API 682 : Pumps - Shaft Sealing Systems for Centrifugal and Rotary Pumps

$5500.00

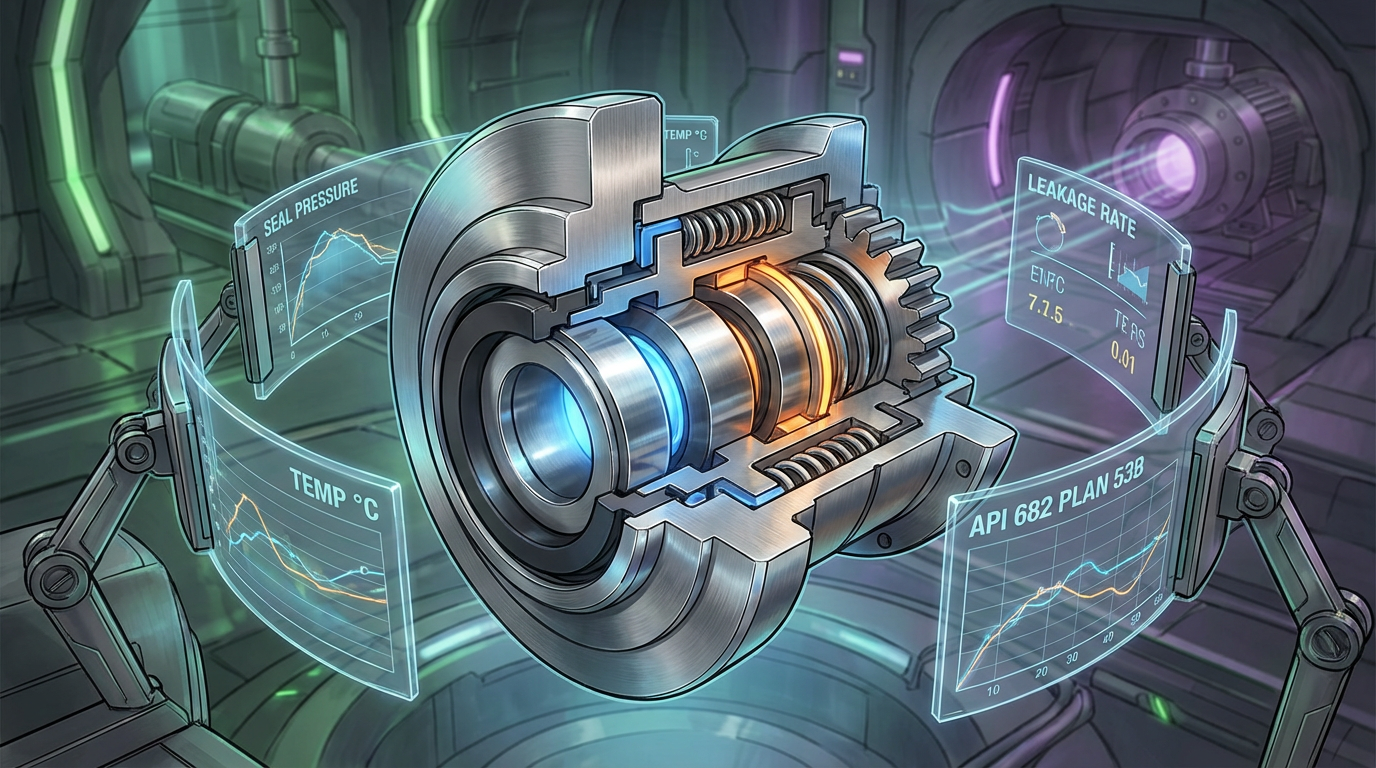

API 682 - Shaft Sealing Systems for Centrifugal and Rotary Pumps

5-Day Professional Training Course

Course Overview

This intensive 5-day API 682 training course provides comprehensive knowledge of mechanical seal systems for centrifugal and rotary pumps according to API Standard 682 (5th Edition). The course covers seal design, selection, installation, operation, troubleshooting, and maintenance of shaft sealing systems in process industries.

Target Audience: Mechanical engineers, reliability engineers, maintenance engineers, pump engineers, rotating equipment specialists, seal technicians, plant engineers, and professionals responsible for pump sealing systems in oil & gas, petrochemical, chemical processing, and power generation industries.

Day 1: Fundamentals and API 682 Overview

Morning Session (0900-1230)

Module 1: Course Introduction & Sealing Fundamentals

Course objectives and structure

Introduction to shaft sealing technology

History and evolution of mechanical seals

Why seals fail: common causes and statistics

Economic impact of seal failures

Safety and environmental considerations

Module 2: API 682 Standard Overview

API 682 5th Edition (2021) structure and scope

Purpose and applicability

Key changes from 4th Edition

Integration with API 610 (Centrifugal Pumps)

Integration with API 676 (Rotary Pumps)

Terminology and definitions

Compliance requirements

Documentation and data sheets

Afternoon Session (1330-1700)

Module 3: Mechanical Seal Design Principles

Basic seal components and nomenclature

Seal face materials (carbon, silicon carbide, tungsten carbide, ceramics)

Secondary sealing elements (O-rings, gaskets, wedges)

Seal face loading mechanisms

Balance ratio and closing forces

Heat generation and dissipation

PV (Pressure-Velocity) limits

Lubrication regimes (boundary, mixed, hydrodynamic)

Face geometry and flatness requirements

Module 4: Seal Configuration Types

Single seals: Inside/outside mounted, pusher/non-pusher

Dual seals: Back-to-back, face-to-face, tandem arrangements

Cartridge seals: Benefits and applications

Component seals vs. cartridge seals

Split seals for repair without pump disassembly

Mixing device seals

Seal selection criteria based on service conditions

Day 2: API 682 Seal Arrangements and Plans

Morning Session (0900-1230)

Module 5: API 682 Seal Arrangements

Arrangement 1: Single seal - unpressurized

Arrangement 2: Single seal - pressurized

Arrangement 3: Dual seal - pressurized barrier fluid

Arrangement 4: Dual seal - unpressurized buffer fluid (API 682 5th Edition)

Selection criteria for each arrangement

Application guidelines

Advantages and limitations

Cost-benefit analysis

Module 6: API 682 Piping Plans (Part 1)

Overview of API 682 piping plans

Plan 01: Recirculation from seal chamber

Plan 02: Dead-ended seal chamber

Plan 11: Recirculation from pump discharge

Plan 13: Recirculation from pump discharge with cyclone separator

Plan 14: Recirculation with external heat exchanger

Plan 21: Recirculation from seal chamber with heat exchanger

Plan 23: Recirculation from pump discharge with heat exchanger

Plan 31: Recirculation with internal cyclone separator

Afternoon Session (1330-1700)

Module 7: API 682 Piping Plans (Part 2)

Plan 32: External flush from external source

Plan 41: Circulating throat bushing

Plan 52: Unpressurized buffer fluid for dual seals (Arrangement 4)

Plan 53: Pressurized barrier fluid with bladder accumulator (Arrangement 3)

Plan 54: Pressurized barrier fluid with external reservoir (Arrangement 3)

Plan 72: Quench/steam connections

Plan 74: Vent/drain connections

Piping plan selection methodology

Fluid compatibility considerations

Material selection for plan components

Workshop 1: Seal Arrangement and Piping Plan Selection Exercise

Given process conditions, select appropriate arrangement

Design piping plan for specific applications

Calculate flow rates and heat loads

Day 3: Design, Materials, and Installation

Morning Session (0900-1230)

Module 8: Seal Support Systems Design

Heat exchangers: Sizing, selection, tube vs. plate type

Reservoirs/accumulators: Volume calculations, level monitoring

Cyclone separators: Function and sizing

Thermosiphon systems: Natural circulation principles

Pumped circulation systems: External pumps

Control and monitoring instrumentation:

Pressure gauges and transmitters

Temperature sensors

Flow indicators

Level switches

Barrier/buffer fluid quality monitoring

Module 9: Materials Selection

Seal face materials:

Carbon grades (resin impregnated, antimony, metal filled)

Silicon carbide (reaction bonded, sintered, converted)

Tungsten carbide (nickel binder, cobalt binder)

Ceramics (alumina, zirconia)

Material pairing compatibility

Elastomers and secondary seals:

Nitrile (NBR), FKM (Viton), EPDM, Kalrez, PTFE

Chemical compatibility

Temperature limits

Metallic components: Stainless steels, Hastelloy, titanium, Monel

Material selection based on process chemistry

Afternoon Session (1330-1700)

Module 10: Installation and Commissioning

Pre-installation inspection checklist

Seal installation procedures

Critical installation parameters:

Seal chamber dimensions and tolerances

Shaft runout and end play limits (API 610 requirements)

Seal face perpendicularity

Compression settings for pusher seals

Torque specifications

Support system installation

Pressure testing procedures

Flushing and priming systems

Pre-commissioning checks

Start-up procedures and monitoring

Run-in period considerations

Module 11: Operation and Maintenance

Operating envelope and limits

Monitoring parameters (temperature, pressure, leakage)

Normal vs. abnormal operation indicators

Planned maintenance activities

Seal life expectancy factors

Spare parts management

Documentation and record keeping

Mean Time Between Failures (MTBF) tracking

Workshop 2: Installation Procedure Development

Create installation procedure for specific seal

Identify critical measurements

Develop checklist

Day 4: Troubleshooting and Failure Analysis

Morning Session (0900-1230)

Module 12: Seal Failure Modes and Root Cause Analysis

Common failure modes:

Face wear (excessive, uneven)

Thermal cracking and heat checking

Face chipping and fracture

Secondary seal extrusion

Elastomer deterioration

Corrosion and erosion

Coking and product buildup

Crystallization

Root cause analysis methodology:

Data collection and documentation

Visual inspection techniques

Face pattern analysis

Measurement and dimensional checks

Process condition review

Operating history analysis

Module 13: Troubleshooting Guide

Excessive leakage:

Causes: face damage, improper installation, process upsets

Diagnostic approach

Corrective actions

High seal temperatures:

Inadequate cooling/lubrication

Support system failures

Solutions and preventive measures

Short seal life:

Process-related causes

Design inadequacies

Installation errors

Vibration and noise:

Seal hang-up

Cavitation effects

Pump/driver issues

Premature wear:

Abrasive particles

Dry running

Chemical attack

Afternoon Session (1330-1700)

Module 14: Advanced Troubleshooting

Process condition impacts:

Temperature excursions

Pressure fluctuations

Cavitation and flashing

Solids content and particle size

Polymerization and product fouling

Deadheading and low flow

Support system problems:

Heat exchanger fouling

Reservoir contamination

Blocked piping plans

Instrumentation failures

Barrier fluid degradation

Pump-related issues affecting seals:

Excessive shaft deflection

Bearing problems

Impeller imbalance

Cavitation

Module 15: Case Studies - Seal Failures

Refinery case studies

Chemical plant incidents

Offshore platform experiences

Root cause analysis examples

Lessons learned and best practices

Cost of failures vs. prevention

Workshop 3: Failure Analysis Exercise

Analyze actual seal failure photographs

Determine root causes

Recommend corrective actions

Group presentations

Day 5: Special Applications and Performance Optimization

Morning Session (0900-1230)

Module 16: Special Service Applications

High temperature services (>300°C/570°F):

Design considerations

Cooling requirements

Material selection

Cryogenic services (<-40°C/-40°F):

Low temperature materials

Thermal management

High pressure services (>150 bar/2200 psi):

Seal face loading

Balance ratio optimization

Slurry and solids handling:

Flush plans for particle removal

Wear-resistant materials

Seal face designs

Polymer and crystallizing services:

Prevention of product buildup

Heating and quench systems

Hydrocarbon and light ends:

Vapor pressure considerations

Cooling requirements

Corrosive chemicals:

Material compatibility

Special alloys

Module 17: Gas Seals and Dry Running Seals

Dry gas seals:

Operating principles

Applications in compressors and pumps

Support systems

Non-contacting seals:

Lift-off mechanisms

Groove patterns

Comparison with conventional mechanical seals

Selection criteria

Afternoon Session (1330-1700)

Module 18: Performance Optimization and Reliability

Reliability engineering approach:

Failure rate analysis

Weibull analysis for seal life

Reliability centered maintenance (RCM)

Condition-based monitoring

Seal testing and qualification:

API 682 qualification testing requirements

Performance testing procedures

Acceptance criteria

Upgrading existing installations:

Evaluation criteria

Retrofit considerations

Cost justification

Emerging technologies:

Magnetic drive pumps (seal-less)

Canned motor pumps

Advanced seal face coatings

Smart seals with sensors

Digital twins and predictive analytics

Module 19: Specifications and Procurement

Writing seal specifications

API 682 data sheet preparation

Vendor selection criteria

Technical bid evaluation

Quality assurance requirements

Factory acceptance testing (FAT)

Spare parts recommendations

Module 20: Course Review and Assessment

Key learning points summary

API 682 quick reference guide

Best practices checklist

Interactive Q&A session

Final Examination: 60 questions, 2 hours, 70% passing score

Course evaluation

Certificate presentation

Post-course support information

Learning Outcomes

Upon completion, participants will be able to:

✅ Understand API 682 standard requirements and applications

✅ Select appropriate seal arrangements for various services

✅ Design and specify piping plans for seal support systems

✅ Specify materials based on process conditions

✅ Install mechanical seals correctly per API standards

✅ Troubleshoot seal failures and identify root causes

✅ Optimize seal performance and extend seal life

✅ Develop maintenance strategies for sealing systems

✅ Evaluate and specify seal systems for new applications

✅ Improve pump reliability through proper seal management