API 571 - Corrosion & Materials (Damage Mechanisms)

$1500.00

API 571 - Corrosion & Materials (Damage Mechanisms)

Course Overview

Program Title: API 571 Damage Mechanisms Affecting Fixed Equipment in Refining Industry

Duration: 3 Days (24 Contact Hours)

Schedule: January 20-22, 2026 | March 17-19, 2026

Timing: Full-Day (9:00 AM - 5:00 PM)

Location: Riyadh, Dammam | Online Live

Course Code: STC-API571-2026-01

Investment: 2,800 SAR (Early Bird: 2,240 SAR)

Course Description:

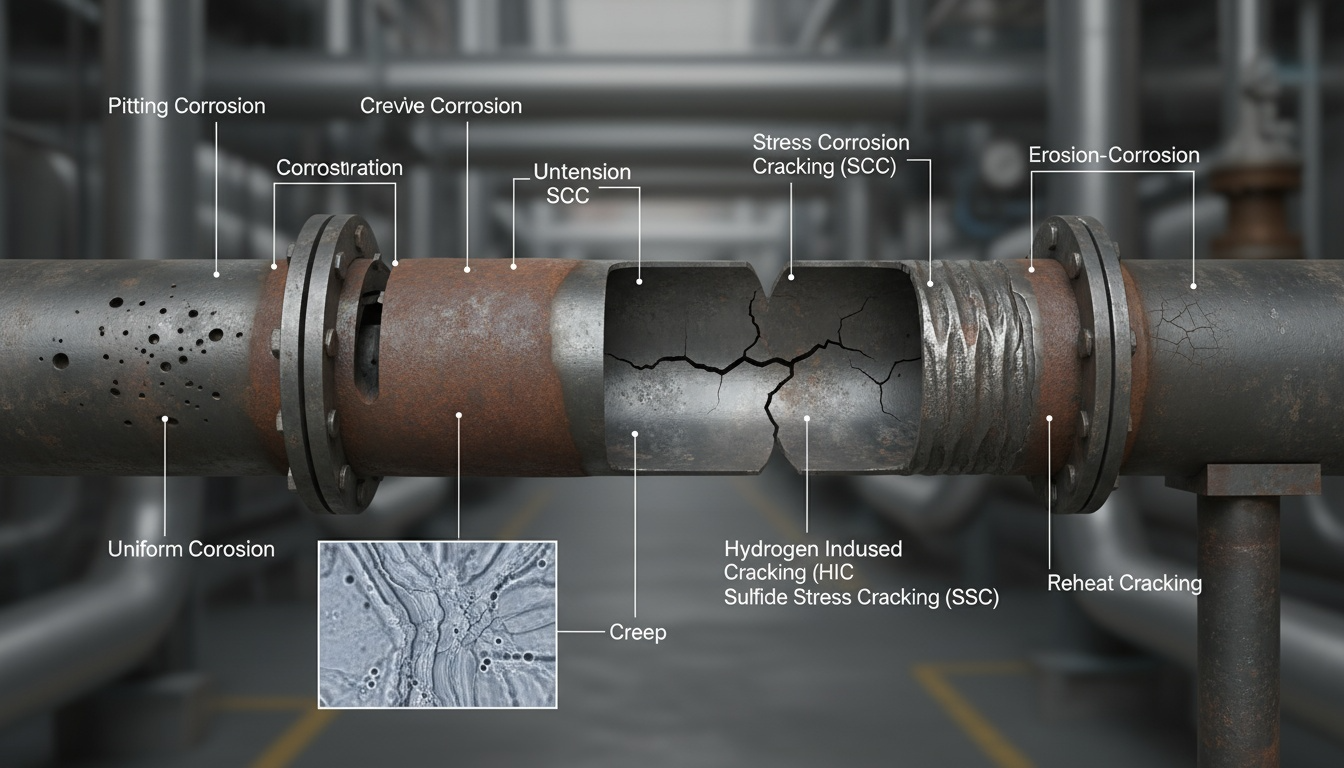

Comprehensive training on API 571 Damage Mechanisms covering 65+ degradation modes affecting pressure vessels, piping, and tanks in refining and petrochemical operations. Essential knowledge for API 510/570/653 inspectors, corrosion engineers, and integrity specialists in GCC facilities.

Course covers metallurgy fundamentals, corrosion theory, environment-specific damage mechanisms (crude units, cat crackers, hydrocrackers, reformers), cracking mechanisms, high-temperature damage, inspection techniques, and mitigation strategies.

Target Audience:

API 510/570/653 inspectors seeking advanced knowledge

Corrosion engineers and materials specialists

Inspection engineers and RBI coordinators

Mechanical integrity engineers

Plant engineers and operations personnel

NACE corrosion technologists

Prerequisites:

Basic understanding of refinery/petrochemical processes

Familiarity with inspection practices

Engineering or technical background preferred

Course Curriculum Highlights

Day 1: Metallurgy & General Corrosion Mechanisms

Metallurgy fundamentals: Crystal structure, phases, heat treatment

Carbon steel, stainless steel, nickel alloys properties

Corrosion theory: Electrochemical reactions, galvanic series

General/uniform corrosion

Galvanic corrosion

Pitting and crevice corrosion

Erosion and erosion-corrosion

Cavitation damage

Atmospheric corrosion

Corrosion under insulation (CUI/CUFI)

Day 2: Environment-Specific Corrosion & Cracking

Sulfidic corrosion (H2S, sulfidation, polythionic acid)

Naphthenic acid corrosion

Amine corrosion (DEA, MEA, MDEA systems)

Caustic corrosion and caustic stress corrosion cracking

Sour water corrosion

Hydrofluoric acid corrosion (HF alkylation units)

Chloride stress corrosion cracking (CSCC)

Hydrogen-induced cracking (HIC, SOHIC, SSC)

Ammonia stress corrosion cracking

Carbonate cracking

Day 3: High-Temperature Damage & Mechanical Mechanisms

High-temperature hydrogen attack (HTHA) - Nelson curves

High-temperature oxidation and scaling

Carburization and metal dusting

Nitriding

Graphitization of carbon steel

885°F (475°C) embrittlement

Sigma phase embrittlement

Temper embrittlement

Creep and stress rupture

Thermal fatigue and mechanical fatigue

Brittle fracture

Erosion mechanisms in specific unit operations

Damage mechanism matrix for refinery units

Learning Outcomes

Identify 65+ damage mechanisms per API 571

Understand root causes and contributing factors

Recognize susceptible materials and environments

Apply inspection techniques for detection

Implement mitigation and prevention strategies

Support RBI program development with damage mechanism knowledge

Enhance API 510/570/653 certification performance

Course Materials

API 571 Damage Mechanisms (2nd Edition) - full copy provided

Course workbook with photos and case studies

Damage mechanism matrix for GCC refinery units

Visual identification guide (500+ photos)

Quick reference cards by unit operation

Instructor: Dr. Tariq Al-Harbi, PhD Metallurgy, NACE Fellow, 25 years Aramco R&D

Registration: scitcc.com/api-571 | +971566922928