Ammonia Awareness Training

$5500.00

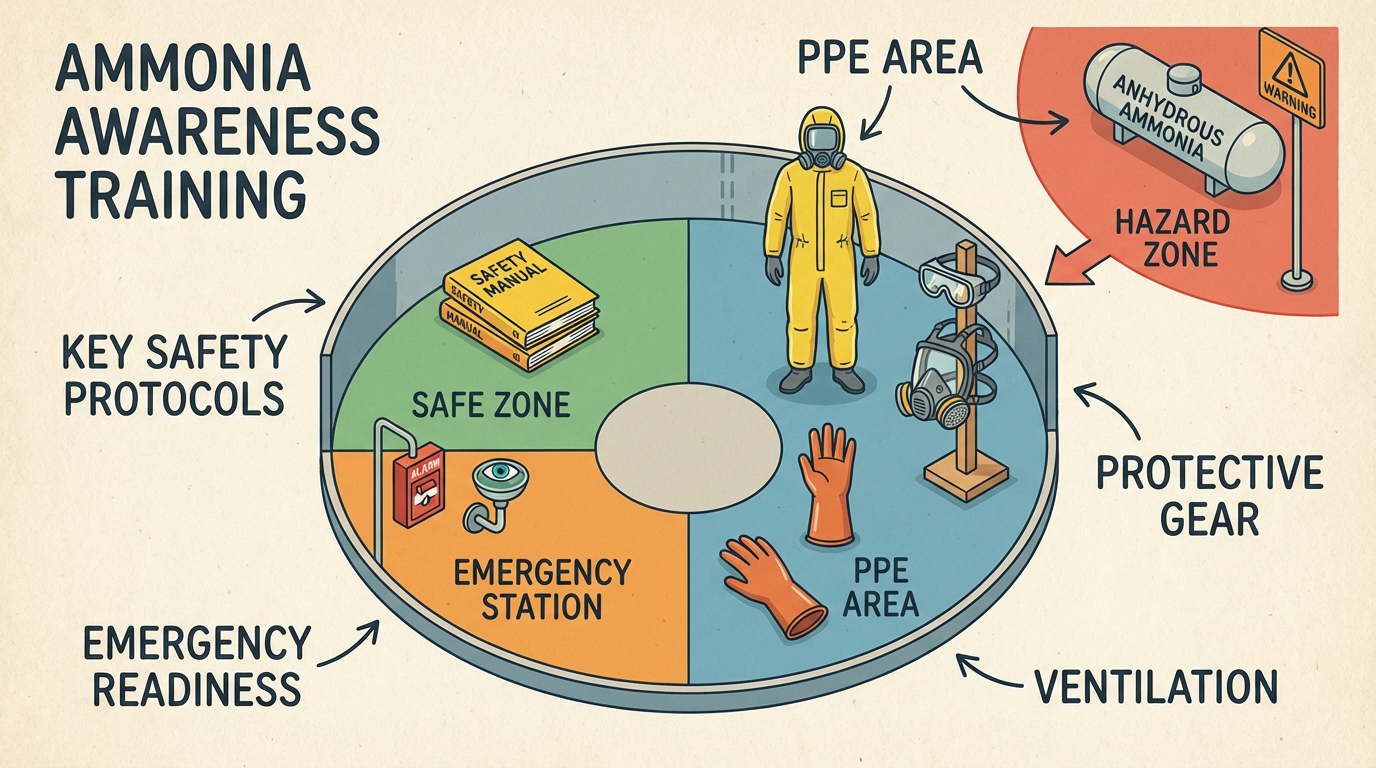

Ammonia Awareness Training: 5-Day Comprehensive Safety Course

Course Overview

This intensive 5-day ammonia awareness training provides comprehensive knowledge of ammonia properties, hazards, safe handling practices, and emergency response procedures. Designed for workers in ammonia production, refrigeration, fertilizer manufacturing, and any facility handling anhydrous or aqueous ammonia, this course ensures workplace safety and regulatory compliance.

Target Audience: Plant operators, maintenance technicians, safety officers, emergency responders, supervisors, warehouse workers, refrigeration technicians, and anyone working near ammonia systems or storage facilities.

Course Objectives:

Understand ammonia physical and chemical properties

Recognize ammonia hazards and health effects

Apply safe work practices and procedures

Use personal protective equipment correctly

Respond effectively to ammonia emergencies

Comply with OSHA and EPA regulations

Day 1: Ammonia Properties and Hazard Recognition

Morning Session: Introduction to Ammonia

Understanding Ammonia Fundamentals

Foundation knowledge of ammonia characteristics:

Physical and Chemical Properties:

Chemical formula: NH₃

Colorless gas with pungent, suffocating odor

Boiling point: -33.3°C (-28°F) at atmospheric pressure

Vapor density: lighter than air (0.6 relative to air)

Solubility: highly soluble in water

Flammability range: 15-28% in air (narrow range)

Auto-ignition temperature: 651°C (1204°F)

Molecular weight: 17.03 g/mol

Ammonia Forms and Applications:

Anhydrous ammonia: 99.5%+ pure, liquefied under pressure

Aqueous ammonia: 5-30% solutions in water

Industrial applications: fertilizers, refrigeration, chemicals

Production processes: Haber-Bosch synthesis

Global usage and economic importance

Storage and transportation methods

Why Ammonia Is Hazardous:

High toxicity and reactivity

Corrosive to tissues

Flammable and explosive potential

Pressure hazards in storage systems

Environmental impact of releases

Afternoon Session: Health Hazards and Exposure

Ammonia Health Effects

Understanding health risks and exposure limits:

Routes of Exposure:

Inhalation: primary route of exposure

Eye contact: severe damage risk

Skin contact: chemical burns

Ingestion: rare but extremely dangerous

Acute Health Effects:

Irritation: eyes, nose, throat at low concentrations

Respiratory effects: coughing, bronchospasm, pulmonary edema

Eye damage: corneal burns, permanent vision loss

Skin burns: chemical burns, blistering

Systemic effects: shock, cardiovascular collapse

Concentration-dependent severity

Exposure Limits:

OSHA PEL: 50 ppm (8-hour TWA)

NIOSH REL: 25 ppm (10-hour TWA)

STEL (Short-Term Exposure Limit): 35 ppm

IDLH (Immediately Dangerous to Life/Health): 300 ppm

Odor threshold: 5-50 ppm (varies by individual)

Lethal concentration: 5,000+ ppm for 30 minutes

Chronic Health Effects:

Chronic bronchitis and asthma

Permanent eye damage

Skin sensitization

Respiratory system damage

Long-term exposure consequences

Vulnerable Populations:

Pre-existing respiratory conditions

Pregnant workers

Workers with eye disorders

Skin condition sensitivities

Day 2: Safe Work Practices and Procedures

Morning Session: Engineering and Administrative Controls

Controlling Ammonia Exposure

Implementing hierarchy of controls:

Engineering Controls:

Closed-loop systems: primary containment

Ventilation systems: local exhaust and general

Gas detection and alarm systems

Emergency shutdown systems

Pressure relief devices

Secondary containment and dikes

Scrubber systems for emissions

Administrative Controls:

Standard operating procedures (SOPs)

Permit-to-work systems: hot work, confined space

Lockout/tagout (LOTO) procedures

Training and competency requirements

Buddy system for high-risk activities

Work schedules and exposure time limits

Medical surveillance programs

Safe Work Practices:

Pre-job safety briefings and JSAs

Area inspection before work

Proper tool and equipment selection

Communication protocols

Housekeeping and leak prevention

Equipment inspection and maintenance

Incident reporting procedures

Afternoon Session: Personal Protective Equipment

PPE Selection and Use

Mastering personal protective equipment:

Respiratory Protection:

Air-purifying respirators: cartridge types and limitations

Supplied-air respirators: airline systems

Self-contained breathing apparatus (SCBA): emergency use

Fit testing requirements and frequency

Cartridge change-out schedules

Proper donning and doffing procedures

Limitations and breakthrough times

Eye and Face Protection:

Chemical splash goggles

Full-face shields for severe exposure risk

Contact lens restrictions

Anti-fog treatments and maintenance

Emergency eyewash station locations

Skin Protection:

Chemical-resistant gloves: neoprene, butyl rubber

Chemical suits for major exposures

Boots and footwear requirements

Proper selection based on concentration

Decontamination procedures

PPE inspection and replacement

PPE Maintenance:

Cleaning and storage procedures

Inspection before each use

Replacement criteria and schedules

Documentation and record-keeping

Day 3: Ammonia Systems and Equipment

Morning Session: Storage and Handling Systems

Understanding Ammonia Equipment

Knowledge of ammonia systems:

Storage Systems:

Refrigerated atmospheric storage: large-scale facilities

Pressurized storage: bullets, spheres, cylinders

Tank design: ASME codes and standards

Capacity ranges and typical configurations

Insulation and refrigeration systems

Instrumentation: level, pressure, temperature

Piping and Transfer Systems:

Piping materials: carbon steel, stainless steel

Valve types: manual, automatic, emergency

Transfer pumps and compressors

Hoses and flexible connections

Loading/unloading systems

Vapor return lines and recovery

Safety Systems:

Pressure relief valves (PRVs)

Emergency isolation valves

Gas detection systems: fixed and portable

Water deluge and spray systems

Emergency shutdown (ESD) systems

Alarms and notification systems

Afternoon Session: Refrigeration Systems

Ammonia Refrigeration

Understanding ammonia refrigeration applications:

Refrigeration System Components:

Compressors: reciprocating, screw, centrifugal

Condensers and evaporators

Receiver vessels and accumulators

Expansion valves and controls

Oil separators and purge systems

Defrost systems and procedures

Operating Procedures:

Normal startup and shutdown

Capacity control and optimization

Oil management and removal

Defrost cycle operations

Monitoring and trending parameters

Abnormal condition recognition

IIAR Standards:

IIAR 2: Equipment, Design, and Installation

IIAR 3: Ammonia Refrigeration Valves

IIAR 4: Installation of Closed-Circuit Ammonia Refrigeration Systems

IIAR 6: Inspection, Testing, and Maintenance

Compliance requirements and audits

Day 4: Emergency Response and Preparedness

Morning Session: Leak Detection and Response

Recognizing and Responding to Releases

Mastering emergency response:

Leak Detection Methods:

Odor recognition (unreliable at high concentrations)

Fixed gas detection systems: electrochemical, infrared

Portable gas monitors and detectors

Visual indicators: vapor clouds, ice formation

Audible indicators: hissing, pressure release

Monitoring system alarms

Emergency Response Priorities:

Life safety first: evacuation and rescue

Property protection secondary

Environmental protection

Incident command structure

Communication and notifications

Resource mobilization

Immediate Actions:

Activate emergency alarm systems

Evacuate affected areas immediately

Account for personnel at muster points

Call emergency services (911)

Notify plant emergency response team

Isolate leak source if safe to do so

Activate water deluge systems

Personal Protective Actions:

Move upwind, uphill, and upstream

Seek shelter indoors with closed windows

Shelter-in-place procedures

Evacuation routes and assembly points

Communication during emergencies

Afternoon Session: Emergency Procedures

Emergency Management

Implementing response procedures:

Spill and Leak Response:

Small leak containment procedures

Large release evacuation zones

Water spray curtains for vapor suppression

Dilution with water (if safe and appropriate)

Isolation valve operation

Remote shutdown procedures

Fire Response:

Ammonia fire characteristics

Appropriate extinguishing agents

Let fire burn if stopping flow not possible

Cool surrounding containers

Withdraw if storage tanks involved

Firefighting tactics and safety zones

First Aid and Medical Response:

Remove victim from exposure immediately

Fresh air and rest

Eye irrigation: 15+ minutes with water

Skin washing: remove contaminated clothing

CPR if breathing stopped

Seek immediate medical attention

Never give anything by mouth to unconscious victim

Decontamination:

Emergency shower and eyewash use

Clothing removal and disposal

Equipment decontamination

Area cleanup and restoration

Waste disposal requirements

Day 5: Regulatory Compliance and Practical Exercises

Morning Session: Regulations and Standards

Legal Requirements

Understanding regulatory compliance:

OSHA Requirements:

29 CFR 1910.111: Storage and Handling of Anhydrous Ammonia

29 CFR 1910.119: Process Safety Management (PSM)

29 CFR 1910.134: Respiratory Protection

29 CFR 1910.146: Permit-Required Confined Spaces

29 CFR 1910.1200: Hazard Communication

Recordkeeping and documentation

EPA Requirements:

Risk Management Program (RMP): 40 CFR Part 68

Clean Air Act regulations

Emergency Planning and Community Right-to-Know Act (EPCRA)

Release reporting requirements (CERCLA)

Tier II reporting

Emergency action plans

DOT Regulations:

Transportation of ammonia: 49 CFR

Container specifications and placarding

Driver training requirements

Shipping papers and manifests

Emergency response information

Industry Standards:

ANSI/IIAR standards for ammonia refrigeration

ASME codes for pressure vessels

API standards (where applicable)

NFPA 58: Liquefied Petroleum Gas Code

Afternoon Session: Practical Exercises

Hands-On Training

Applying knowledge through practice:

PPE Donning and Doffing:

Proper respirator fit testing

SCBA operation practice

Chemical suit donning sequence

Decontamination procedures

Emergency equipment removal

Gas Detection Practice:

Operating portable gas monitors

Interpreting readings and alarms

Calibration and bump testing

Response to detection alarms

Multi-gas meter operations

Emergency Scenarios:

Simulated leak detection and response

Evacuation drills and procedures

First aid scenario practice

Emergency communication exercises

Tabletop emergency exercises

Incident command practice

Equipment Demonstrations:

Emergency shutdown system activation

Valve isolation procedures

Water deluge system operation

Eyewash and safety shower use

Fire extinguisher operation

Course Assessment:

Written examination on ammonia awareness

Practical skills evaluation

Emergency scenario response test

Certificate of completion issuance

Course Deliverables

Participants Receive:

Comprehensive ammonia safety manual

Quick reference cards for emergencies

PPE selection guide

Emergency response procedures

Regulatory compliance checklist

Certificate of completion (valid 3 years)

Wallet card for ammonia awareness training

Interactive Components:

Hands-on PPE practice

Gas detection equipment operation

Emergency drill participation

Group scenario discussions

Video demonstrations

Why This Training Is Critical

Key Benefits:

Prevent ammonia-related injuries and fatalities

Ensure regulatory compliance (OSHA, EPA)

Reduce liability and insurance costs

Improve emergency preparedness

Build safety culture and awareness

Protect community and environment

Legal Requirements:

OSHA mandates training for ammonia workers

PSM and RMP compliance requires documentation

Annual refresher training recommended

Site-specific training supplements