrode selection and flat position welding techniques forming the foundation for advanced positional welding in GCC fabrication shops.

Day 3: Horizontal and Vertical Position Welding Techniques

Morning Session: Horizontal Position (2G/2F) Welding

Joint configurations: butt joints, fillet joints, lap joints in horizontal orientation

Electrode angle techniques: work angle (0-15°) and travel angle (10-15°)

Gravity effects management: preventing sag and overlap on horizontal surfaces

Current adjustment for horizontal welding: typically 5-10% reduction from flat position

Multi-pass horizontal groove welding: shelf technique for thick plate applications

Horizontal fillet welds: building proper leg size for structural steel connections

Applications: I-beams, box columns, pressure vessel circumferential seams

Hands-on practice: 2G butt joint qualification on 10mm carbon steel plates

Inspection techniques: fillet weld gauges, visual examination standards

Afternoon Session: Vertical Position (3G/3F) Welding

Vertical-up vs vertical-down welding: technique selection criteria

E6010/E6011 vertical-down: high-speed travel for sheet metal and pipe hot passes

E7018 vertical-up technique: weaving patterns (triangular, Z-weave, C-weave)

Keyhole method for vertical-up root passes in groove welds

Electrode manipulation: pausing at toes, quick movement through center

Heat control strategies: preventing burn-through while ensuring adequate fusion

Vertical fillet welds: building consistent leg size throughout weld length

Critical applications: high-rise construction in Saudi Arabia and UAE skyscrapers

Extensive practice: 3G butt joint welding on structural steel plates

Performance testing: bend test specimen preparation for ductility verification

Learning Outcomes: Mastery of horizontal and vertical welding positions essential for 70% of welding applications in GCC construction and African infrastructure projects.

Day 4: Overhead Welding and Pipe Welding Fundamentals

Morning Session: Overhead Position (4G/4F) Welding

Overhead welding challenges: molten metal control, slag management, safety concerns

Body positioning and ergonomics: minimizing fatigue during overhead operations

Electrode size selection: typically smaller diameter (2.5mm-3.2mm) for better control

Current reduction: 10-15% lower amperage preventing excessive droplet size

Short arc technique: tight arc length preventing large molten pool formation

Stringer beads preference: narrow beads reducing slag trapping risk

Overhead fillet welds: critical for structural connections and underside repairs

Applications: tank bottom repairs, overhead piping, bridge understructures

Practical exercises: 4G groove weld qualification on carbon steel test plates

Welding overhead safely: preventing hot metal and slag from falling on welder

Afternoon Session: Pipe Welding Introduction (5G Position)

Pipe welding importance in GCC oil and gas infrastructure and African pipelines

Pipe joint preparation: beveling, land thickness, root opening requirements

Root pass techniques: E6010 open root keyhole method for complete penetration

Fixed pipe (5G) welding sequence: 12 o’clock to 6 o’clock, alternating sides

Hot pass application: E6010/E6011 fast travel speed removing slag and oxidation

Fill and cap passes: E7018 low-hydrogen electrodes for structural integrity

API 1104 qualification requirements for pipeline construction certification

Pipeline welding career opportunities: Saudi Aramco projects, African gas pipelines

Hands-on practice: 5G position on 4-inch schedule 40 carbon steel pipe

Visual inspection criteria: uniform bead profile, proper reinforcement, no defects

Learning Outcomes: Complete all-position welding capability and introduction to high-demand pipe welding skills for GCC petrochemical and African energy sector employment.

Day 5: Welding Qualification Testing and Career Development

Morning Session: AWS and ASME Qualification Testing

Welding Procedure Specification (WPS): understanding essential variables

Performance Qualification Test (PQT): test plate/pipe setup and execution

Welder qualification ranges: thickness, diameter, position qualified by single test

Bend test procedures: guided bend test fixture, acceptance criteria

Visual examination standards: undercut limits, porosity size, crack prohibition

Radiographic testing basics: understanding RT film interpretation for welds

Qualification documentation: welder performance qualification (WPQ) records

Requalification requirements: 6-month activity rule, code changes, essential variable changes

Mock qualification test: simulated AWS D1.1 3G test plate welding and evaluation

International certifications: CSWIP, CWB, TÜV recognition across global markets

Afternoon Session: Advanced Applications and Career Pathways

Specialized SMAW applications: cast iron repair, hard surfacing, dissimilar metals

Welding in extreme conditions: high winds (desert), high humidity (coastal GCC)

Maintenance and repair welding: equipment breakdown response in African mining

Welding job market analysis: salary expectations in KSA (SAR 4,000-12,000/month)

Career progression paths: welder → lead welder → welding inspector → welding supervisor

Entrepreneurship opportunities: starting mobile welding services in Oman and Africa

Continuing education: TIG welding, MIG welding, pipe welding specialization courses

Employer requirements: Saudi Aramco approved welder list, ADNOC contractor qualification

Job placement assistance: connections with GCC fabrication companies and African contractors

Final practical assessment and course certification ceremony

Learning Outcomes: Job-ready SMAW welding skills with clear understanding of qualification requirements and career opportunities in booming GCC and African industrial markets.

Course Benefits for GCC and African Markets

✓ 90% hands-on training with industrial-grade equipment used in KSA and UAE facilities

✓ AWS D1.1 qualification test preparation for immediate employment eligibility

✓ All-position welding competency (1G through 5G) for versatile job applications

✓ Bilingual instruction (English/Arabic) for accessibility across Middle East

✓ Job placement assistance with leading contractors in Saudi Arabia, Oman, Qatar

✓ Industry-recognized certification accepted across GCC countries and African markets

✓ Small class sizes (maximum 8 students per instructor) ensuring personalized attention

✓ Lifetime technical support and refresher training opportunities

Investment in High-Demand Skills

Arc stick welding remains the most versatile and widely used welding process across Saudi Arabia’s construction boom, Oman’s infrastructure development, UAE’s industrial expansion, and Africa’s rapid industrialization. With Vision 2030 megaprojects in KSA and massive infrastructure investments across Africa, demand for certified SMAW welders has never been higher. Graduates earn competitive salaries and enjoy excellent job security in oil and gas, construction, shipyards, power plants, and manufacturing facilities.

Enroll today to master the most essential welding skill and launch your career in the thriving GCC and African industrial sectors!

Keywords: stick welding course KSA, SMAW training Saudi Arabia, arc welding certification Oman, stick welding jobs GCC, arc welder training Africa, AWS welding qualification Middle East, E7018 electrode training, pipe welding course Gulf, structural welding certification, Saudi Aramco welder qualification, ADNOC welding jobs, stick welding training UAE, certified welder Africa, welding courses Qatar Kuwait Bahrain, pipeline welding career, SMAW certification program