Advanced Concrete Technology

$5500.00

Advanced Concrete Technology: 5-Day Technical Training Course

Course Overview

This comprehensive 5-day advanced training program provides in-depth technical knowledge of modern concrete technology, covering materials science, mix design, production, placement, testing, and troubleshooting. Designed for civil engineers, structural engineers, concrete technologists, quality control managers, construction managers, and ready-mix professionals, this course combines theoretical principles with practical applications to ensure high-performance concrete construction and problem-solving capabilities.

Target Audience: Concrete technologists, civil/structural engineers, quality control managers, construction engineers, ready-mix plant managers, laboratory technicians, architects, and construction professionals working with concrete.

Day 1: Concrete Materials Science & Chemistry

Morning Session: Cement Chemistry & Hydration (9:00 AM - 12:00 PM)

Understanding Concrete at Molecular Level:

Exploring cement chemistry, hydration reactions, and microstructure development that determine concrete properties and long-term performance.

Fundamental Concepts:

Portland cement manufacturing and types (Type I through V)

Chemical composition: C3S, C2S, C3A, C4AF compounds

Hydration process and heat of hydration

Calcium Silicate Hydrate (C-S-H) gel formation

Microstructure development and pore structure

Setting and hardening mechanisms

Blended cements: fly ash, slag, silica fume, calcined clay

Supplementary Cementitious Materials (SCMs) reactions

Alkali-silica reaction (ASR) fundamentals

Sulfate attack mechanisms

Carbonation and chloride penetration

Afternoon Session: Aggregates, Water & Chemical Admixtures (1:00 PM - 5:00 PM)

Material Selection for Performance:

Mastering aggregate properties, water quality requirements, and chemical admixtures that optimize concrete performance for specific applications.

Key Topics:

Aggregate characteristics: gradation, shape, texture, strength

Coarse and fine aggregate specifications (ASTM C33)

Deleterious materials and contamination issues

Aggregate reactivity: ASR, ACR testing and prevention

Recycled aggregates and sustainability considerations

Water quality and impurity effects on concrete

Water-cement ratio relationship and Abrams’ law

Chemical admixtures: types and mechanisms

Water reducers, superplasticizers, and HRWR

Retarders, accelerators, and air-entraining agents

Shrinkage reducers and corrosion inhibitors

Viscosity modifying agents (VMA)

Admixture compatibility and interactions

Laboratory Session: Aggregate testing demonstrations and admixture dosage calculations

Day 2: Concrete Mix Design & Proportioning

Morning Session: Mix Design Methodologies (9:00 AM - 12:00 PM)

Engineering Optimal Mixtures:

Mastering systematic mix design approaches including ACI 211, British DOE method, and performance-based design to achieve target properties economically.

Mix Design Essentials:

ACI 211.1 absolute volume method

Water-cement ratio selection for strength and durability

Aggregate proportioning and optimization

Air content requirements for freeze-thaw resistance

Slump and workability targets

Statistical analysis and standard deviation

Trial batch procedures and adjustments

Cost optimization strategies

Mixture proportioning software tools

Quality control mix design adjustments

Special exposure conditions requirements

Sustainability and carbon footprint reduction

Afternoon Session: High-Performance & Specialty Concrete (1:00 PM - 5:00 PM)

Advanced Concrete Systems:

Designing and producing specialized concrete for demanding applications including high-strength, self-consolidating, lightweight, and fiber-reinforced concrete.

Specialty Mixtures:

High-strength concrete (HSC): materials and techniques

Ultra-high-performance concrete (UHPC) technology

Self-Consolidating Concrete (SCC): rheology and mix design

Lightweight concrete: structural and insulating types

High-density concrete for radiation shielding

Fiber-reinforced concrete: steel, synthetic, glass fibers

Shrinkage-compensating concrete

Roller-compacted concrete (RCC)

Pervious and permeable concrete systems

Colored and architectural concrete

Mass concrete considerations

Cold weather and hot weather concrete

Underwater concrete placement

Workshop: Design high-performance concrete mix for specific project requirements

Day 3: Fresh Concrete Properties & Quality Control

Morning Session: Workability, Rheology & Testing (9:00 AM - 12:00 PM)

Fresh Concrete Behavior:

Understanding rheological properties, workability parameters, and fresh concrete testing methods that ensure proper placement and consolidation.

Critical Concepts:

Workability definition and importance

Rheology: yield stress and plastic viscosity

Slump test procedures and interpretation (ASTM C143)

Slump flow test for SCC (ASTM C1611)

Air content measurement: pressure and volumetric methods

Temperature measurement and significance

Unit weight determination (ASTM C138)

Setting time tests: Vicat and penetration resistance

Bleeding and segregation evaluation

Concrete consistency and cohesion assessment

Sampling procedures (ASTM C172)

Quality control testing frequency

Statistical process control (SPC) for concrete production

Afternoon Session: Concrete Production & Batching (1:00 PM - 5:00 PM)

Ready-Mix Operations Excellence:

Implementing best practices for batching, mixing, transporting, and delivering consistent, high-quality concrete from plant to placement.

Production Systems:

Batching plant types: stationary and mobile

Weighing system accuracy and calibration

Moisture measurement and compensation

Mixing equipment: drum, pan, and continuous mixers

Mixing time requirements and adequacy

Transit mixer operations and limitations

Delivery time constraints and extended setting

Concrete temperature control strategies

Quality control at batch plant

Discharge rate and concrete handling

Load ticket information requirements

Returned concrete management

Wash water recycling systems

Site Visit/Virtual Tour: Ready-mix plant operations and quality control procedures

Day 4: Hardened Concrete Properties & Durability

Morning Session: Strength Development & Testing (9:00 AM - 12:00 PM)

Mechanical Properties:

Understanding strength development mechanisms, testing procedures, and factors affecting compressive, tensile, and flexural strength of hardened concrete.

Strength Fundamentals:

Compressive strength testing (ASTM C39)

Cylinder preparation, curing, and handling procedures

Splitting tensile strength test (ASTM C496)

Flexural strength beam testing (ASTM C78)

Maturity method for early strength estimation

Core drilling and testing (ASTM C42)

In-place strength testing: rebound hammer, pullout, penetration

Non-destructive testing (NDT) methods

Ultrasonic pulse velocity testing

Strength gain curves and prediction models

Factors affecting strength: w/c ratio, age, curing, temperature

Statistical acceptance criteria (ACI 318)

Strength test failures and investigation

Afternoon Session: Durability & Service Life (1:00 PM - 5:00 PM)

Long-Term Performance:

Addressing durability challenges including freeze-thaw damage, chemical attack, corrosion, and deterioration mechanisms with preventive strategies.

Durability Topics:

Permeability and transport mechanisms

Water absorption and porosity testing

Freeze-thaw resistance and critical saturation

Scaling resistance testing (ASTM C672)

Rapid chloride permeability test (RCPT/ASTM C1202)

Chloride-induced corrosion of reinforcement

Corrosion monitoring techniques

Sulfate attack: types, mechanisms, prevention

Alkali-silica reaction (ASR): identification and mitigation

Carbonation depth measurement

Chemical resistance of concrete

Abrasion and erosion resistance

Exposure classes and durability requirements (ACI 318)

Service life prediction models

Case Studies: Analyzing concrete durability failures and remediation strategies

Day 5: Placement, Curing & Troubleshooting

Morning Session: Concrete Placement & Finishing (9:00 AM - 12:00 PM)

Field Implementation:

Mastering placement techniques, consolidation methods, finishing procedures, and joint construction that ensure quality in-place concrete.

Placement Excellence:

Pre-placement preparations and inspections

Concrete transportation and handling equipment

Pumping concrete: equipment and considerations

Placing methods: chutes, buckets, conveyors, pumps

Consolidation: internal and external vibration

Vibrator selection and proper usage

Preventing segregation and cold joints

Construction joints: location and preparation

Finishing operations: screeding, floating, troweling

Surface defects: causes and prevention

Formed surfaces and architectural finish

Slip-form paving operations

Mass concrete placement strategies

Tremie concrete underwater placement

Shotcrete application techniques

Afternoon Session: Curing & Early-Age Concrete Management (1:00 PM - 3:00 PM)

Critical Early-Age Care:

Implementing proper curing regimes and early-age protection that maximize strength development and minimize cracking and durability issues.

Curing Practices:

Importance of adequate curing on properties

Moisture retention curing methods

Water curing: ponding, fogging, wet coverings

Membrane-forming curing compounds

Plastic sheeting and wet burlap systems

Steam curing and heat accelerated curing

Curing duration requirements

Hot weather precautions and evaporation control

Cold weather protection and insulation

Early-age cracking: plastic shrinkage, settlement

Drying shrinkage and mitigation strategies

Thermal cracking in mass concrete

Curing effectiveness testing

Maturity monitoring systems

Closing Session: Concrete Problems & Troubleshooting (3:00 PM - 5:00 PM)

Problem-Solving Expertise:

Diagnosing common concrete problems, determining root causes, and implementing corrective and preventive actions for quality assurance.

Troubleshooting Topics:

Low strength investigation procedures

Surface defects: blisters, delamination, scaling, dusting

Cracking: types, causes, assessment, repair

Discoloration and efflorescence

Pop-outs and surface voids

Honeycomb and bug holes

Form blowouts and bulges

Air void system problems

Finishing difficulties and solutions

Delayed setting and flash setting

Excessive bleeding and segregation

Alkali-aggregate reaction identification

Petrographic examination (ASTM C856)

Concrete repair materials and methods

Preventive maintenance strategies

Capstone Project:

Teams analyze concrete failure scenario, conduct root cause analysis, recommend testing program, and propose corrective/preventive actions with technical justification.

Course Conclusion:

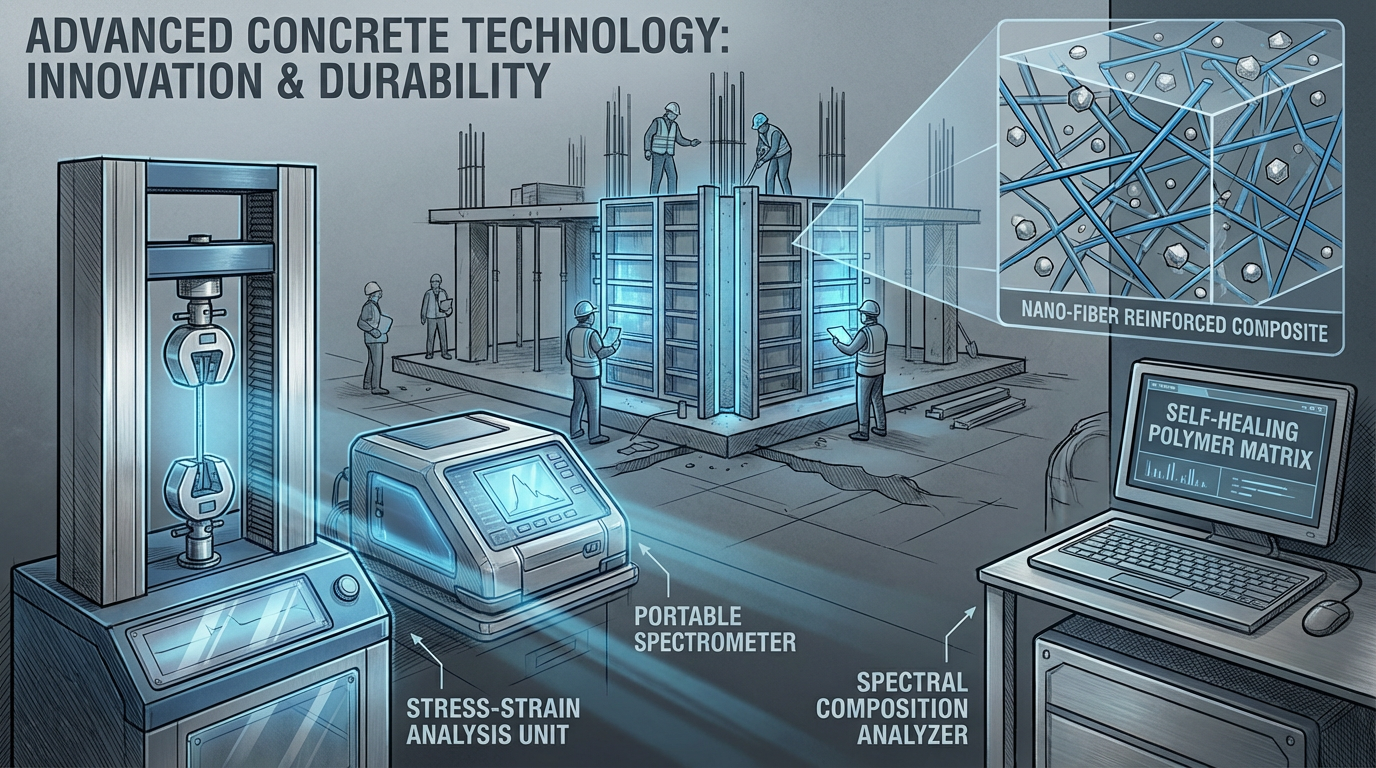

Advanced concrete technology trends and innovations

Sustainable concrete and carbon reduction strategies

Professional certifications: ACI Concrete Field Testing Technician, ACI Mix Design

Q&A with concrete industry experts

Certificate of Completion presentation (35 PDH/CEU credits)

Learning Outcomes

Participants will be able to:

Understand concrete at microstructural level and material interactions

Design optimal mixes for diverse performance requirements

Control quality through systematic testing and statistical analysis

Ensure durability by addressing exposure conditions appropriately

Troubleshoot problems systematically using technical knowledge

Implement best practices for production, placement, and curing

Specify and test high-performance and specialty concretes

Apply standards (ACI, ASTM, AASHTO) correctly

Evaluate and predict long-term concrete performance

Course Materials Included

Comprehensive concrete technology manual with reference data

ACI and ASTM standards excerpts and guidelines

Mix design calculation worksheets and software

Testing procedure demonstrations and videos

Troubleshooting flowcharts and diagnostic guides

Certificate of Completion (35 PDH/CEU credits)

Access to concrete technology resource library

Prerequisites

Bachelor’s degree in civil engineering or related field, OR minimum 3 years concrete industry experience. Basic understanding of concrete materials and construction recommended.

Keywords: advanced concrete technology, concrete mix design, concrete materials, concrete testing, high performance concrete, concrete durability, concrete quality control, fresh concrete properties, hardened concrete, concrete troubleshooting, cement chemistry, concrete admixtures, self consolidating concrete, concrete curing, ACI standards, concrete engineering course, concrete technologist training, ready mix concrete, concrete strength testing, concrete placement